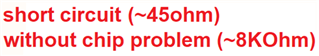

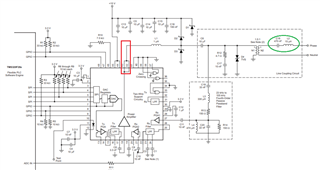

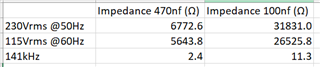

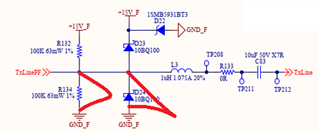

Dear Texas, we have a serious problem on several PLC chips (AFE031) after a few months of normal operation. Sometimes the transmitting stage doesn't work but only the receiving one, sometimes the whole chip. The problem would seem to be located on the outputs of the amplifier set from Rset to 1.6A (see schematic and burned chip photo attached). Please let us know as soon as possible if we have made any mistakes on the conditioning circuits or we need to reduce the transmit power output from the PA to solve the problem.

Best regards

Andrea vinci