Hi team,

For PGA207 layout, here is an design item want to confirm with you.

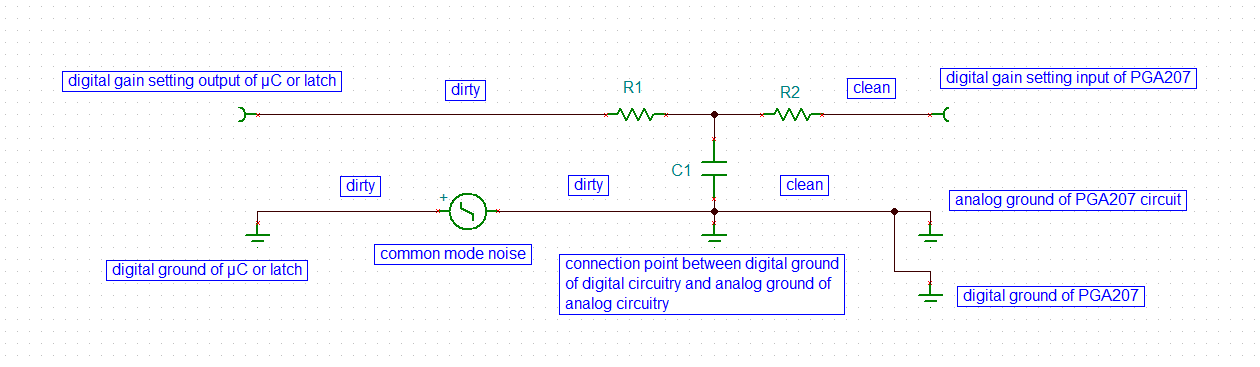

There is a description as following saying the digital ground should return through a seperate connection.

But for the real case, my customer want to know whether they could use one GND plane directly for simple layout? If there is any side effect here?

Thanks

Best regards

Mia Ma