Hi,

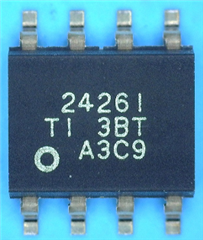

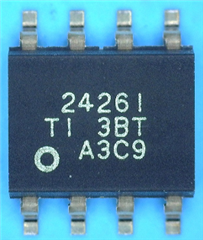

We buy some TLE2426IDR from mouser, they're came in with different level of scratches and copper exposure was found on all samplings.

Mouser suggest us to contact you with TI FAE directly. do you know what's the reason? thank you.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

We buy some TLE2426IDR from mouser, they're came in with different level of scratches and copper exposure was found on all samplings.

Mouser suggest us to contact you with TI FAE directly. do you know what's the reason? thank you.

Hi Heidi,

These are testing markings from the IC's screening process, where each IC is gone through a defined testing sequences. If the ICs are evaluated and met the screened datasheet specification, then there parts are packaged at the end of ATE production line. These markings are normal and do not affect the functionality of the parts.

Please give me a couple days and I will see if we have a standard or the cosmetics appearance of the delivered products. The middle image is magnified by 6X-8X and so it will look "scratched" from the image. I will see if we have a standard quality control about these markings. If so, how these markings are defined as the acceptable "scratches" of the deliverable goods. .

Best,

Raymond

Please give me a couple days

Thank you Raymond, if you have Formal documentation will be appreciated ~

Hi Heidi,

I have received the reply back from our manufacturing Quality engineer - The "scratched" markings are generated from ATE testing process(Different socket pin will generate different scratch mark). From below snapshot view point, that’s belong typically mark and within Spec(QSS-005-105).

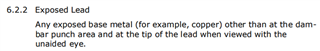

QSS-005-105 V/M Quality of Finished Product (Dual Inline Lead Surface Mount Packages)

https://giant.sc.ti.com/SCQS/qssrep.nsf/active/005-105.pdf/$File/005-105.pdf?OpenElement

My comments. Copper based alloy leads are scratch-prone metal conductor. If the product has solderability issues, we can contact the quality engineers.

If you have further questions, please let me know.

Best,

Raymond

Hi Raymond, I can't visit this link https://giant.sc.ti.com/SCQS/qssrep.nsf/active/005-105.pdf/$File/005-105.pdf?OpenElement how to get this PDF?

Hi Heidi,

The information is not public, which I did not realize that.

I will send a "friendship" invite to you via E2E private messaging system. I will send you the document once we established the contact.

Best,

Raymond