CCDebugger won't connect to CC2541. CCDebugger works fine with the SensorTag dev kit I have, CCDebugger firmware is latest.

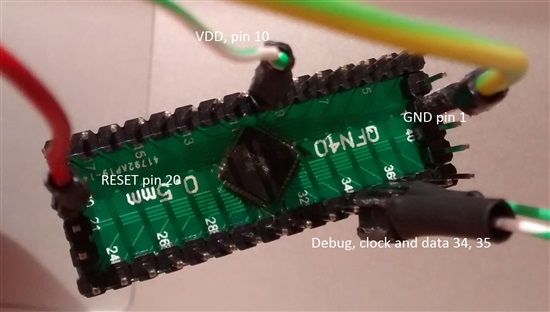

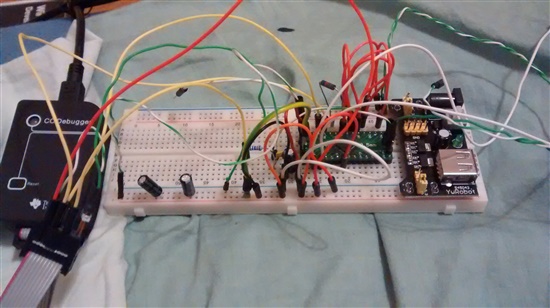

Custom board based on the CC2541-CC2590 reference design.

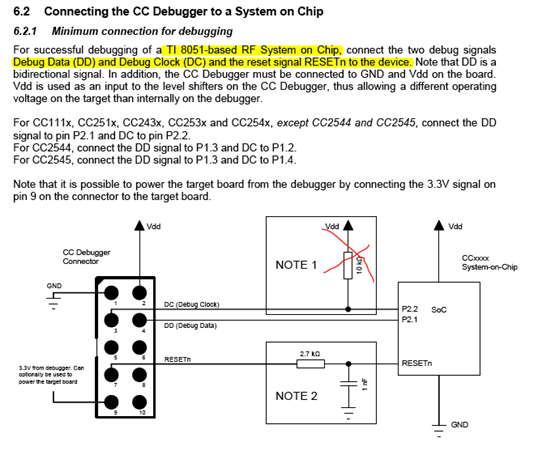

Debug pins are connected to GND, VCC, DD connected to P2_1, DC connected to P2_2, RESET connected to RESET_N (there is no filter here, could that cause the traces below?)

DCOUPL and RBIAS voltages are correct, and ground pad is soldered.

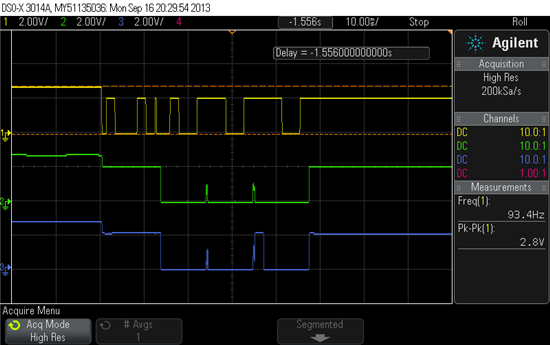

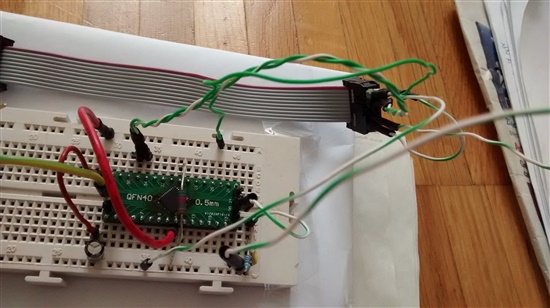

Working SensorTag: (yellow is RESET, green is DC, blue is DD)

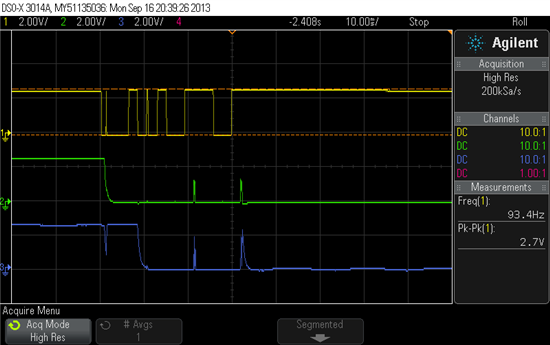

My board:

Have tried three builds of the board, all behave the same. Ideas?