Yeqin Wang is pursuing his Ph.D. in the Wind Science and Engineering Program at the National Wind Institute at Texas Tech University. With about eight years of experience with TI C2000 microcontrollers (MCUs), Yeqin shares his experience with his most recent project that was a part of the MATLAB and Simulink Hardware Challenge.

The facts

Did you know that wind turbines not only produce power, they produce wakes? Similar to the ripples you would see in a body of water, wind turbine wakes are invisible ripples, waves, and other disturbances in the atmosphere downstream that can damage turbines and decrease efficiency.

Photo courtesy of Vattenfall

The problem

With these wakes decreasing efficiency, how do you control them? Most solutions proposed by researchers focus on specific wind turbine arrays and only take into consideration steady, unchanging conditions in both the environment and turbine. Given the inherent unsteady nature of the incoming turbulent inflow and the fast dynamic changes in speed, the pitch angle corresponding to yaw input should be considered. Exploring innovative strategies in full-scale turbines (many of which are higher than 328-feet) are impractical and expensive, and may not be available for iterative development of wake control strategies.

HAWKS: A proposed solution

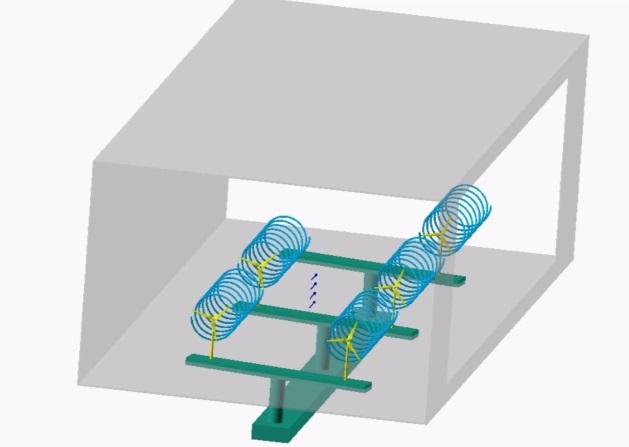

To emulate the full-scale physics of controlling wind wakes in real-time, “Hyper Accelerated Wind Farm Kinematic-Control Simulator” (HAWKS), a platform with multiple functional and programmable wind turbines is being built at the National Wind Institute (NWI) at Texas Tech University (TTU). The HAWKS platform sits in a boundary layer wind tunnel, which can produce complex wind profile inputs. HAWKS aims at being a platform to test wake steering control strategies to improve wind turbine array output. HAWKS measures wake characteristics which are then input to the turbine controller to produce the desired downstream effects.

(Above) – The HAWKS Wind Farm in Wind Tunnel.

Challenges

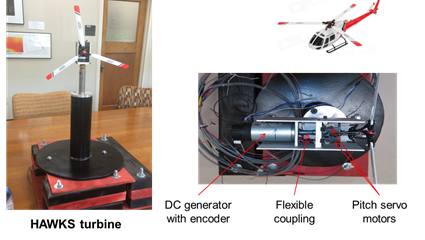

One of the challenges in this project is that we needed to build everything from scratch, starting with the actual wind turbine designs to the final product with full controls. The team selected the blades and pitch control hardware from a model toy helicopter, a DC motor (performing as a generator) was enclosed in a nacelle integrated with the blades and pitch hardware, and the yaw system was driven by a servomotor Futaba S9155.

(Above) – The HAWKS Turbine Design.

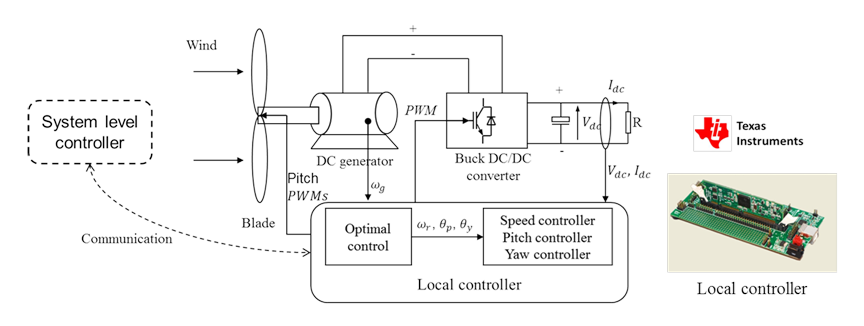

By adjusting the duty cycle of the DC/DC buck converter, the rotor speed is controlled. Such control of the rotor speed, pitch and yaw angle are important capabilities of the HAWKS turbine in order to achieve multi-level operating conditions. We chose TI’s TMS320F28335 MCU control kit as the turbine controller, as it includes resourceful peripherals. The 32x32-bit MAC 64-bit processing capabilities can handle high numerical resolution problems efficiently in wake calculation and control. We used MathWorks Simulink to develop our algorithms and Embedded Coder to generate ANSI C code that can be directly compiled using TI’s Code Composer Studio (CCS) integrated development environment (IDE). This development process automates many of the time-consuming programming tasks and enabled us to test our system designs and algorithms in a fast and flexible way.

(Above) – The HAWKS Turbine Control.

Results

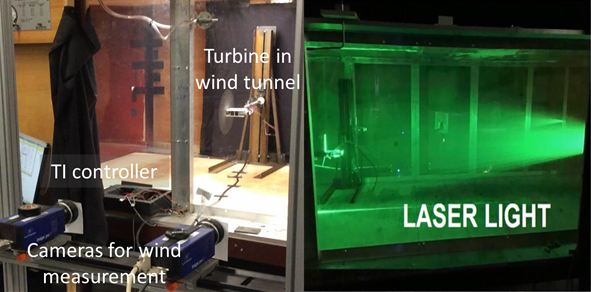

The wake measurement of a single HAWKS turbine was carried out in a closed-loop wind tunnel with a uniform inflow velocity. The technique used was Particle Image Velocimetry (PIV) to measure the velocity distribution across a planar area of the flow field downstream of the turbine. A laser system was used to illuminate the flow seeded by a particle generator using propylene glycol oil droplets. The particle images were recorded with an array of four 14-bit La Vision CCD cameras. The wake images were processed using standard La Vision software.

(Above) - HAWKS Turbine Test Environment at NWI, TTU.

Conclusion

The single HAWKS turbine has been built and full dynamic control functions have been achieved with the help of TI’s TMS320F28335 MCU. The turbine performance and controls have been tested in the wind tunnel environment. The results have demonstrated the wake steering for both static and dynamic yaw conditions. We are currently continuing work on a full-scale HAWKS, and will implement our results into the real wind farm upon completion.

Watch the HAWKS project in action

Learn more about TI MCUs

Learn more about MathWorks support for TI C2000 MCUs

References:

[1] R. Castillo, Y. Wang, etc., “PIV measurements in a real-time controlled model wind turbine wake simulator,” Journal of Physics: Conference Series, 2016.

[2] R. Castillo, Y. Wang, etc., “PIV measurements in the wake of a dynamically controlled model wind turbine,” Presentation, WINDFARMS Conference 2016.