Could you support to share the baking conditions regarding below for OPA2180IDGKR?

1, Which is the temperature condition that can be put to production in remaining in the state of reel under : (1) 120°C, (2) 90°C, and (3) 40°C?

2, Which conditions can the reel be removed and put to production in remaining in the state as a tape under: (1) 120°C, (2) 90°C, or (3) 40°C?

3, Could you explain what do the each temperatures for baking conditions these represent regarding (1) 120°C, (2) 90°C, and (3) 40°C regarding OPA2180IDGKR?

Device : OPA2180IDGKR

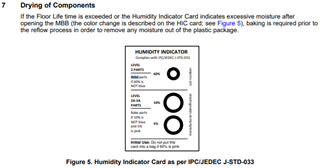

We have checked the AN-2029 Handling and Process Recommendations report which URL is below.