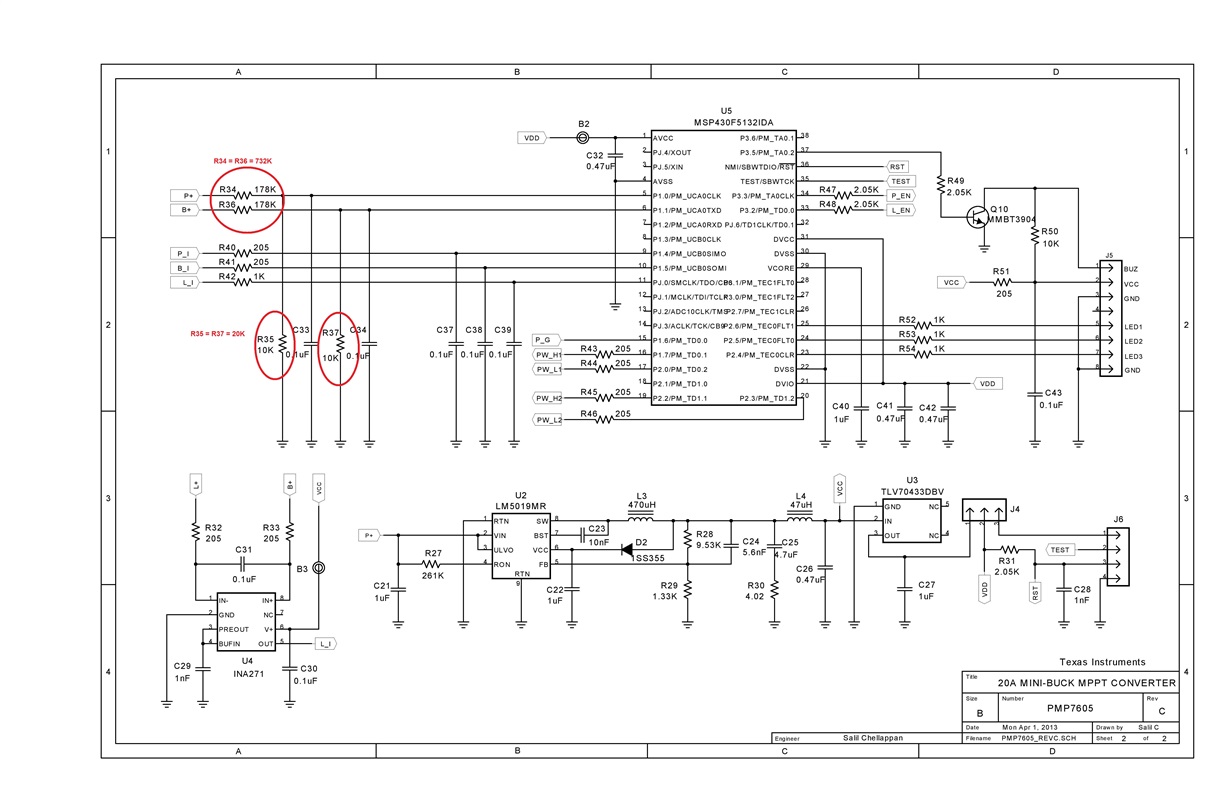

Other Parts Discussed in Thread: CSD19531Q5A, CSD19532Q5B, CSD18502Q5B, MSP430F5132

