Other Parts Discussed in Thread: OPA1642, OPA1622

Dear TI Support Team,

I would like to clarify some points with INA1620 when using it as Headphone Amplifier.

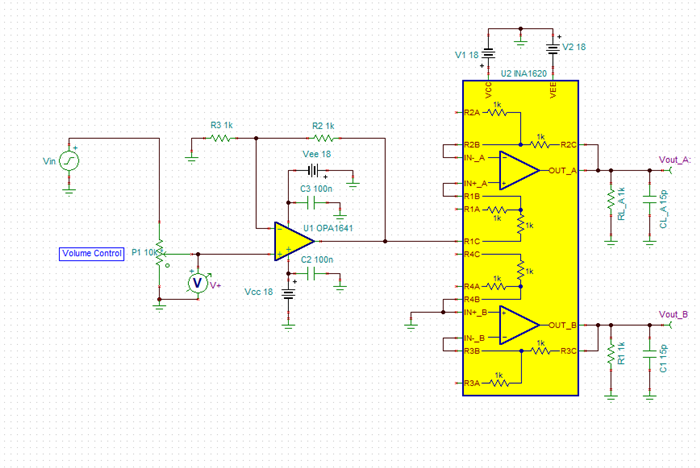

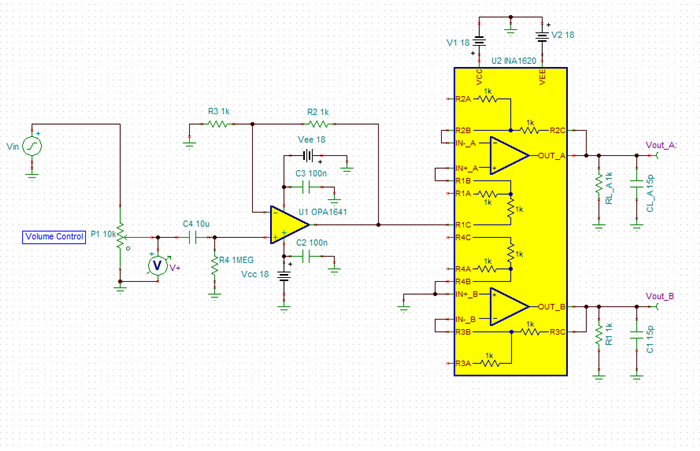

1. According to schematic attached, the Active LPF analog output is first connects to 10K volume pot and then goes to INA1620 noninverting inputs. INA1620 is configured in a unity gain.

My question are:

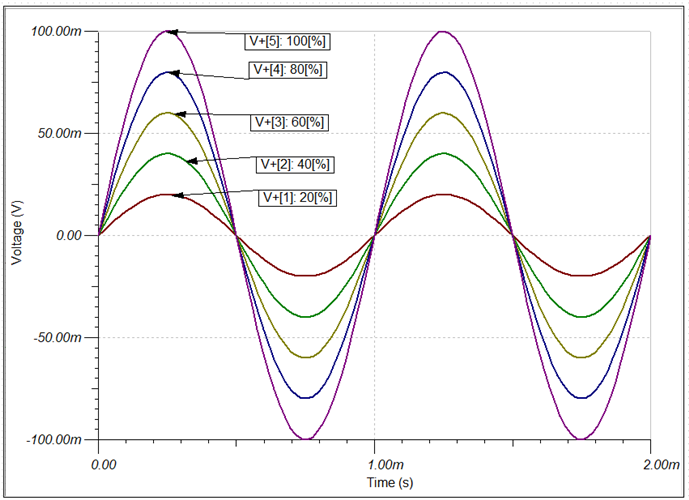

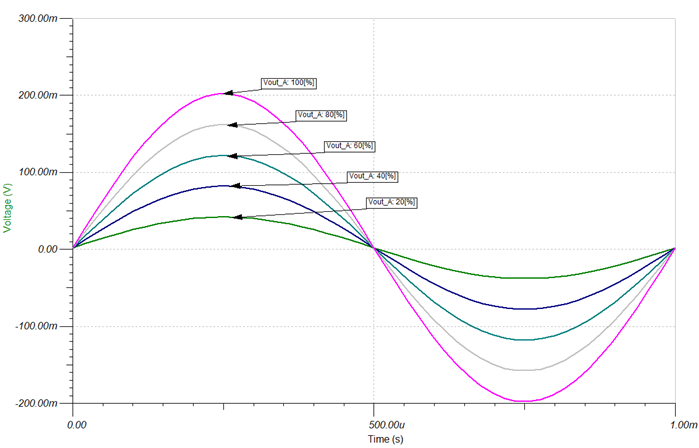

1.Does the performance and sound quality of INA1620 effected, taking into account that the pot has variable resistance and INA1620 has its own internal 1K resistor and the combined resistance always varies.

2. In some forum threads I read that it's recomended to place an OPAMP as a buffer before the INA1620, is it correct to do so?

3. If placing an OPAMS is correct, then could you please recomend or help me alter the schematic attached including the components nominals, so that it lets me use the INA1620 to its full potential.

Thanks and best regards,