Other Parts Discussed in Thread: , TMP117

Hello guys,

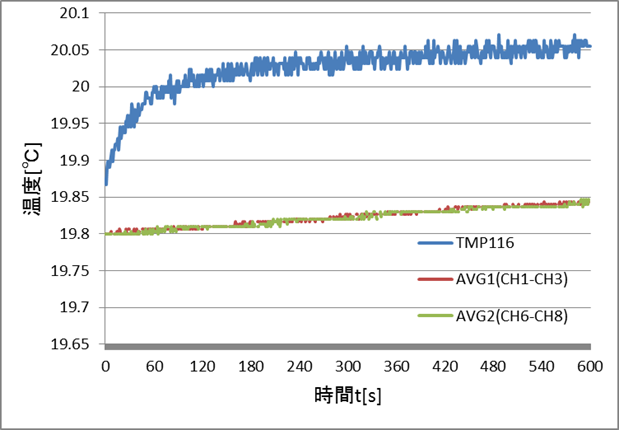

One of our customers is evaluating TMP116 using the device EVM (TMP116: http://www.tij.co.jp/jp/lit/ug/snou145a/snou145a.pdf). In their evaluation, they found TMP116 output temperature data is higher 0.21C than the data of very high accuracy thermometor they provided when Continuous conversion mode is used. Then TMP116 temperature data is 20.035C and the thermometer is 19.825C. But when one shot mode is used, the temperature data is same as the thermometer data (19.825C).

Is the cause of the temperature difference in the continuous conversion mode TMP116 self heating?

Also the device datasheet says that the temperature error with Continuoue conversio mode is about 60mC at 5V. But the error temperature the customer measured is 210mC. It is 3 times error compared with Figure 4 on page 4 of the device datasheet.

Could you please tell me your idea why the 3 times error is occurred?

Your reply would be much appreciated.

Best regards,

Kazuya Nakai.