Hi,

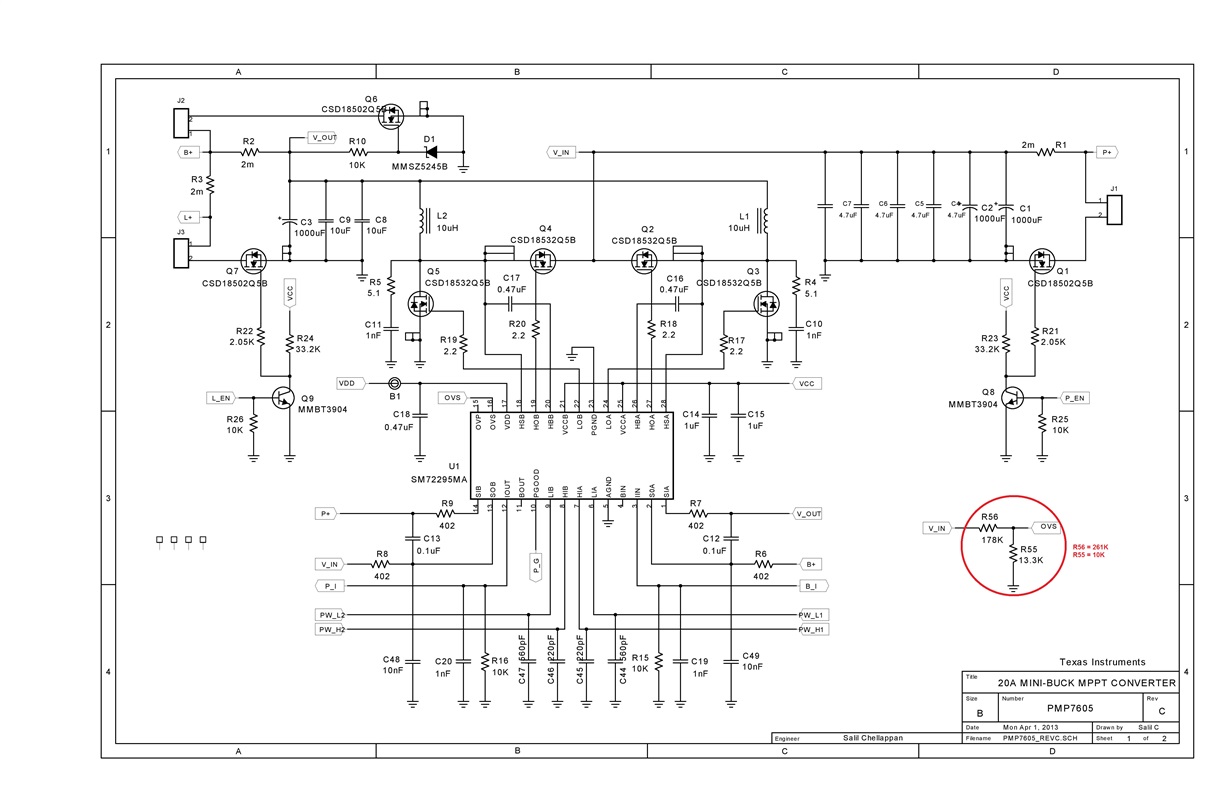

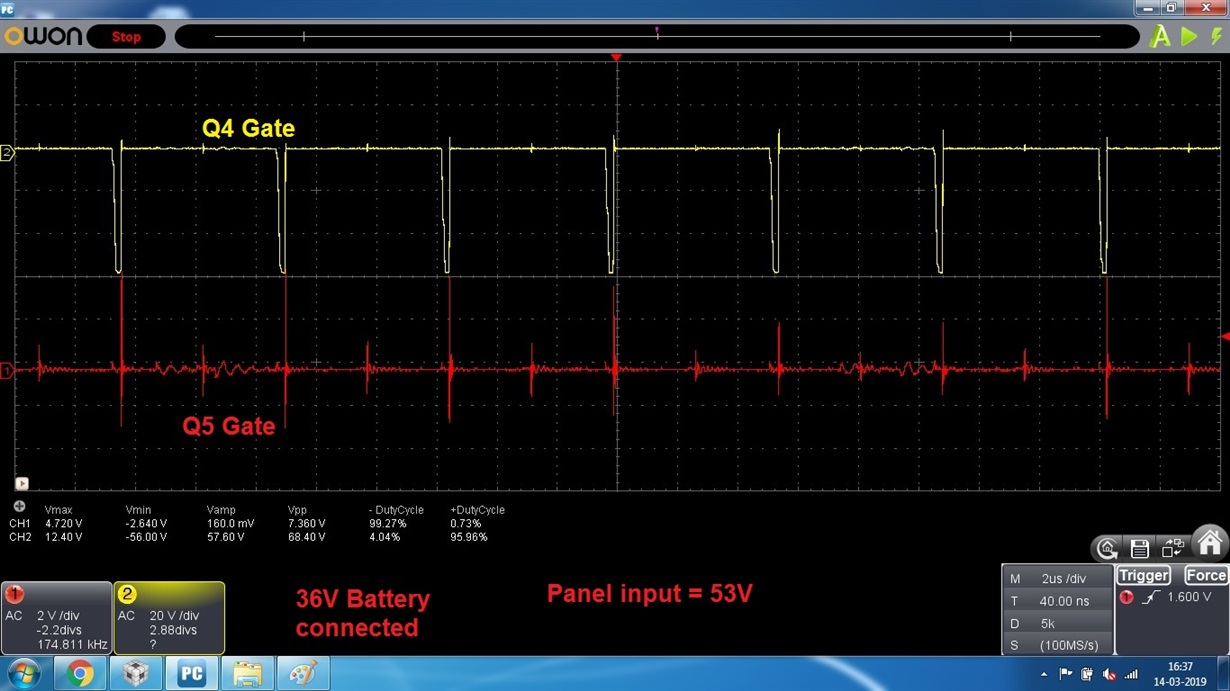

I am using TIDA-00120 reference design for MPPT solar Charge controller.

As mentioned in the test results of TIDA-00120 i tried to upgrade the design to 48V system by changing the MOSFETs to 100V.