Picture this--You are designing your company’s latest and greatest water meter and have been asked to increase its battery’s run time by 10% over the previous model. This is now the fourth product that your boss has asked you to do with this feat. You’ve already improved the power supply’s efficiency, used excellent low-power coding techniques in the microcontroller, and stripped out all of the extra functionality. There’s nothing left to improve! Do you completely change the architecture, use a completely new microcontroller, or move to a different battery type? Each of these options will take far too long for your end of year deadline. What can be done?

Perhaps, your current design still leaves significant energy in the coin cell battery because your power supply is unable to extract it all for the system’s use. For instance, the meter may declare the battery used up when it gets down to a 2.3-V open circuit voltage, since this is the minimum voltage required to operate a motor or MCU. What if you could lower this battery voltage to 2V, 1.8V, or even 1.5V? That’s a relatively huge amount of energy left to extract from the battery! How can you efficiently use this extra energy and meet your 10% run time extension goal? As I explain in the Electronic Design article, “Extend Battery Life with Boost-Plus-Bypass Operation,” an ultra-low power boost plus bypass device enables this run time extension.

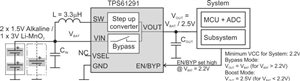

The TPS61291, low Iq boost converter with bypass operation, allows the system to operate as it currently does with higher battery voltages. In this bypass mode, the battery voltage is fed directly to the output with minimal losses. You only need to provide an extra 15 nA for the boost plus bypass device to operate. You may not even be able to measure such a low current!

With lower battery voltages, the system microcontroller turns the boost plus bypass device on. It boosts the battery voltage above the minimum required by your system—perhaps 2.5V. In this mode, a higher current is drawn from the battery, but the system is supplied with sufficient voltage, while the battery continues to discharge. The system now can operate down to the cutoff voltage of the battery, not the cutoff voltage of the system.

Keeping your same design and power source, a boost plus bypass device allows your system to operate down to lower battery voltages, extending the run time. Way to go!

What other coil cell or 2x AA applications would benefit from this technique?