Other Parts Discussed in Thread: LM317, TLV4172

Hi

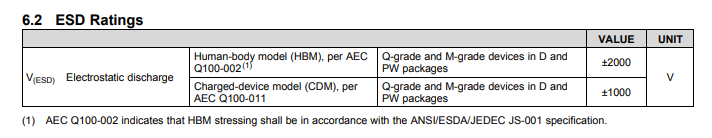

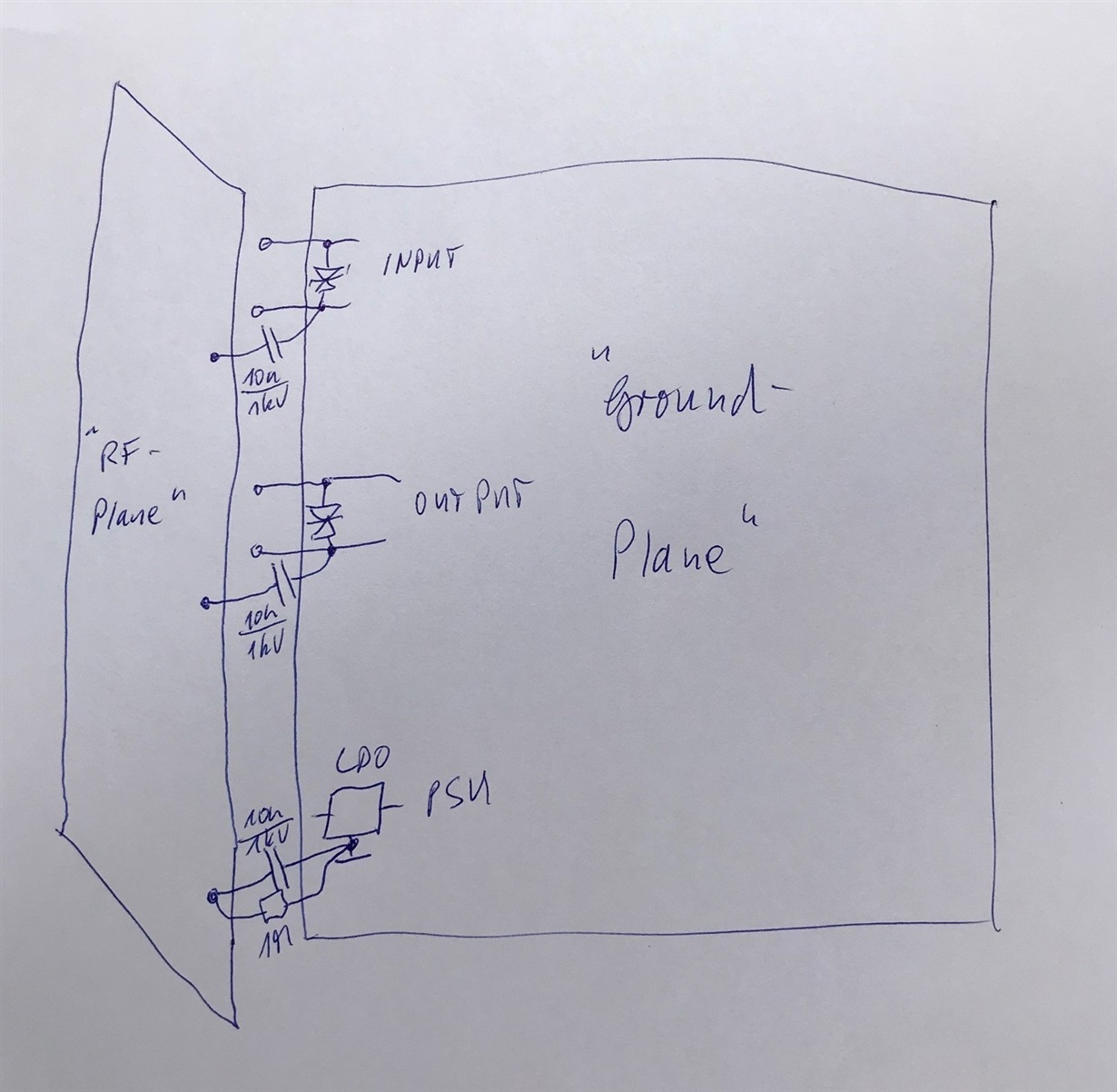

Have an ESD issue here.

