Several new battery charging devices were introduced for low power and wearable applications in past Fully Charged blogs In fact, a real power solution of a wearable device includes a lot more components than just a battery charger. Now let’s look at some of the most popular devices to be considered when designing the charging solution of your system.

Different power sources can be used in the front end of the battery charger as the input, including normal USB and AC adaptors, wireless power and energy harvesting. Over the years, TI has been closely working with the Wireless Power Consortium (WPC) and there are several TI wireless charging transmitters and receivers that can be used in both Qi or non-Qi certified solutions.

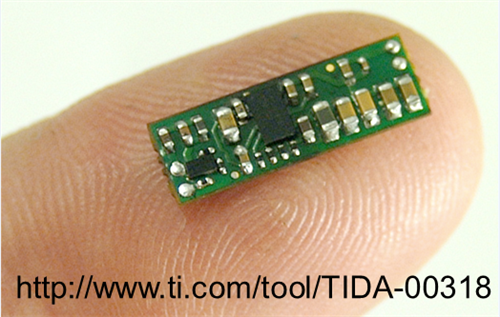

The tiny wireless receiver for low power wearable applications TI Designs reference design, is an ultra-small reference design using low power wireless receiver bq51003 and provides the 5V DC input to a battery charger. The total solution size is less than 30mm2 and is ideal for space limited low power applications. If a direct charging solution is preferred, the bq51003 can be replaced with bq51050B which integrates battery charger and can be connected to a battery directly.

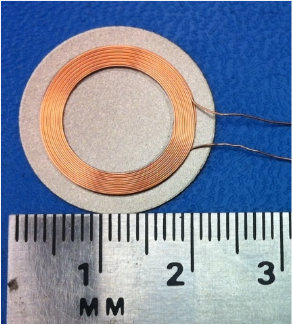

The Qi (WPC) compliant wireless charger for low power wearable applications TI Designs reference design, paired bq51003 with low power charger bq25100 and the tiny10mm coil and formed a total receiving side wireless charging solution that can output up to 2W power. The bq25100 is designed specifically for wearables charging, allowing the solution to achieve very accurate charging termination and less than 75nA all time battery leakage current.

The small wireless power transmitter for low power wearable applications, TI Designs reference design, is the application circuit of TI’s low power transmitter bq510212A. It is the perfect companion of bq51003 in wireless charging. In order to achieve reasonable overall system efficiency, the coil size in the application circuit is 30mm2 instead of 10mm used which is used in the receiver side of other reference designs. This solution is not Qi certified because the coil size is non-standard. In a proprietary design, non-compliant RX and TX can still communicate with each other and you get more freedom in choosing coils and other related components. Check out the video from Dick Stacey for a high level introduction of TI wireless power solution for wearables and fitness devices.

The other power sources that people talk about quite often recently come from energy harvesting. Energy harvesting systems collect the energy from light, thermal, and vibration sources and save it in energy storage units such as super-capacitors and small batteries. Because a large number of wearable applications are used in outdoor activities, it naturally provides the possibility of utilizing the sun light and converting it to the energy that can be used to power up the wearable devices.

TI offers several low power, high efficiency buck and boost converters in this area: bq25570, bq25504/05 and TPS62736/37. We will talk about those devices in more details in an upcoming Fully Charged blog post, stay tuned.

In my previous blog post 3 frequently asked questions about charging wearables, I talked about the three most popular battery chargers that can be used in wearable applications. It can be used as the first pass selection criteria for a low power linear battery charger.

Let’s also not forget another very important element in the system – the battery fuel gauge. In wearable applications, the battery capacity is typically small. Smaller batteries require accurate control of charging termination to prevent over-charge degradation to the battery. A fuel gauge uses a sense resistor to more accurately monitor the charging current and so a host could monitor the gauge’s current and disable the charger more precisely to ensure fuller as well as healthier charging. The bq27421-G1 is TI’s lowest power fuel gauge that can be used with single cell li-ion batteries and its small 1.6mm by 1.6mm size (including integrated sense resistor) is ideal for space-constrained solutions. This device also has several power modes for power efficiency: Initialization, normal, sleep, hibernate, and shutdown. In shutdown mode, the gauge sips only 600nA, which is negligible compared to the cell self-discharging rate. The patented Impedance Track™ technology offers ease of configuration and flexibility of battery pack selection. For battery chargers with less accurate termination control, a proper fuel gauge device can be a very good complement to maximize the utilization of the small battery capacity.

To find out more information about wearables charging solutions from TI, please visit:

Industry-Leading Wireless Power Solutions

Designing a Qi-compliant receiver coil for wireless power systems, Part 1

Low Power Transmitter Reference Design, bq500211 (Rev. A)

Low-Power, Long Runtime Battery Fuel Gauging Scheme