Tool/software:

Hi TI engineer,

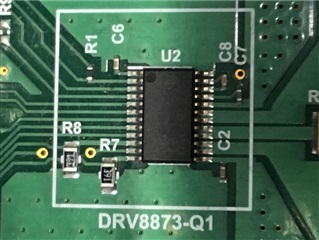

The DRV8873S-Q1EVM is used to drive the motor, and the current is measured by an external ammeter.

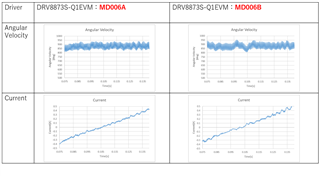

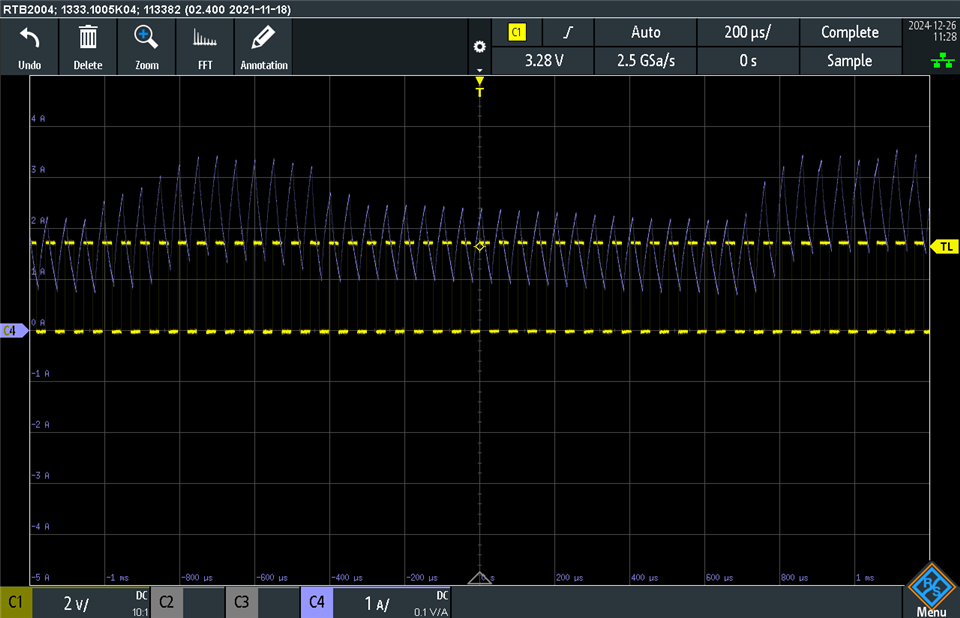

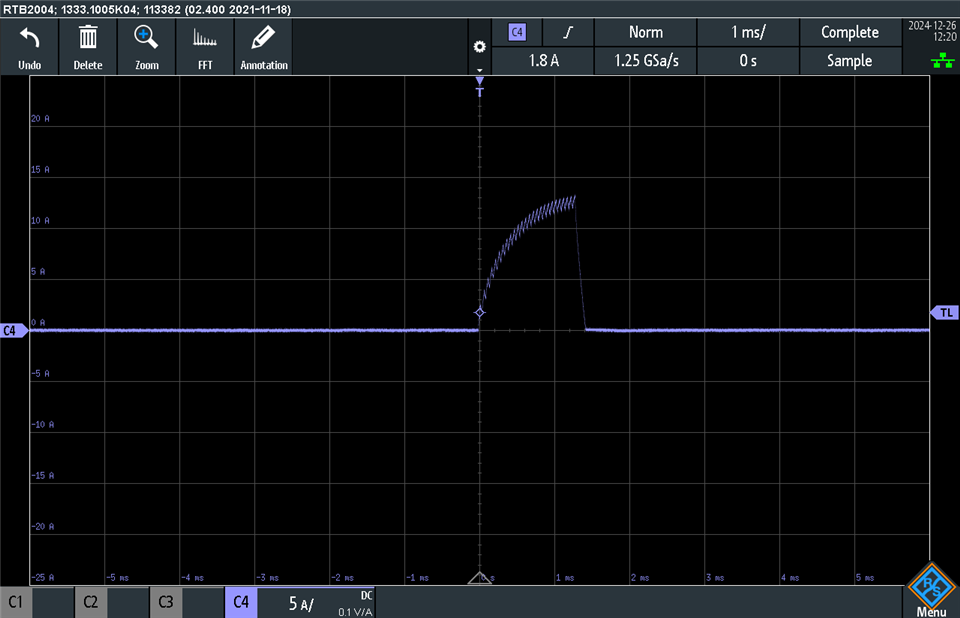

When we prepared 2 configurations of controller →DRV8873S-Q1EVM and measured the current of the same motor, there was a difference in the current waveform, and when we investigated, one of DRV8873S-Q1EVM was MD006A and the other was MD006B.

From the above, I would like to ask the following two questions.

・MD006A and MD006B Changes

・Is there a possibility that the motor current waveform changes between MD006A and MD006B?

(Supplementary Explanation)

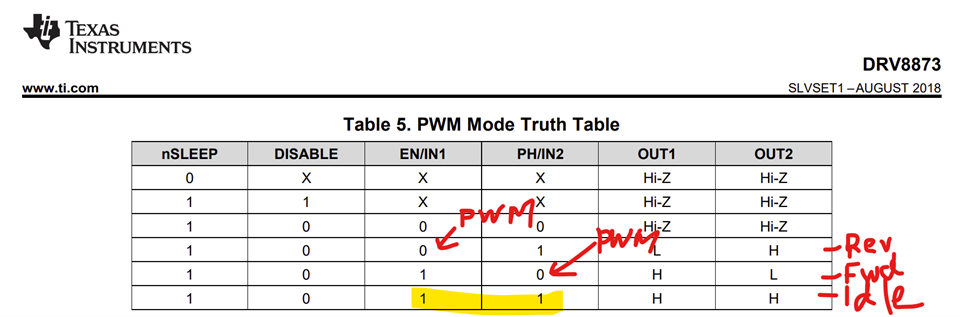

The PWM signal of the controller is connected to the pin near the center of the DRV8873S-Q1EVM and driven by PWM control.

The power supply is set to 7V/3A.