Dear TI Team,

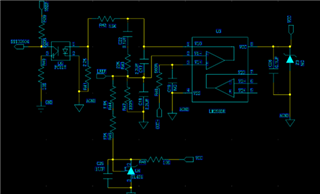

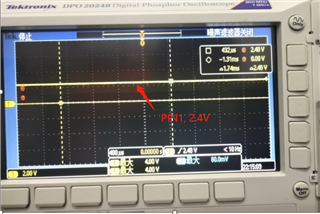

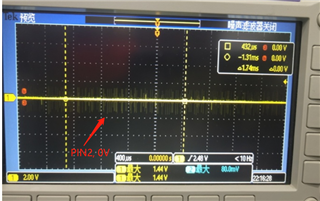

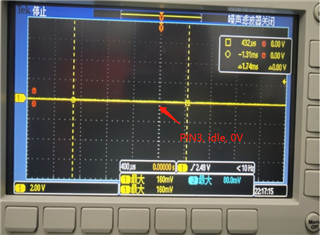

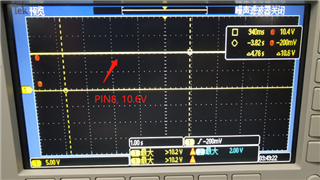

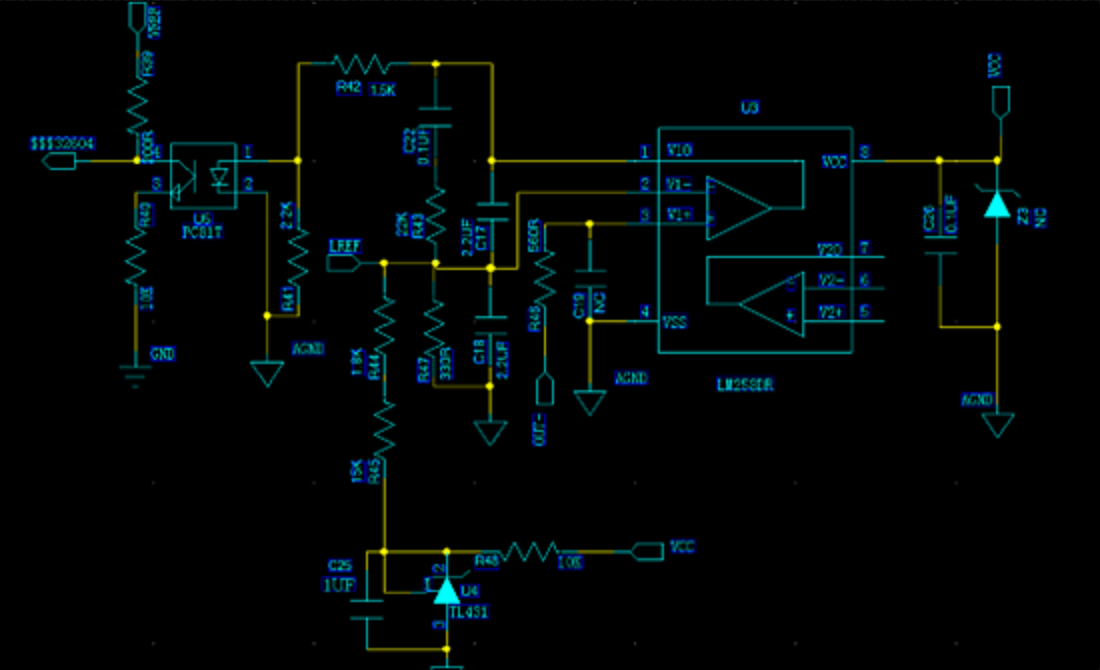

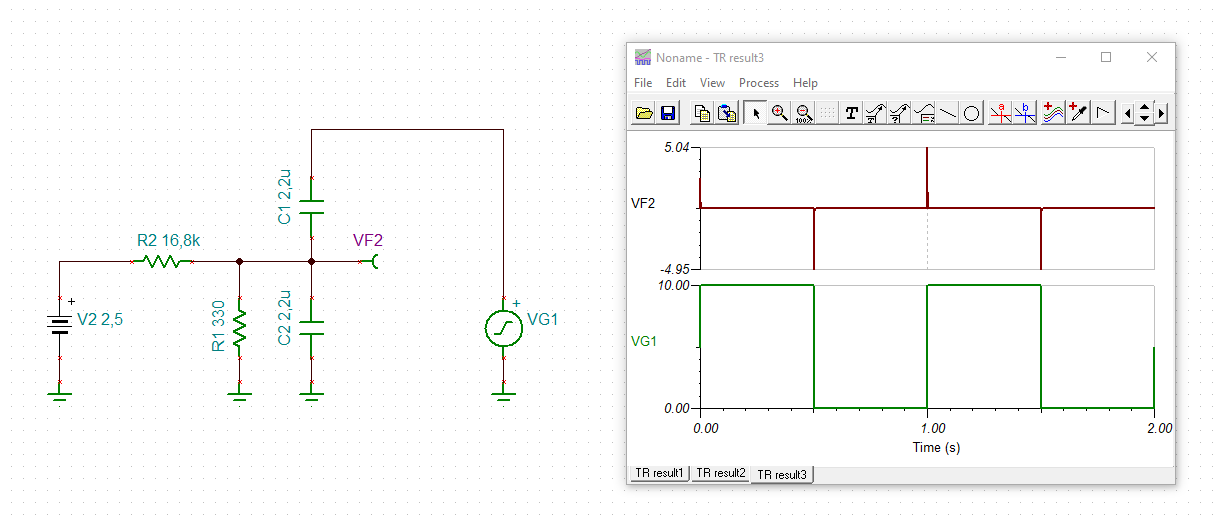

my customers used LM258 as a comparator in a product to compare the non-inverting input signal OUT- with the inverting input reference voltage LREF(The supply voltage on VCC is 10.6V). The product has shipped 260,000 units in batches. Recently, 28pcs failed products appeared. The specific problem was that PIN2 and PIN3 of LM258 were shorted to GND. The customer confirmed the problem by removing the chip and measure the impedance. Below is the schematic diagram and signals waveform. Please help to check whether there are design problems in the schematic. By the way, have you dealt with similar failure cases? Can you provide solutions or assist in failure analysis? Thanks!