Other Parts Discussed in Thread: OPA627, THS4531A, NE5534A, NE5534, LM317

Hello

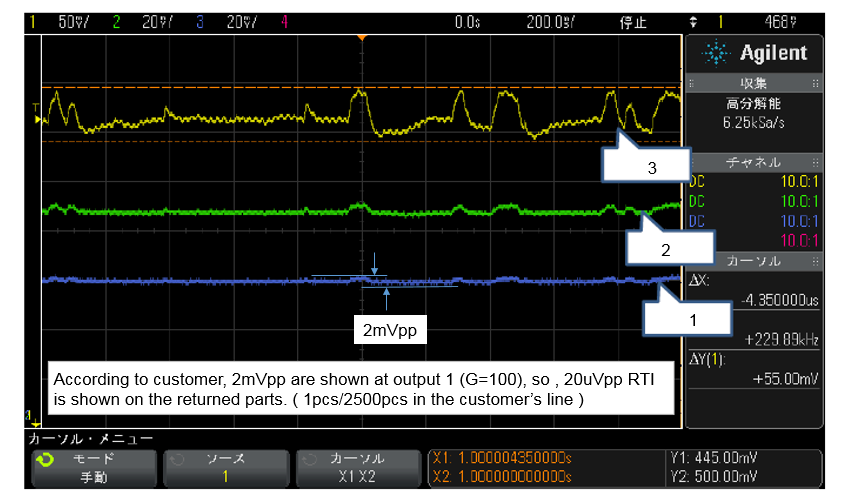

My customer had chosen INA126 for their product ( Flow-meter) but they found noise issue for 1pcs of 2500 pcs in their production line.

Where: Vs= +/- 15V , G=100

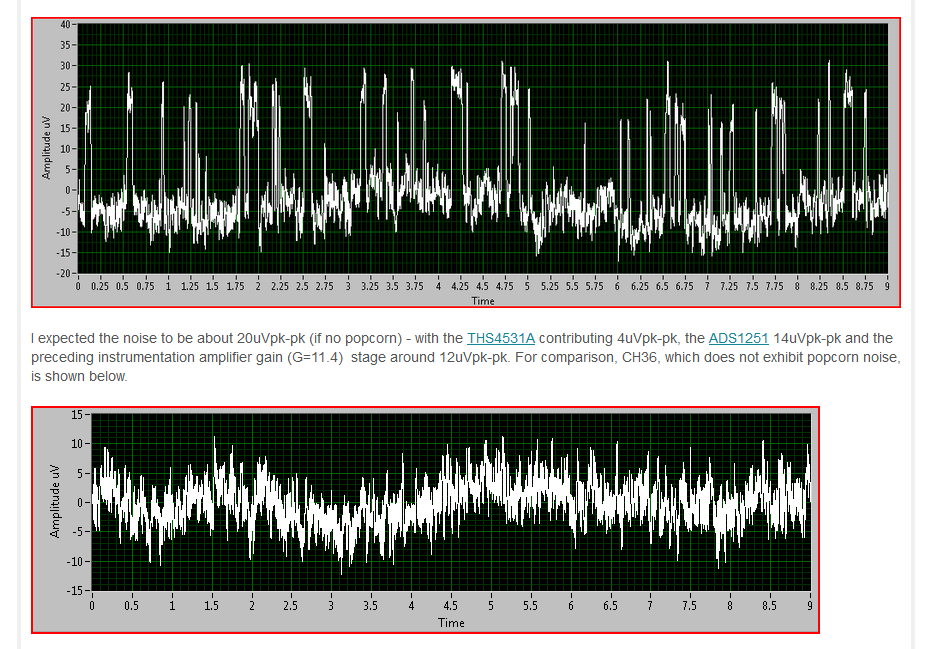

Noise ( 1/f noise ) 20uVpp RTI found.( wave form attached).

When they replace it to new( good) INA126, phenomenon had fixed.

Q1

Do you think this phenomenon is normal? ( In the data sheet,

noise voltage RTI is 0.2uVpp (TYP), but (max) is not defined)

However, I think this is abnormal and it should be QA issue.

How do you think?

Q2

This noise is 1/f noise and popcorn noise ? Please kindly check the waveform.

If not popcorn noise, please advise about what is the cause of this noise.

Thank you for your cooperation.

Best Regards