When you are designing a circuit to charge a Lithium-ion battery, what is the right value of over-voltage tolerance for the charger or front-end power-input device?

The answer (as usual) is, “it depends.” What is your normal direct current (DC) input to the charging circuit? Are you using a regulated or unregulated power source? Do you have a long cable to connect from your power source to the battery-operated product?

Let’s look at the typical case of a 5V wall adapter (like a USB source) and cable (say, roughly 1 to 2 meters) connected to a portable device. You might think that a 6.5V or 7V maximum input rating for a (typical) 5V power input would be “good enough” to give a bit of safety margin for your circuits, allowing for power-source tolerance and/or transients and noise on the power rail.

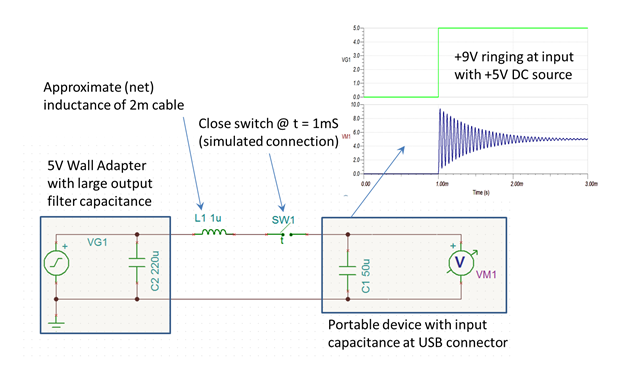

This may be true for most components within an electronic product, but a battery charger turns out to be a special case. Because the +5V power source is connected to the device through a cable, the parasitic inductance of that cable can cause a high transient “ring” voltage when plugged in. While there can be quite a lot of variation in the effective inductance of a given length of cable (due to wire gauge, orientation, materials, etc.), a typical setup can have enough inductance to result in a peak voltage at the input connector of over 2x the steady-state DC value. Therefore, chargers designed for 5V input sources should have >10V input-voltage ratings – preferably higher. Figure 1 illustrates a simple model of a 5VDC power source connected to a device with a cable.

Figure 1: Simplified system model using TINA software

Exceeding the charger’s input rating – especially on a repeated or long-term basis – will cause the device to eventually fail and the entire product to become unusable. While adding a little bit of “headroom” or safety margin to the input power stage of a charger does increase the die area of the device, the added cost is relatively minor – especially compared to the cost of replacing your entire product.

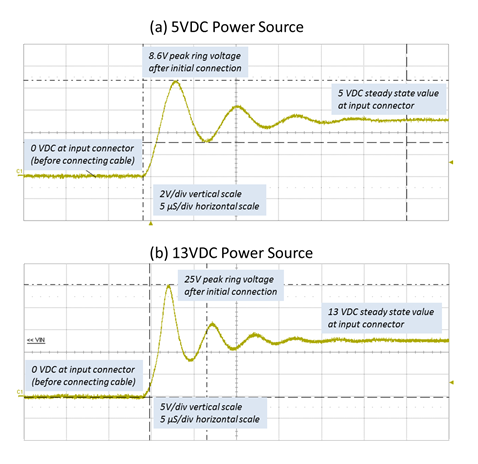

The two oscilloscope traces in Figure 2 show actual lab test results when connecting nominal 5VDC and 13VDC power sources to a device through a 2m cable measured at the device’s input connector. The transient peak measured at the device input gets up to nearly double the steady-state value, so the charging IC must be able to tolerate this repeatedly.

Figure 2: Hot-plug transient at device input using a 2m cable from a DC source

Most of TI’s single-cell lithium-ion charger devices (like the bq24196 (2.5-A), bq24296 (3-A), bq24192 (4.5-A), bq25892 (5-A)) have absolute maximum input-tolerance values of 20V or more. This enables safe and reliable operation with inputs ranging from 5V to 12V, as well as operation from semi-regulated or unregulated power sources. We’ll be publishing an application note soon to explain more of the details of hot-plug transients and input over-voltage-protection ratings on our battery charger solutions overview page. Be sure to check back in a few weeks.

Additional resources:

- Read our last post on battery charging design: Selecting the right battery charger for industrial applications