Hello,

How to wash the circuit board of the transimpedance amplifier on the LMC6001 chip after soldering?

Especially interesting the input circuit at the place of mounted installation and the body of chip.

PCB material - FR4.

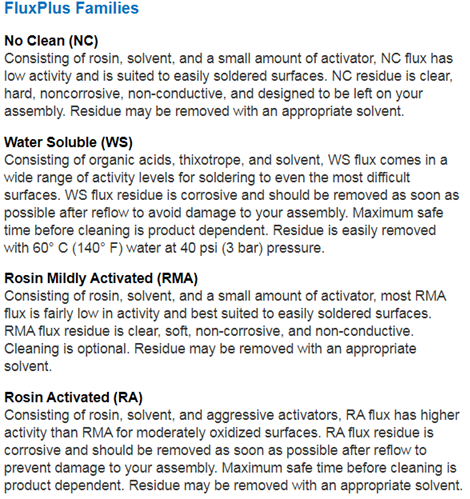

Flux for soldering - BGA Flux Plus 7019074 Nordson.

Is isopropanol OK?

Regards, Andrey