Hello,

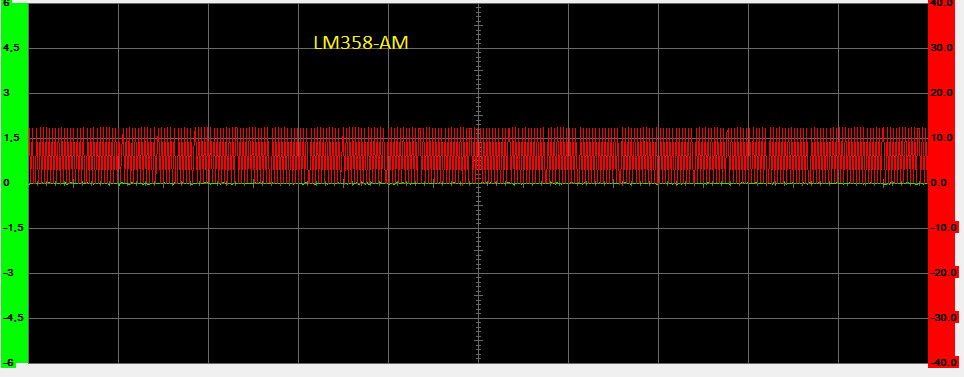

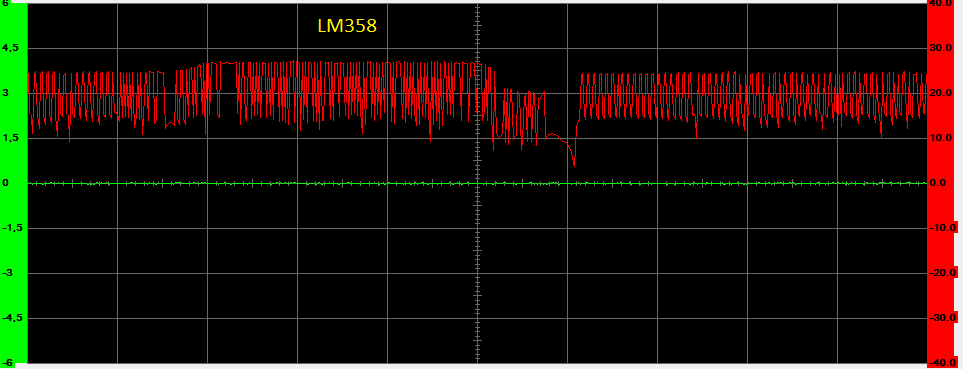

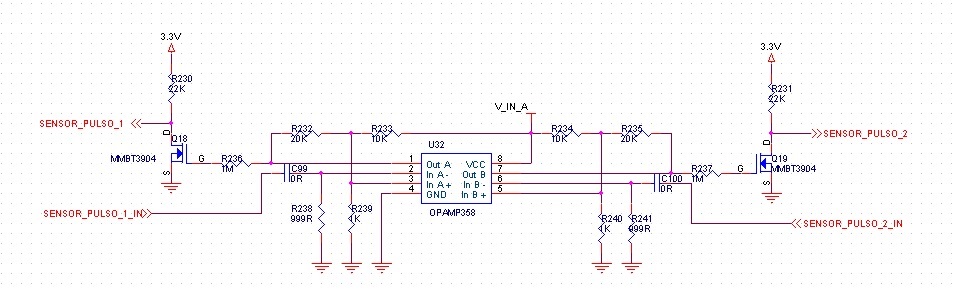

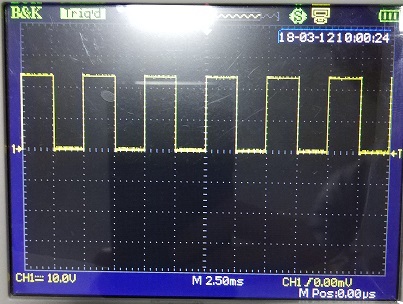

I use the LM358AM to measure RPM in a vehicle. I change the LM358AM to LM-358 and LM-358E. This new amplifiers burnt and stop work.

What´s the difference between this part numbers? Have some significative information thtat i didin´t seen?

Thanks and best regards