Other Parts Discussed in Thread: STRIKE, TLC272, TLC277, TPD2E007

Hello,

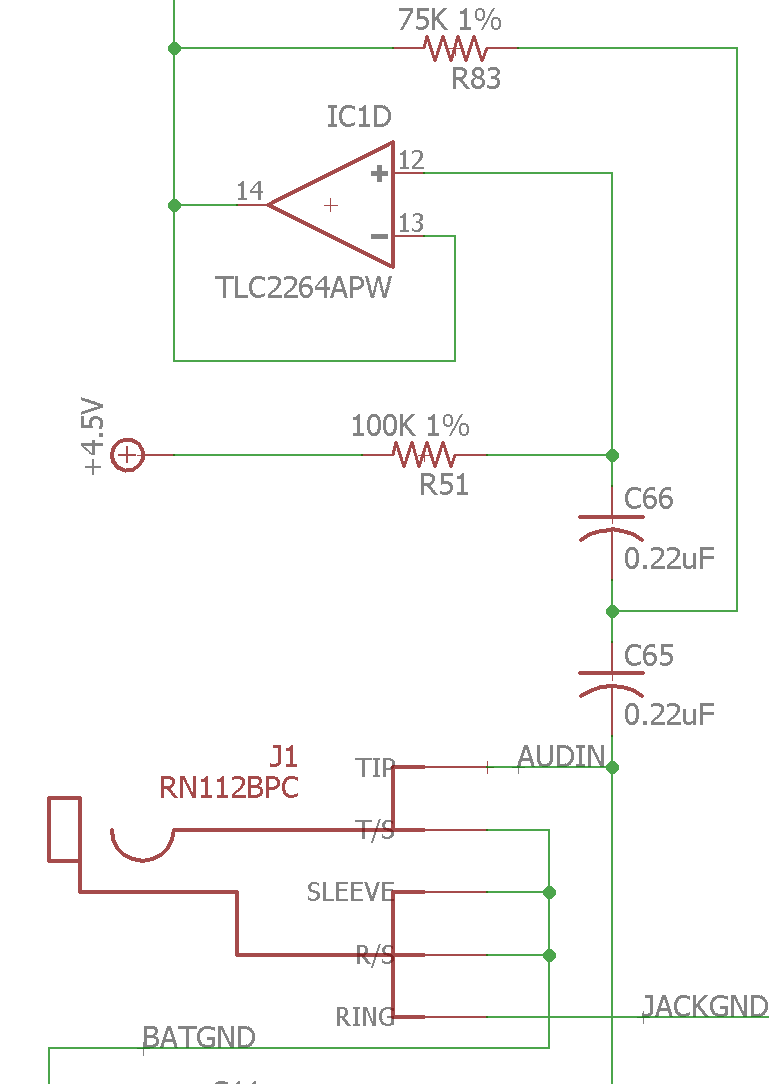

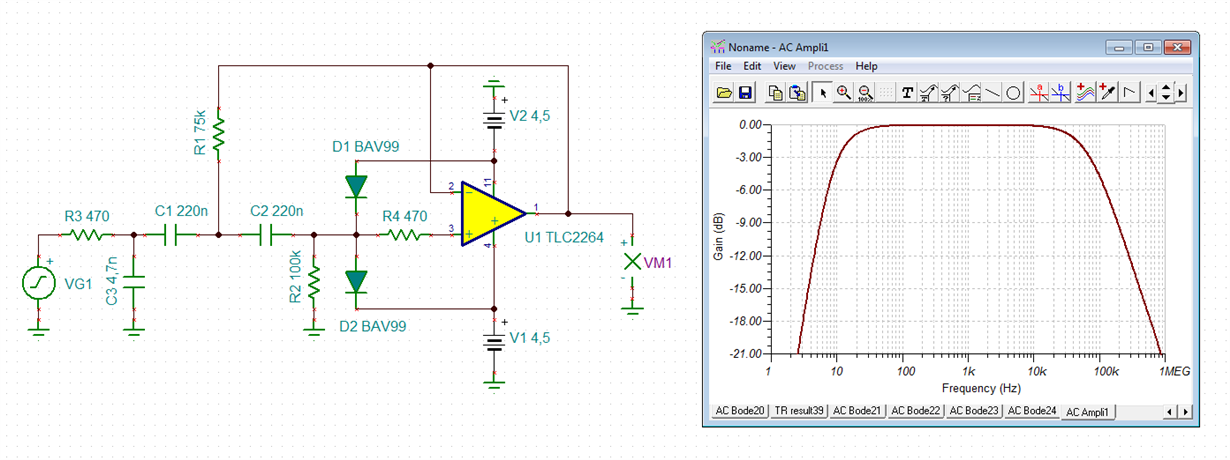

I'm having a problem where a TLC2264APW chip is repeatedly getting damaged in my circuit. One op amp in the quad package is connected as a Sallen-Key high-pass filter with cutoff around 10Hz. The portion of the circuit touching my input looks like this:

The symptom is that the op amp ends up drawing way more current than it should (>100mA). Fortunately it's powered from a voltage regulator with current limit and it brings the whole supply down without causing more damage. However, the TLC2264 package in question gets very hot to the touch, which proves to me that it is the source of the problem.

My worry is that an instrument cable can be plugged directly into the 1/4" instrument jack -- then the tip connection of the cable will be capacitively coupled (via those two 0.22uF caps in series) directly to the op amp input. Is it possible that ESD events on the cable tip (when a person touches the tip for example) could zap the TLC2264, causing the symptoms I've quoted above? Is there anything I can measure to determine if indeed the damage is caused by an ESD event?

Finally, if the failures are indeed caused by ESD can you recommend a solution to prevent them in the future?

Thanks!

-Brian Kaczynski