Hi,

As the title suggests, I am seeing abnormal temperature readings with the LM73:

- The abnormal readings are not directly after power-on, but after a certain amount of time of valid readings. I have 10 different units and they all exhibit the failure within about 2 hours of run time, but the exact time varies.

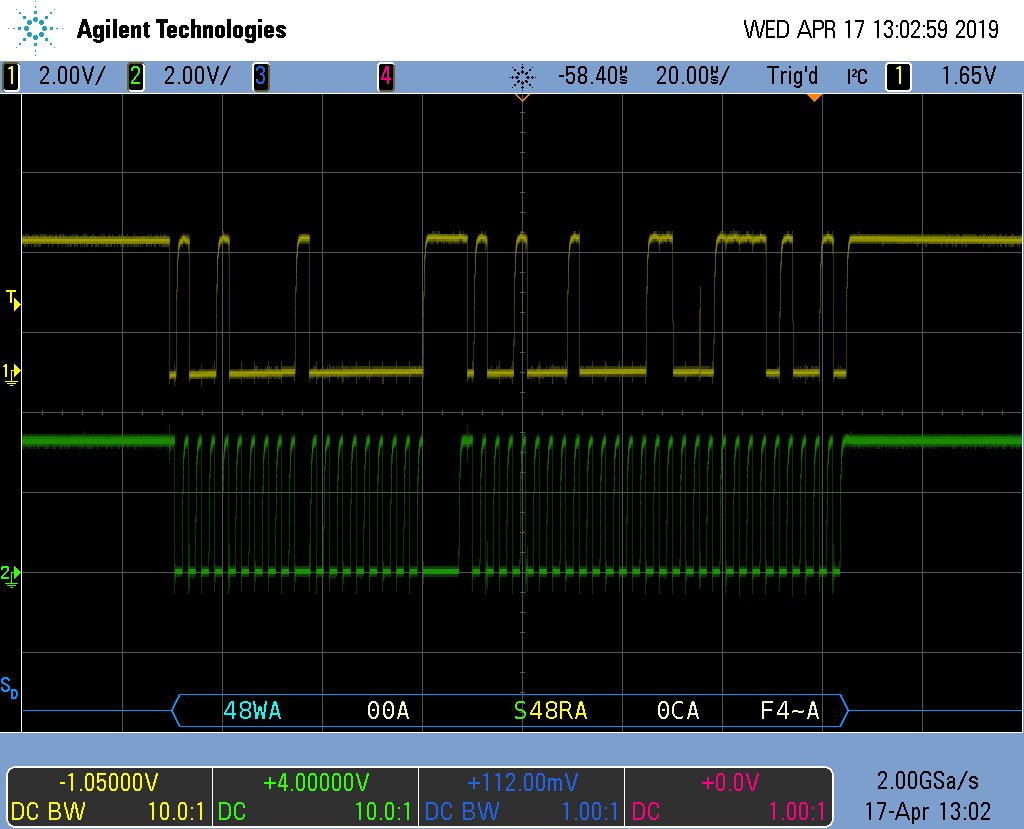

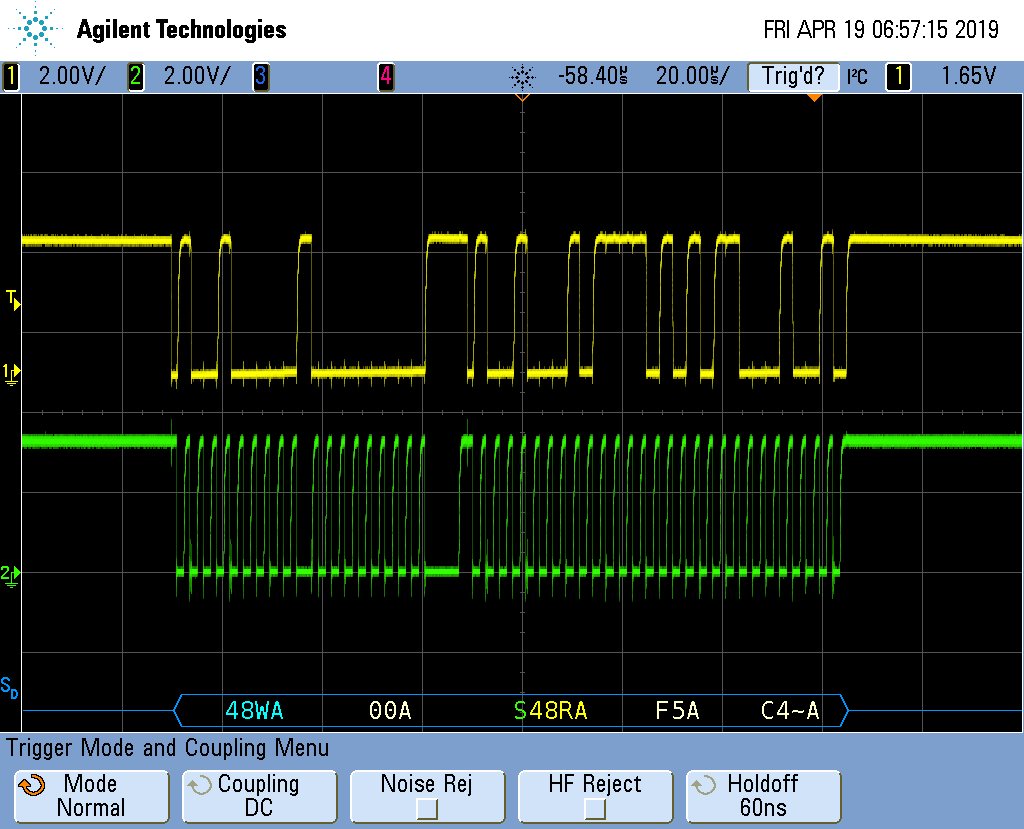

- The abnormal readings of the Temperature Data Register are usually around the same value: 0xF5XX or 0xF6XX, which corresponds with a negative temperature (around -20 degrees C). The temperature readings before the incorrect ones were around 35 degrees C. Once an incorrect value is read from the LM73, the temperature readings return to the valid range (~35degC) again.

