Other Parts Discussed in Thread: LM4120,

Hi,

I'm waiting for the PCBA of the design discussed in the thread:

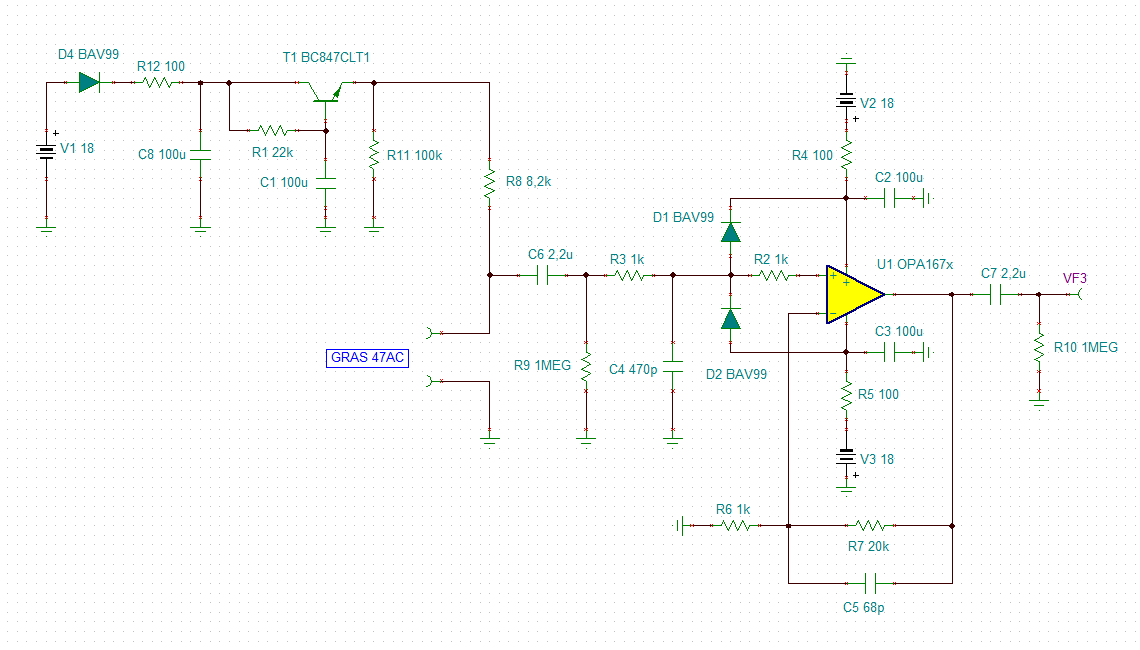

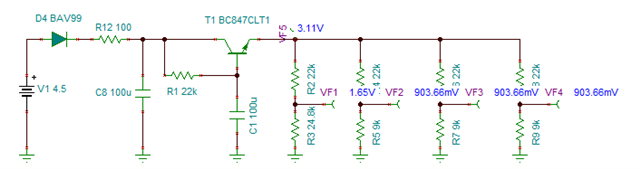

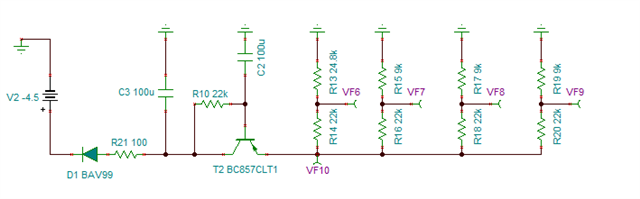

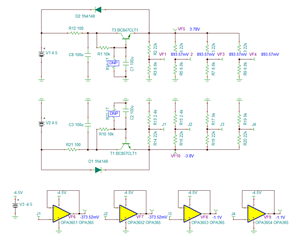

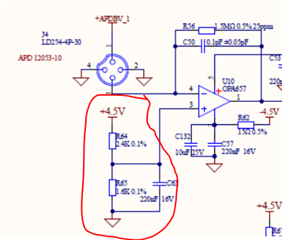

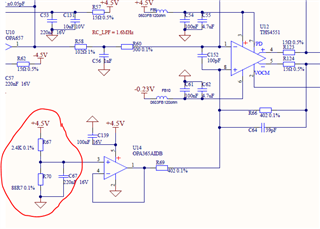

And I suddenly notice the bias reference for both TIA and FDA part:

It seems the filter consisting of voltage divider has very limited PSRR performance compared with the high PSRR of the OPAmps.

Is it a better idea to use low noise reference voltage source like LM4120 or other chips you would recommend to get best SNR performance?

Thanks!