Other Parts Discussed in Thread: TINA-TI

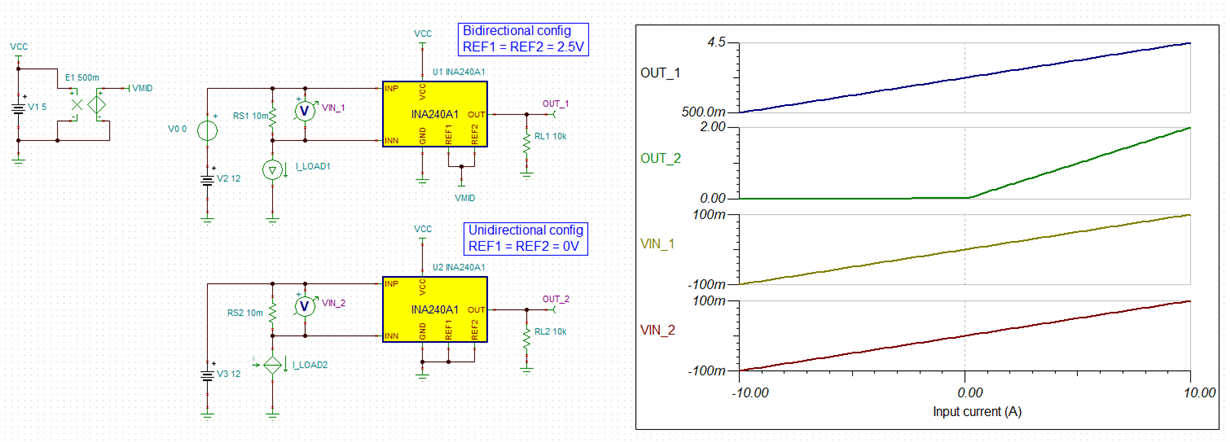

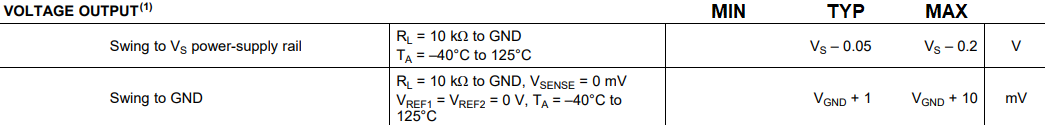

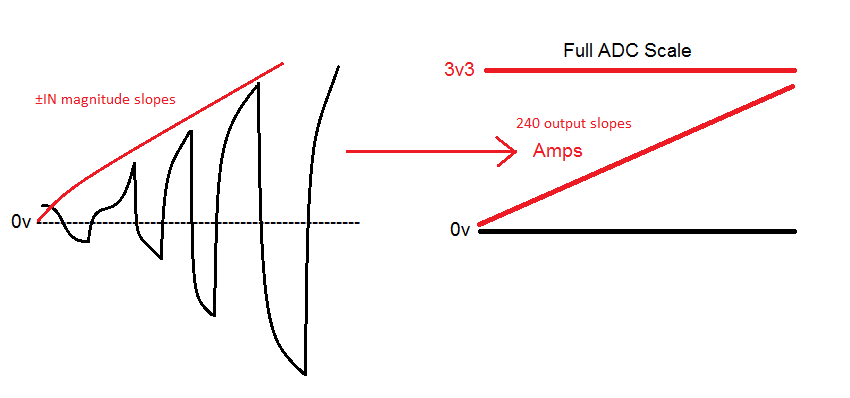

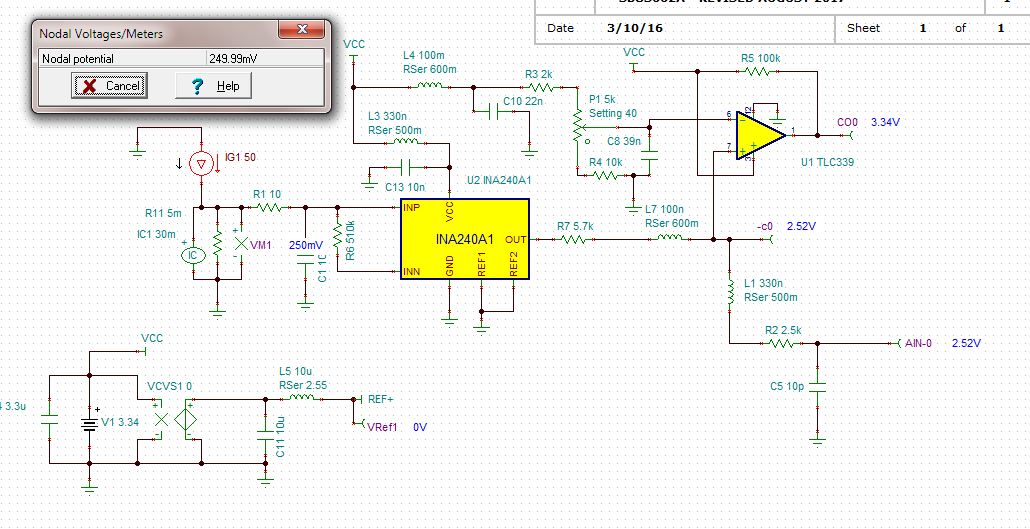

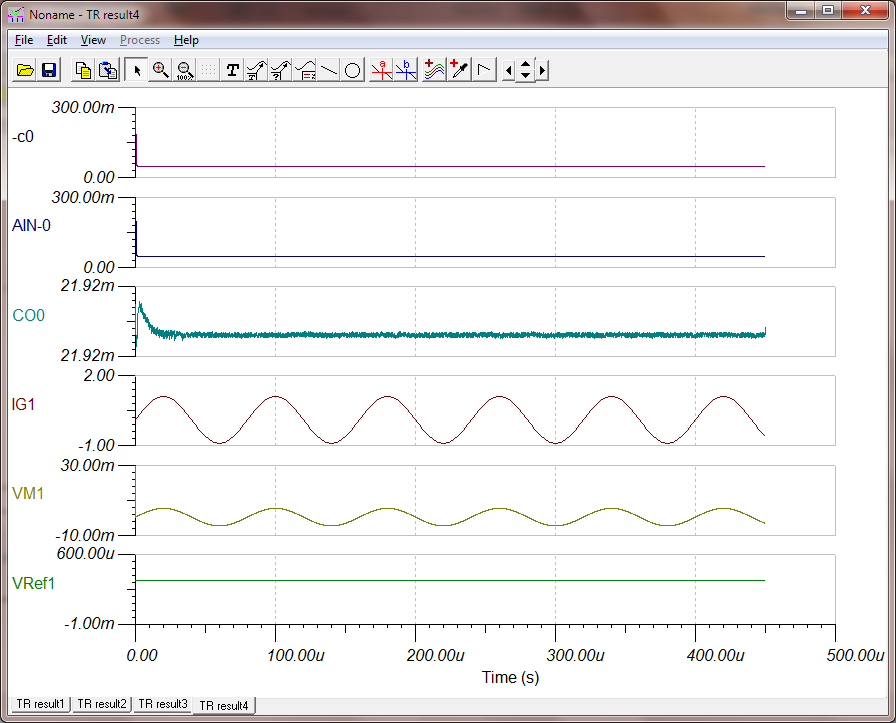

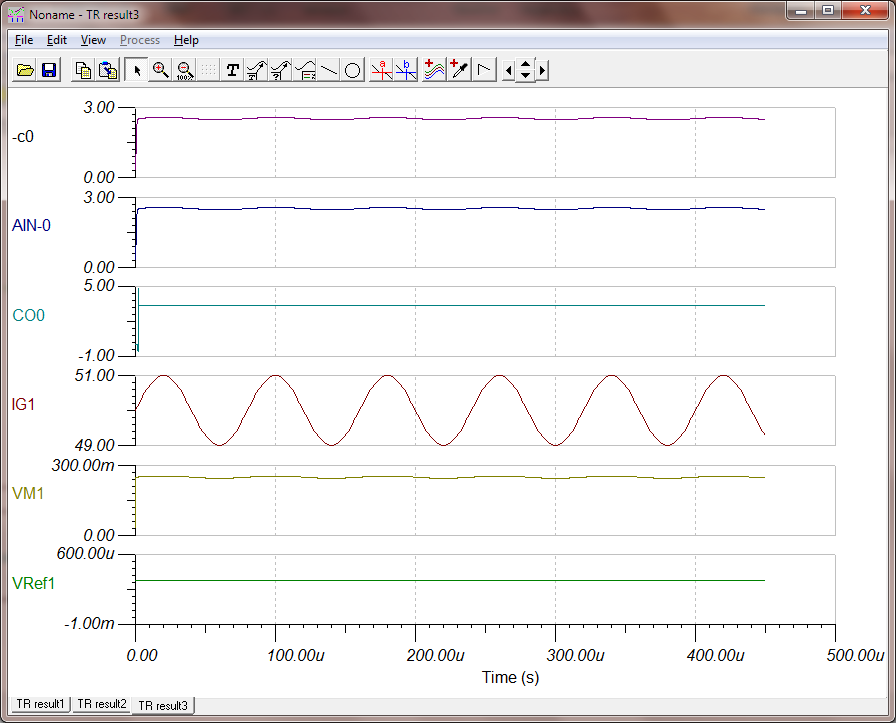

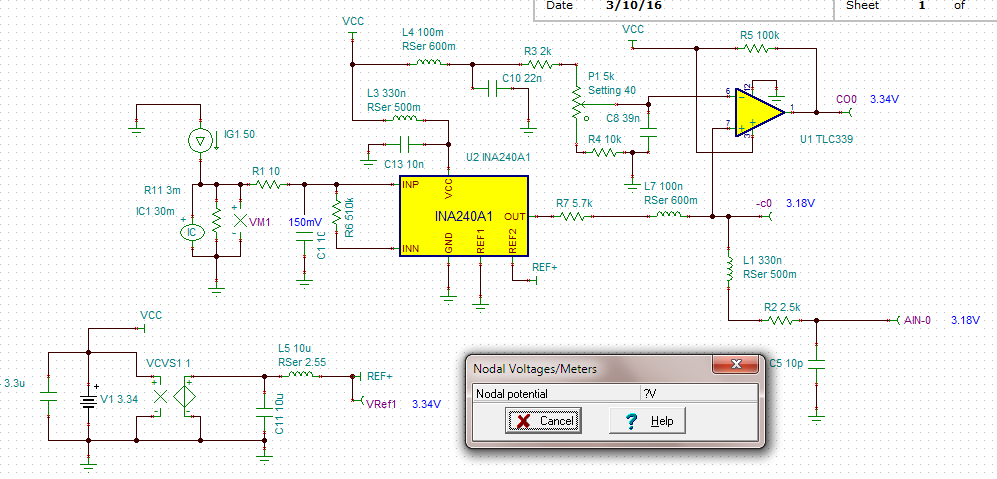

