Other Parts Discussed in Thread: PGA460, PGA460-Q1, MSP-EXP430F5529LP,

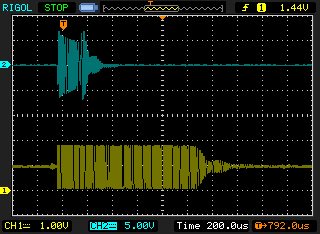

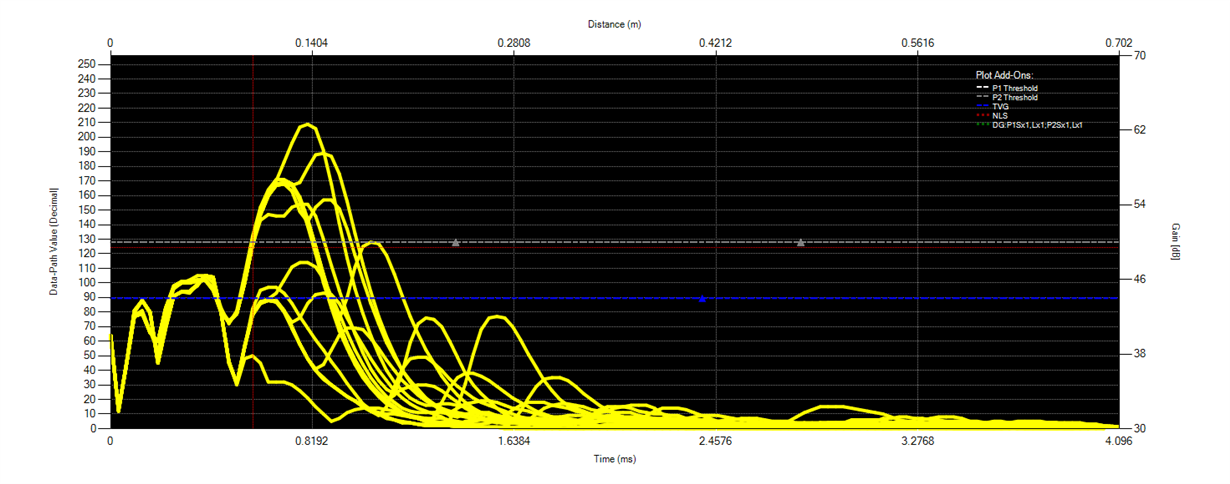

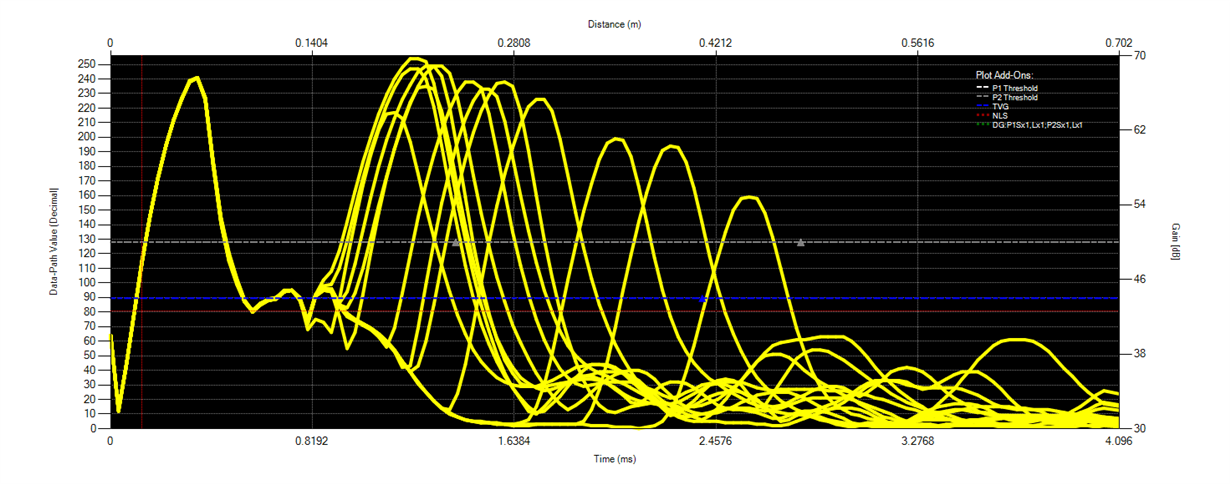

I have developed a pcb with a pga460 and all the stuff needed to generate a burst. I have got the datapath from this new pcb and I want to customize the threshold levels. I have tried to load my datapath to the memory dump screen to see it on my threshold window but I can't.

Is this possible?