Other Parts Discussed in Thread: TRF7970A

hi,

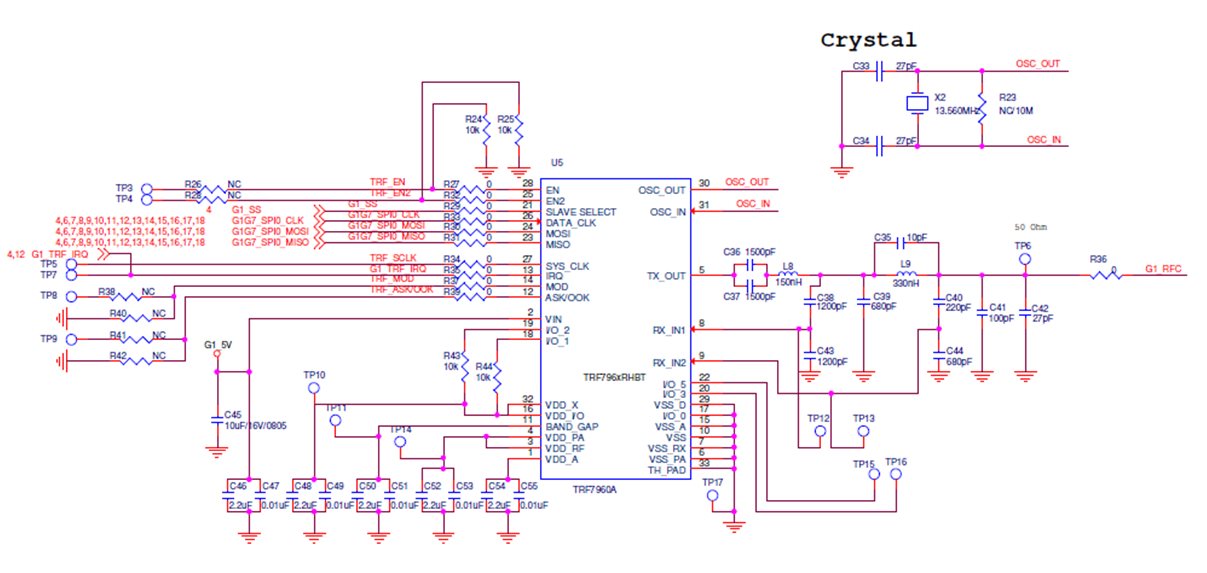

my customer design a TRF7960A + ST MCU to be an NFC Reader,

we found the IRQ pin always has no response while put a NFC card(ISO15693) near to TRF7960A's antenna.

we check the VIN +5V is normal, and the pwoer sequence of VIN, EN, SS is matached in DS, and 13.56MHz crystal is normal,

so my question is, how to initiate the TRF7960A well?

(we sent the SPI read command, but SOMI always has no data output)