Dear Sirs,

My customer asked us about I°Dial&Evm of LDC1314.

1.Can 1 ° dial application's angle calculation / display program be operated using LDC 1314 EVM?

2.Can 1 ° dial application angle calculation / display program change parameters (register contents) in the program?

3.About 1 ° dial application calibration method, please tell me the concrete method of Shape Pre-Distortion.

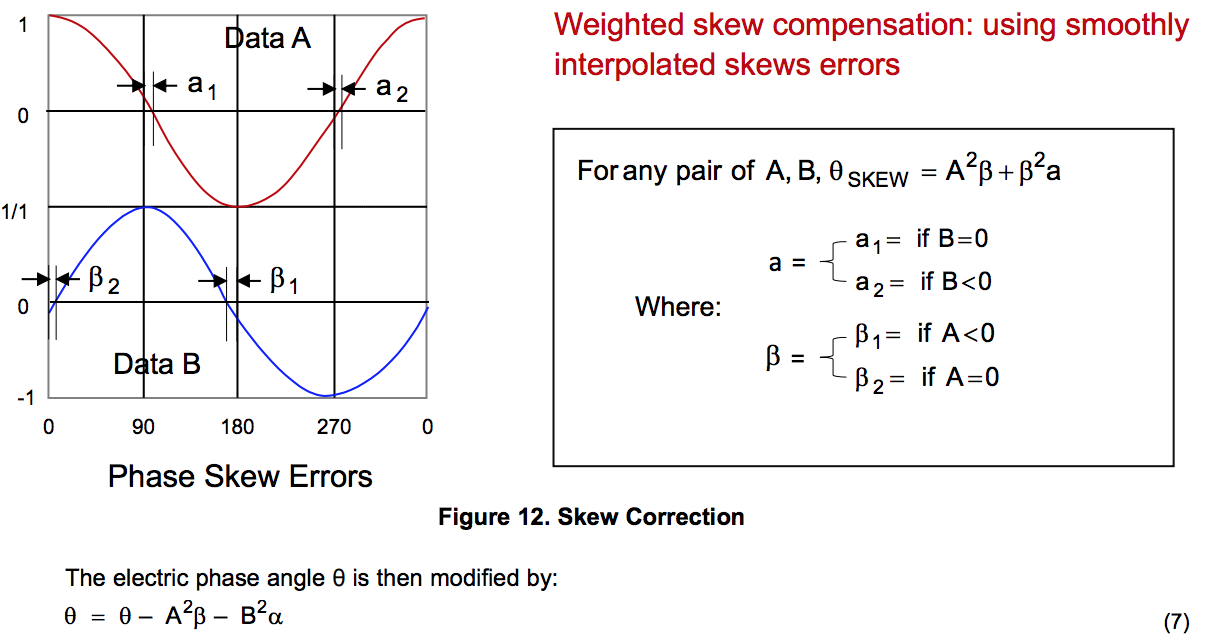

4.About 1 ° dial application calibration method, please tell me the concrete method of Phase Skew Correction.

5.In order to have customers create programs, 1 ° application program source files are required.

Could you please give me a source file.

Best Regards,

Y.Hasebe