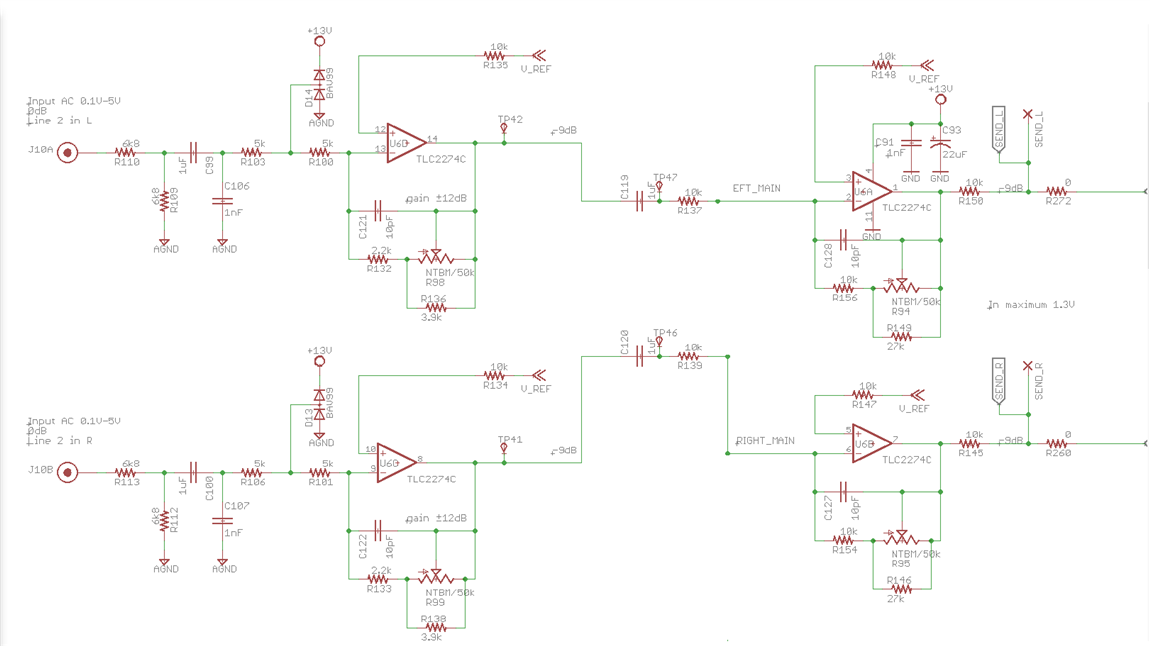

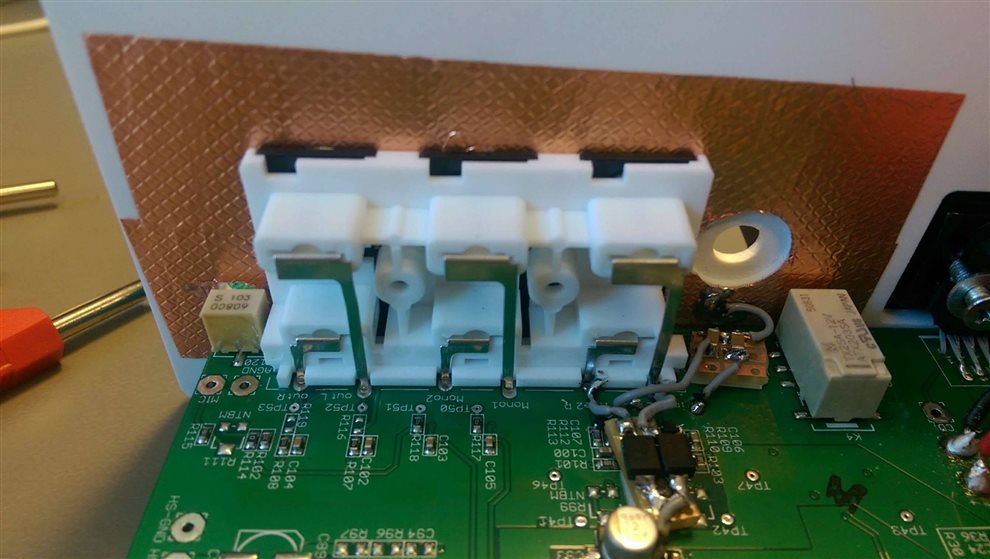

I'm using TLC2274 quad SSOP package. There is no internal clamping diodes for protecting inputs. I'm hoping there is a replacement with input protection?

There are 2 diodes for transient suppression on Vin- but this is not enouf for making is pass ESD.

Looking for any solution that helps me pass ESD... replacements of opAmp(military version of TLC2274?), suppression diodes or schematic mods.