Other Parts Discussed in Thread: LDC1614

Tool/software: WEBENCH® Design Tools

Dear all,

We are developing a position sensor using LDC1614, one of the most strict specifications is the high accuracy level required, thus we are searching for the target material which allows to reach the maximum sensitivity. Following the design notes reported in SNOA957A ("LDC Target Design") we noticed that copper and aluminum show the highest frequency shift as a function of the normalized distance (coil - target).

The questions are the following:

1)Does someone investigated the effect of additional thermal or thermochemical treatments like tempering and cementation on the electromagnetic characteristics (i.e. conductivity and magnetic permeability)?

2) Is there a comparison in terms of the frequency shift per normalized distance between copper and aluminum and other stainless steels (e.g. the AISI 416 and others)? Where it places compared to the other alloys reported in Fig. 12 (see below).

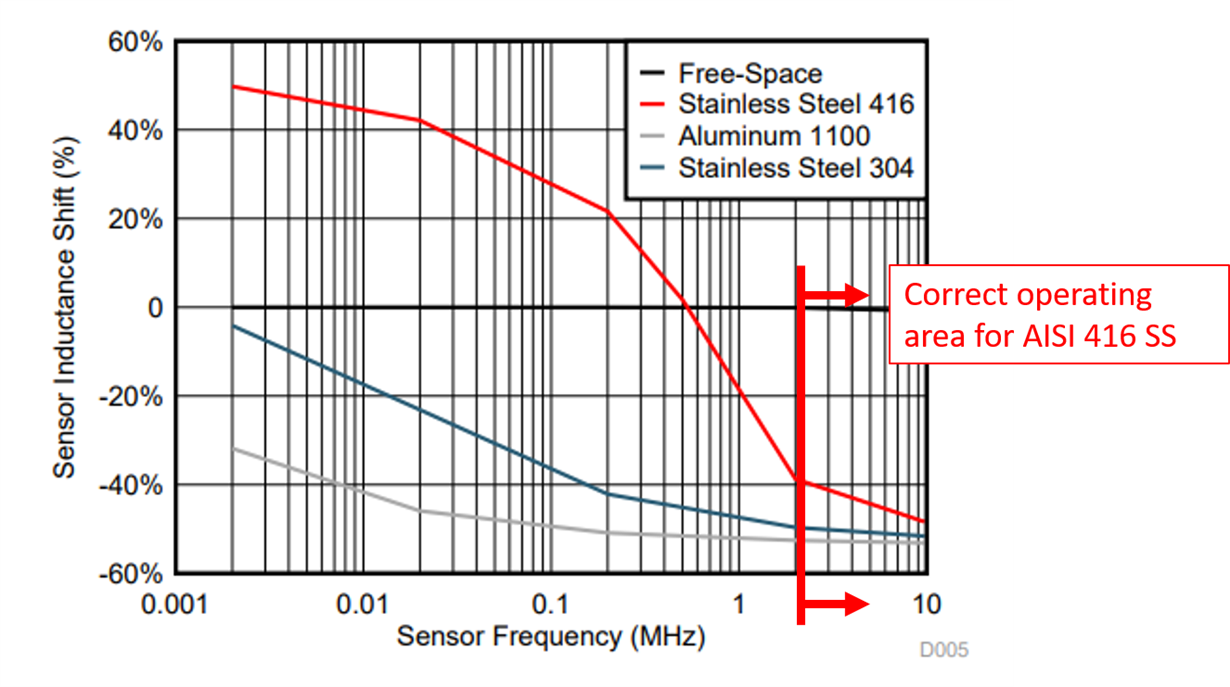

3)Taking as reference the Fig 13 of the SNOA957A (reported below), is it correct to consider the frequency range above 2MHz as the correct operating area for AISI 416 SS?

4) Are the three curves reported in Fig 13 obtained with a target positioned at a fixed distance, varying the sensor frequency ?

5) Since the slope of the SS416 curve is steeper compared to aluminum and copper does it means that the sensitivity is higher

compared to those obtained with the latter?

6) Does the steeper characteristic has a detrimental effect on the level of frequency noise (i.e. a variation of the sensor frequency reflects in a variation of the inductance)?

7) Which are the best operative point for the different materials reported?

Thank you in advance for your cooperation

Regards

Gabriele