Dear TI audio IC designers,

We need in TPA6120 headphone amplifier additional information:

There is power supply capacitance of low ESR 100uF electrolytic on each rail at the TPA6120A2 headphone amplifier datasheet application circuit.

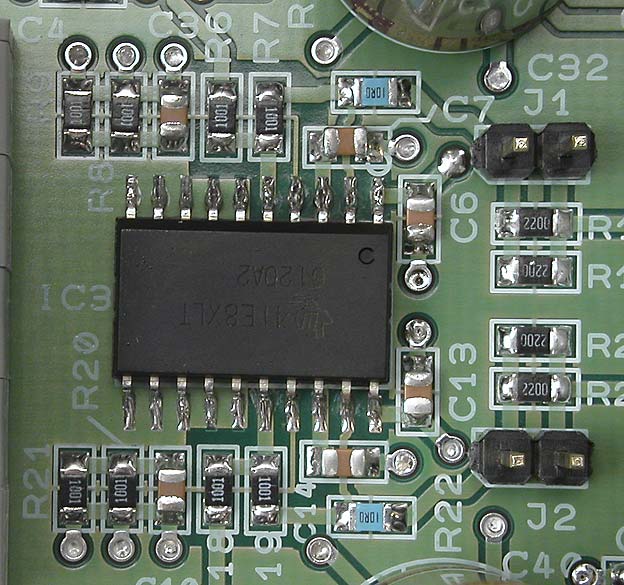

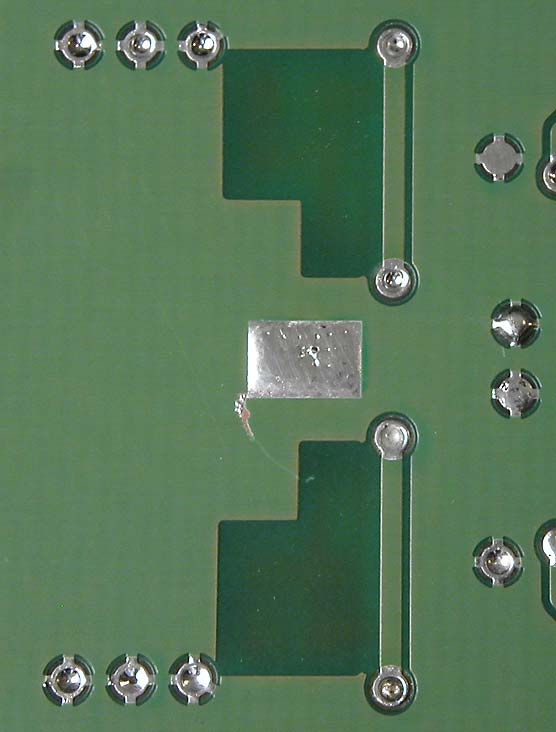

There are such power supply capacitors on the TPA6120A2 Evaluation Module schematic (slou169 document).

Unfortunately, the TPA6120A2 Evaluation Module user’s guide has no information regarding its real THD specification.

Is it enough the TPA6120A2 power supply capacitance of those low ESR 100uF on each rail to keep the headphone amplifier THD value (in full sound bandwidth range) at the datasheet listed level and load resistance of 70..300 Ohms?

The TI audio forum (in the Audio FAQs ) has some considerations on this subject:

***********************************************

How can I improve low frequency THD+N in my design?

If you changed PVDD capacitance, you can see increase THD+N at low frequency input case and also this value depends on channel separation factors. If someone would like cost reduction by decreasing PVDD cap value and size, should check low frequency vs THD+N spec before changing capacitance.

http://community.ti.com/forums/t/2645.aspx

***********************************************

Sincerely,

Alexander M.