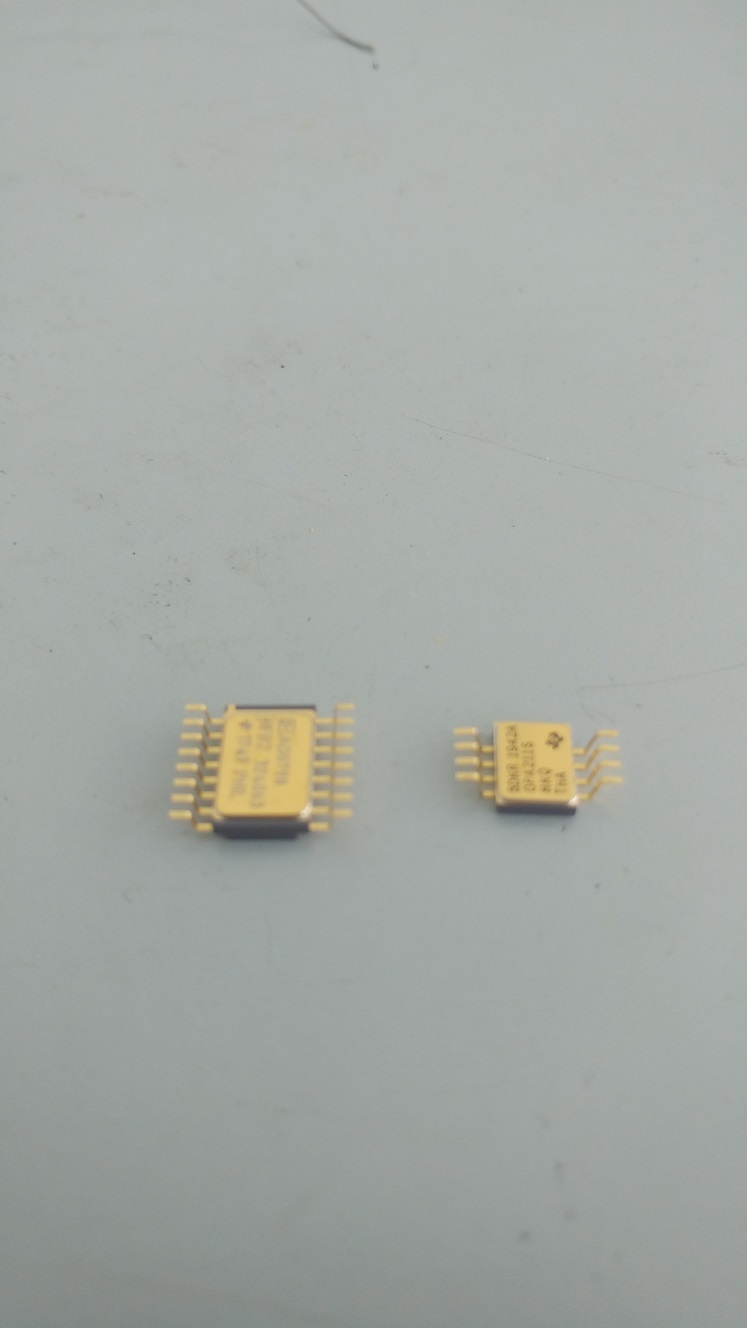

We are using your 200 °C integrated components with HKQ case(OPA211SHKQ). These components have a space of 1 / 1.3mm in the part below in contact with the PCB.Does this space need to be filled with a resin to firmly fix the components? The PCB must be mounted in an oil well and must withstand high vibrations. Is it correct to do this type of assembly? The gold pad or lid does not need to be soldered to the board, but with the 1 / 1.3mm gap only soldered by the pins and locked with the thermal resin, is that correct? What do you recommend? We have already purchased components from Mouser. Attached photo of IC.

Thanks

Antonio