Hi!

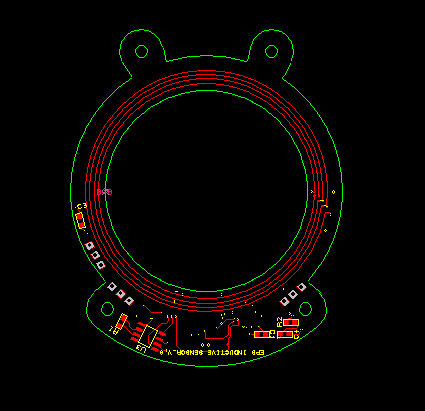

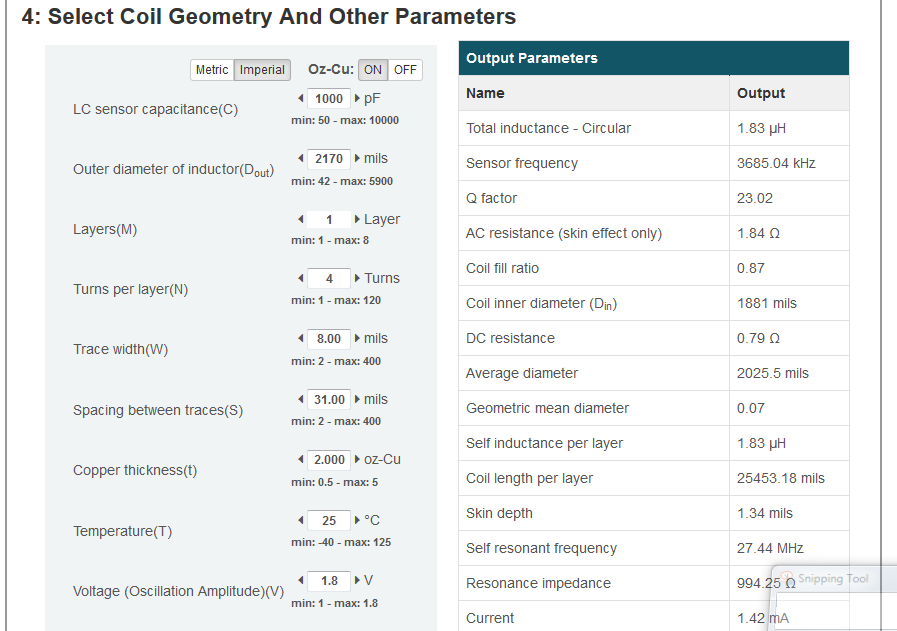

I have designed the coil as the size of d_out is 55.5mm and d_in is 49mm. I have used only one layer .

Following spec

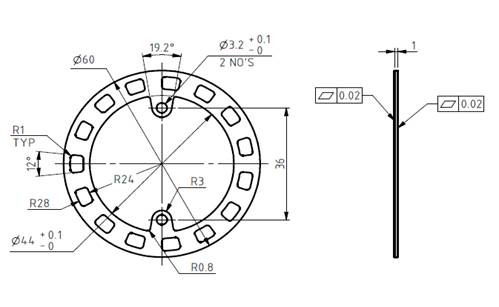

1) Coil_ outer Diameter is 55.5mm

2) Coil _inner Dia is 49mm

3) No of Turns - 4 Nos

4) Layer - 1

5) Spacing between Traces - 0.8mm

6) Coil Width - 0.2mm

Now I am operating the clock frequency as of 16MHZ.

If I touch on the sense, inductance are getting affected but with the metal not much change.

what would be the issue ? Cant we check without SPI this sensor Inductance?

what is the registers used in LDC1101

| Register | Addr | Value |

| RP_SET | 0x01 | 0x45 |

| TC1 | 0x02 | 0xDE |

| TC2 | 0x03 | 0xFD |

| DIG_CONG | 0x04 | 0xE7 |

| LHR_RCOUNT_LSB | 0x30 | 0x00 |

| LHR_RCOUNT_MSB | 0x31 | 0x02 |

| LHR_CONFIG | 0x34 | 0x01 |