Part Number: LDC0851

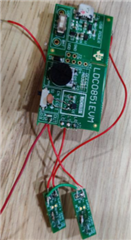

Other Parts Discussed in Thread: LDC1312, , LDCCOILEVM

Hello Team,

we want to develop inductive encoder with quadrature output using LDC0851.The dimension for target PCB is OD-45mm and ID- 42mm . we have space of 3mm to design target PCB.

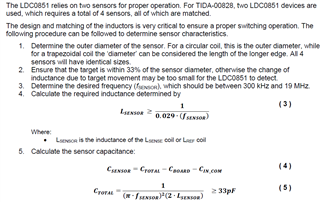

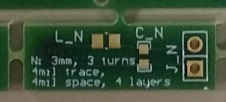

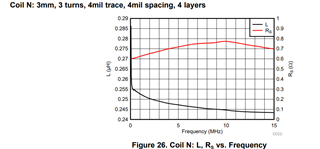

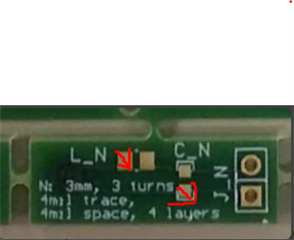

We will plot 8 slot on target PCB for 32 position ( will be using 2 LDC0851 for quadrature output). Now the main part is sensor design. we want to consider parameter for sensor design from below forum i.e 2mm sensor design .

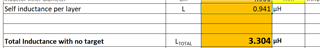

I am clear that you have used 4 layer, 3 turn that gives 150nH inductance and additional you have used 47uH inductance. this 4 layer is only for sensor coil.

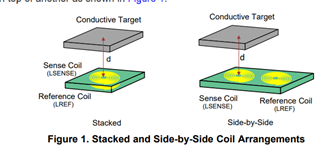

for LDC0851 it requires two coil reference and sensor . there are two options

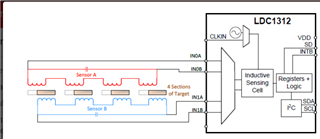

1. stack up - first two layer I will used for sensor and last two for reference. for higher inductance I was thinking of placing 4 sensor with series combination like (LDC1312 incremental Encoder Knob 32 position)

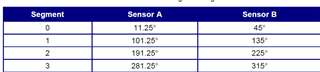

below will sensor position placement for 2 LDC0851

2. side by side - for this all 4 layer will will be sensor and side by 4 layer will be reference . for this is it ok if I plot 4 sensor and 4 reference for higher inductance in series combination.

for series combination I will use above sensor position but then what will be position for reference coil.

can you suggest which option will be better.

Regards,

Sayali