LiDAR, Light Detection and Ranging, is an emerging technology to help advance the industry-wide movement towards autonomy and safety. To get up to speed on the architecture of these technologies and learn more about recommended devices such as the new specially designed transimpedance amplifier LMH34400, refer to TI application brief Time of Flight and LiDAR – Optical Front-End Design.

Many know Wall-E as the adorable robot from the 2008 Disney movie Wall-E. He has lots of interesting robotic features that allow him to come to life including cameras for eyes. But what if Wall-E wasn’t on an abandoned planet and instead was surrounded by unpredictable moving obstacles? Would his camera eyes be enough for him to navigate? In a present-day automotive vehicle, it is easy to understand why it would be beneficial to have all possible navigation methods available, not just cameras, to ensure the safety of the vehicle, passengers, and pedestrians. Using a suite of sensing modules, called a sensor fusion, allows navigation methods such as LiDAR, RADAR, and cameras to work in parallel for maximum distance and velocity measurements. It would also give the vehicle the best view into what obstacles could be in the environment surrounding the vehicle to give everyone peace of mind that autonomous vehicles are safe for all to enjoy. But is that same level of safety needed in a robot like Wall-E? If so, how does one get started on this type of design? To answer these questions, let’s give a little bit of background into what the difference is between automotive versus industrial LiDAR and why it is beneficial to have in your robotic design.

Automotive vs. industrial LiDAR

Automotive LiDAR can be most commonly found on commercial vehicles today in the shape of a medium sized puck on the top or side of the chassis, as demonstrated in Figure 1. These modules are often very complex, containing anywhere from 32 to 128 channels per module and move at extremely high speeds. LiDAR modules found in automotive vehicles typically feature an optical Time-of-Flight (ToF) architecture with an Analog to Digital Converter (ADC) based system, which allows each module to gain additional information per channel but at the cost of a higher power consumption and size. For additional details into the architecture types, including an ADC based system, refer to the TI App Note. Systems containing an ADC are often referred to as “3D” or “4D” designs, based on their ability to create a 3 or 4-dimensional point-cloud of information. All together, these features allow the technology to get a better idea of what is around the vehicle in real-time.

Figure 1: Automotive vehicle with mechanically scanning LiDAR module on the top, center of the chasses

Industrial LiDAR has the same technological fundamentals but often has fewer, or in some cases only one, channel per module. Additionally, many industrial LiDAR modules implement ToF architecture with a Time-to-Digital Converter (TDC) in replacement of an ADC resulting in fewer, more simplistic data points for a lower power solution. Because of the reduced complexity and size, industrial modules are often lower in both cost and power consumption while being easier to integrate into a robotic design. Some industrial modules do still use an ADC based architecture but reduce the number of channels, for a solution that balances the trade-offs mentioned above. Industrial LiDAR systems are most commonly placed in the “2D” or “1D” LiDAR category based on their ability to create a 2-dimensional point cloud or just a single dimensional distance measurement. A few industrial applications that are currently deploying industrial LiDAR are traffic monitoring systems, port and terminal monitoring, distribution warehouse navigation & monitoring, autonomous mobile robots (AMR), autonomous industrial vehicles (AGV), and even some personal electronic applications such as smartphones and tablets.

What benefit does industrial LiDAR add for robotics?

So now that there is an understanding on the difference between an automotive and industrial LiDAR unit, the question could be asked about why we might need a LiDAR module on an autonomous mobile robot (AMR)? Why are cameras not enough? Robots are being designed to go new places and move more independently than ever. Imagine an AMR delivery unit is moving down a sidewalk in a neighborhood. There are houses up and down the street, with many day-to-day challenges such as cars, garbage bins, pedestrians, bikes, children’s toys, and more. These are just a few of the many outside factors that could impact the robot’s ability to complete its set mission both from a distant or suddenly. It is important for the AMR to detect those obstacles, assess their potential impact, and react accordingly all in real-time for the safety of the community. The use of LiDAR ensures that if a ball rolls onto the sidewalk, quickly cutting off the path of the robot, it has the necessary resolution and time response to sense the environmental change and react quickly to avoid collision and damage. Cameras can provide a high-resolution image however they have poor distance measurements which is an important factor in deciding if a robot can keep moving or if there is an obstacle and needs to redirect.

Figure 2: Autonomous mobile robot (AMR) featuring a mechanically scanning LiDAR module on the top, rear side of the unit

Additionally, we want our robot to be able to work in all lighting conditions, such as a cloudy day or at night. LiDAR is not limited by lighting conditions nor does it require external illumination, a primary limitation to camera-based systems. This will allow the robot to perform well at all hours whether in broad daylight or under the cover of darkness.

How do I get started?

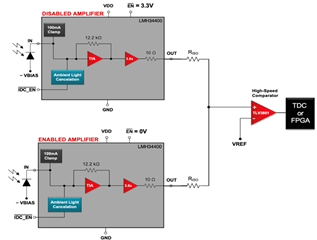

We understand now why LiDAR is advantageous for a robotic unit. How do I get started with my own development? TI is the leader in integrated current-to-voltage transimpedance amplifiers (TIA) that are critical building blocks in the receiver analog front-end design of a LiDAR system. The LMH34400 features a single-ended output which is perfect for a TDC based design and includes unique features to ensure the safety of the device and enhance sensitivity performance. This device will allow you to implement a single chip solution between your photodiode and TDC, or it can be paired with a high-speed comparator such as the TLV3801 for an even sharper signal rise time.

The LMH34400 also contains a suite of integrated components to decrease parasitic capacitances, overall size and complexity of the system. For example, a 100 mA protection clamp has been designed to protect the amplifier and help it recover quickly from an overloaded input condition. Remember our scenario where a ball rolls out right in front of the robot? This clamp will help ensure that the system is able to recover quickly from that potentially sharp input spike based on the sudden short-range object detection with minimal down time. Additional integrated features on the LMH34400 include a 40k-Ohm transimpedance gain to remove the need for external passives and making it easier to stabilize than with a discrete resistor, ambient light cancellation (ALC) circuitry to filter out residual background level light that would normally impact the dynamic range of the receiver, and a power-down mode that will allow the device to be used in multi-channel systems without the need for an additional discrete multiplexer (Figure 3). All of this has been put in an ultra-small 5-pin SOT-5X3 package measuring only 1.60 mm × 1.20 mm, making it perfect for space constrained and cost sensitive projects such as an AMR.

Figure 3: LMH34400 in a 2-channel multiplex configuration with an optional comparator into a TDC

Conclusion

LiDAR is a critical part of the path towards mobile autonomy in both automotive and industrial vehicles. It provides the systems with key functionality such as object detection and collision avoidance in real-time, to help ensure the safety of the surrounding environment and vehicle. To get started on your LiDAR design today, take a look at TI’s integrated transimpedance amplifiers, talk to your local TI sales representative to learn more, or comment below to get a conversation started.

Additional Design Resources:

- Time of Flight and LIDAR - Optical Front-End Design

- Maximizing transimpedance bandwidth for LIDAR and time-of-flight (ToF) applications

- LiDAR Pulsed Time-of-Flight Reference Design Overview

- An Introduction to Automotive LiDAR

- Application Guide - Industrial Mobile Robot

- Questions? Talk to an expert by commenting below!