- The problem is not I2C noise, because the microcontroller is interfacing with other I2C peripherals on the same I2C lines with no corrupted data at all. Any I2C noise would be expected to affect all devices on the same bus. The microcontroller is not seeing any problems with the I2C protocol itself (misplaced start/stop conditions, bus arbitration or NACKs).

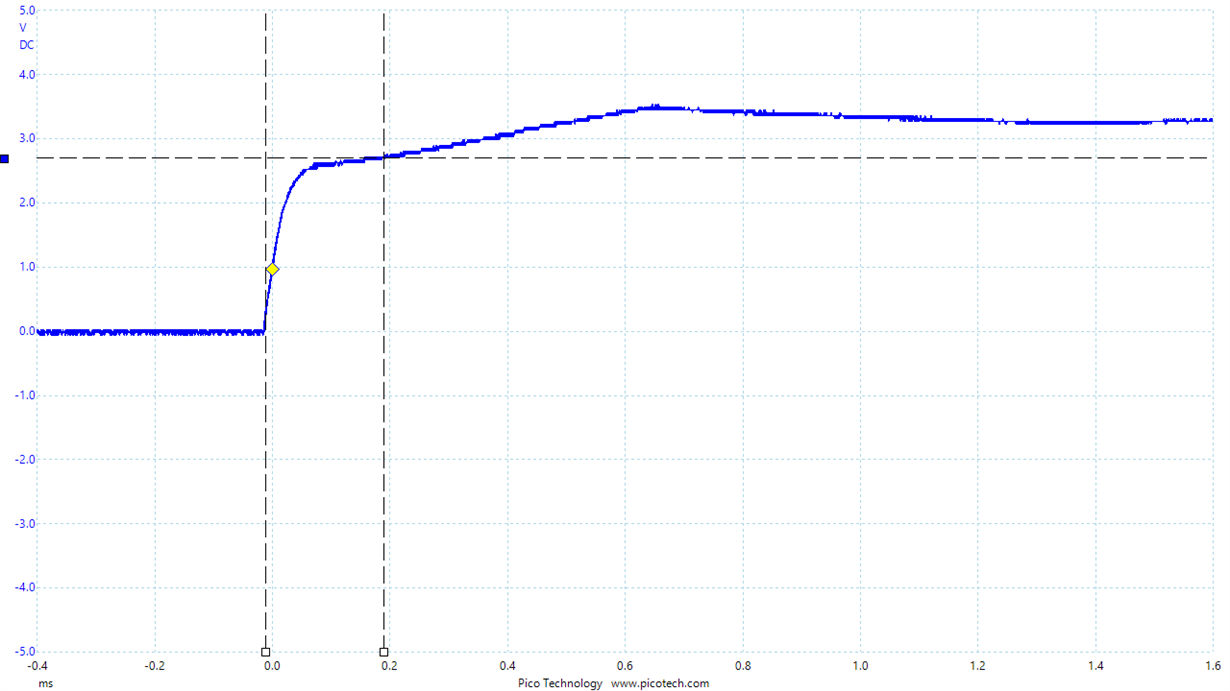

- The VDD ramp rate is faster than the minimum of 0.7V/ms specified in Section 9 of the LM73 datasheet. The VDD takes about 400us to rise from 0V to 3V3, corresponding to a ramp rate of about 8V/ms. The microcontroller software is also performing the software reset sequence in Section 9 of the datasheet, to prevent any problems with corrupted data due to POR ramp-rate.

This problem appears to be very similar to that experienced by others on this forum, however I've not been able to find a definitive answer in those posts as to why the LM73 behaves in this way.

Kind regards,

Tom