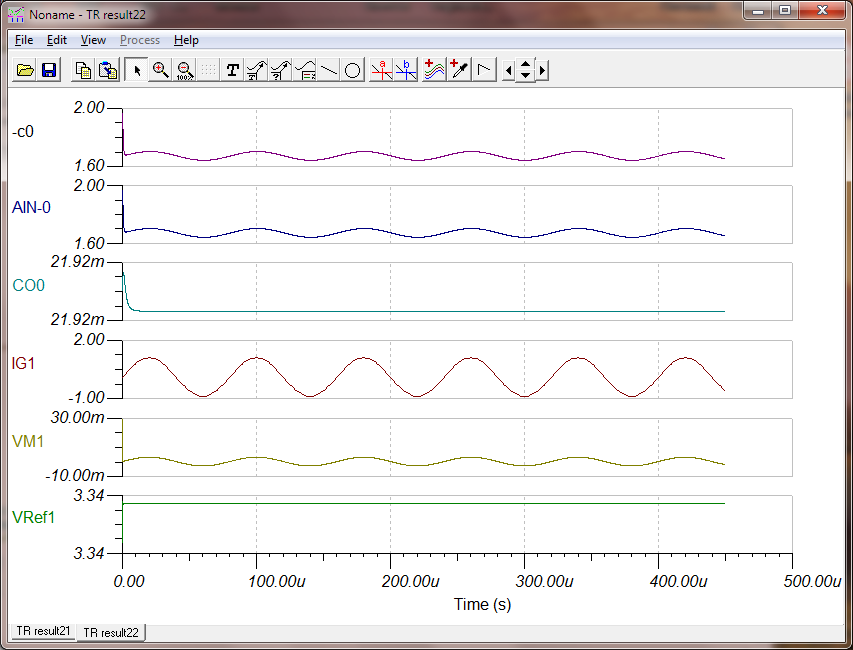

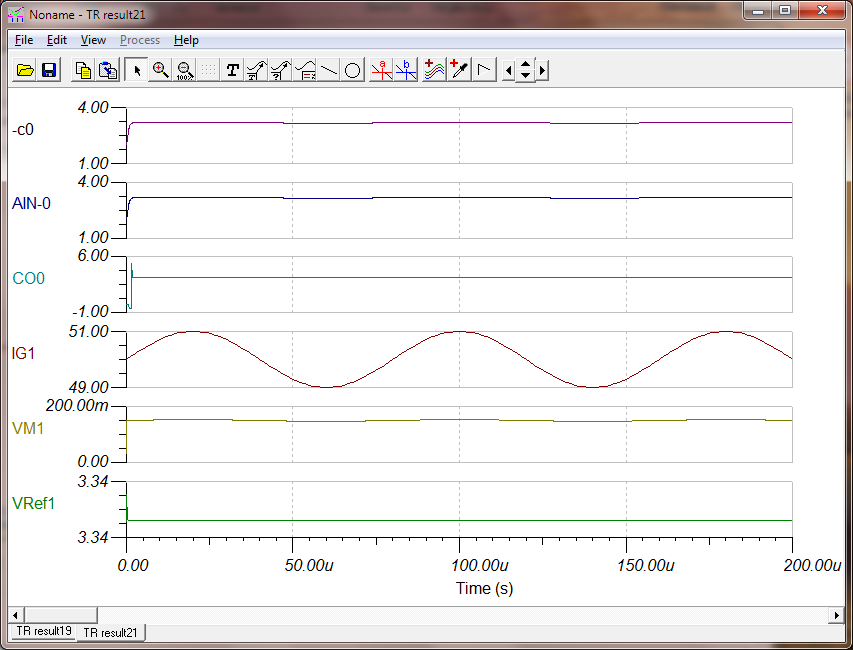

Recently tested a competitions Hall type monitor forced mid supply (1.65v) by design, It only worked well at 24vdc inverter power otherwise tripped comparator faults at higher voltages. One reason we set 240 single ended uni-direction REF was due to frequent faulting at mid supply. It seems unidirectional ADC samples can only detect the negative bipolar inerter current after 240µs delay in Nyquist frequency. So it seems an added delay is required for ADC samples to hold off during the transition for the missing positive shunt data (CH1 below ground) into the negative 240 output on top CH2. From the ADC perspective of triggered samples, the positive current data is missing that was generated by the PWM and synchronized via the sample event blanking timer.

That is not so obvious bidirectional does not work properly with single ended ADC channels. Other competition datasheets are very specific, bidirectional current monitor requires differential ADC channels to capture the samples.

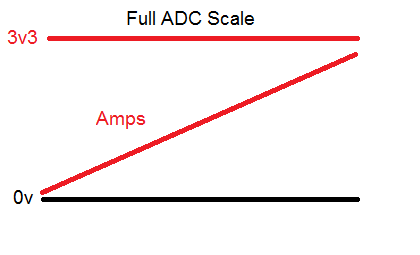

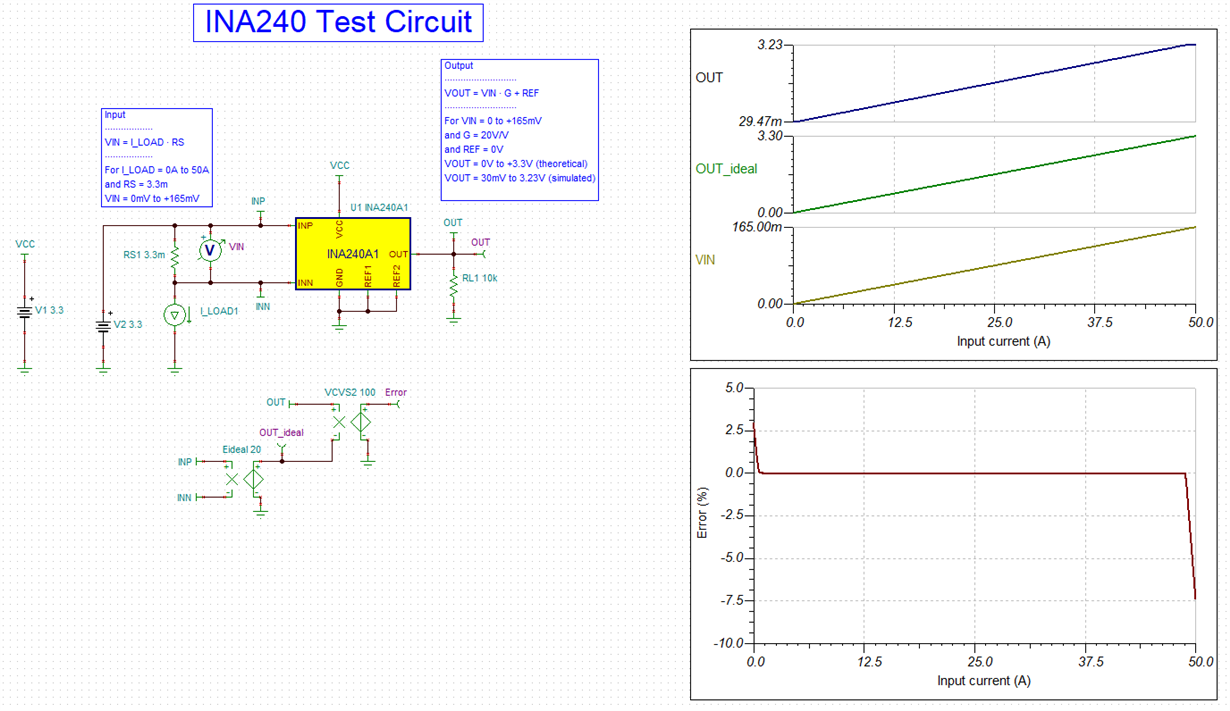

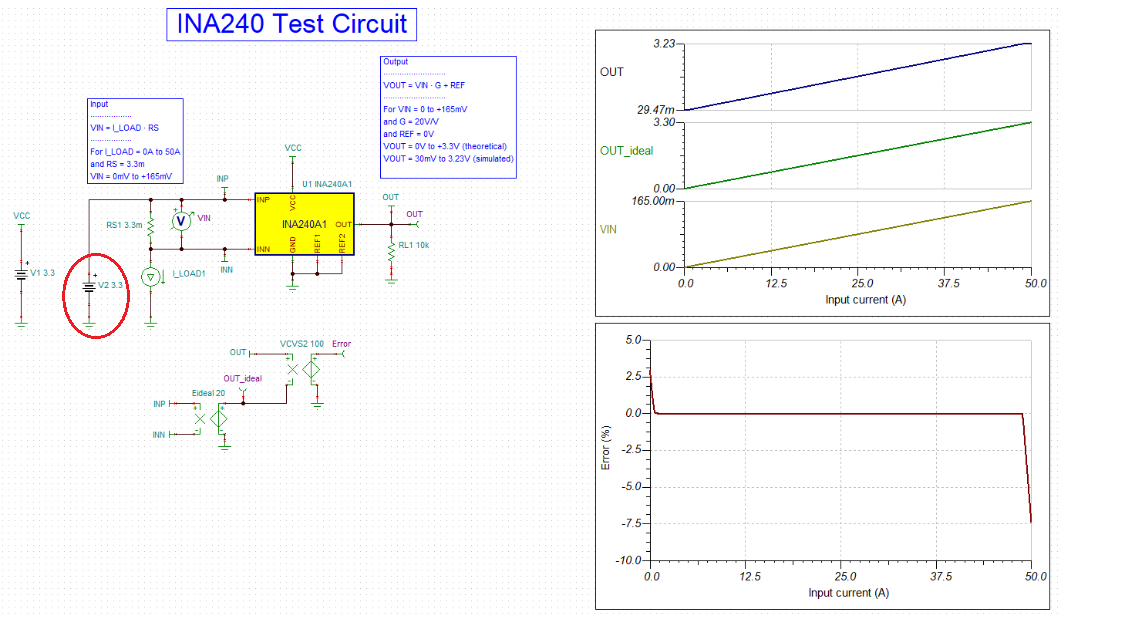

Are we stuck with single ended ADC unidirectional Negative current samples? Why does the 240 not capture both sides of shunt data, omits positive cycles when single ended supply differential amplifier is considered bipolar? Is there a way to tick the differential amplifier to produce both sides with an output from 0v up to rail? Does 240 require a split supply to produce ratiometric bipolar output from ground up? Perhaps another INA series makes a better choice for SAR ADC single ended channels?

Below 16x average samples of CH2 reveal CH1 positive shunt data is not even included in the CH2 output. Note the 240us delay for the ADC to skip the missing positive PWM cycles below ground, zero crossing events.