Imagine for a second how useful (or useless) your car would be without a gas gauge. Not very appealing, is it? The same principle applies to battery-powered systems. Including a gas gauge in a battery-powered system provides accurate capacity information and helps extend the runtime of the application.

TI provides multiple solutions for single- and multi-cell applications, with gauging algorithms such as Impedance Track™ and Compensated End-of-Discharge Voltage, CEDV. But where should you place the gauge?

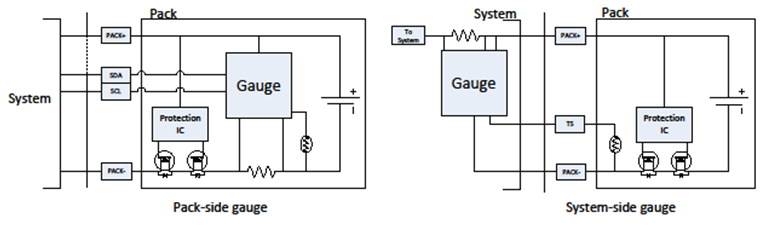

When designing with gas gauges, the designer needs to choose the cell count, chemistry and whether to place the gauge inside the battery pack or on the system board. Each alternative has advantages and trade-offs, depending on the application.

Figure 1. Pack-side and System-side configurations

Gauges have typically resided inside battery packs. This configuration allows the gauge to monitor the battery continuously without losing power and to provide constant feedback to the system host about battery status. Another benefit of integrating the gauge inside the battery pack is the ability for the gauge to log lifetime data about the battery (similar to a black box) to help diagnose packs for warranty or troubleshoot any erratic behavior.

Since the gauge is integrated, it is able to be optimized to a particular cell model. But since the gauge is always on, it also acts as a constant load on the battery itself; TI battery gas gauges include low-power modes to help alleviate the gauge’s impact on battery runtime. Security measures can also authenticate battery packs and ensure packs optimized for the application are used.

For applications where you want to give consumers the ability to swap battery packs but still want to provide high-accuracy gauging information, consider system-side gauges. These gauges reside on the system board; they can detect battery-pack insertion events and quickly estimate the initial capacity and runtime of an inserted pack. They also provide more general purpose input-output, GPIO functions to make host communication more efficient via interrupts and decreased polling.

Regardless of your application, there are options available to integrate gas gauging in your battery-powered systems. A quick pros and cons analysis can help you choose which gauge is a good fit for your next project. For more details about gas-gauge selection, read “Selecting an Impedance Track Gas Gauge for Li-Ion Single Cell Applications”

Additional resources

- Read the blog post: Batteries get smarter with intelligent gauges

- Watch these videos to learn more about Impedance Track technology: