Other Parts Discussed in Thread: TINA-TI

Hello, I was hoping to get some help on a simple design.

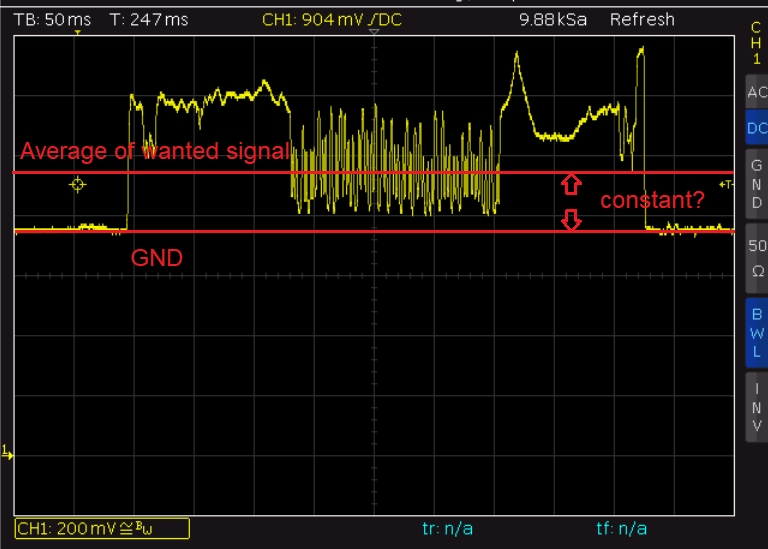

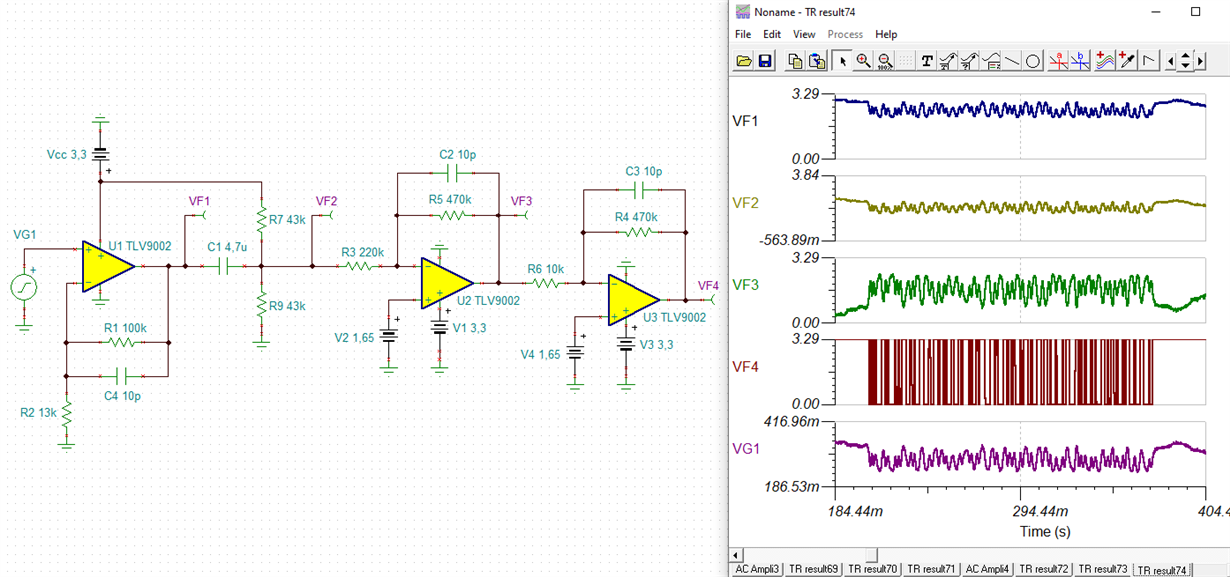

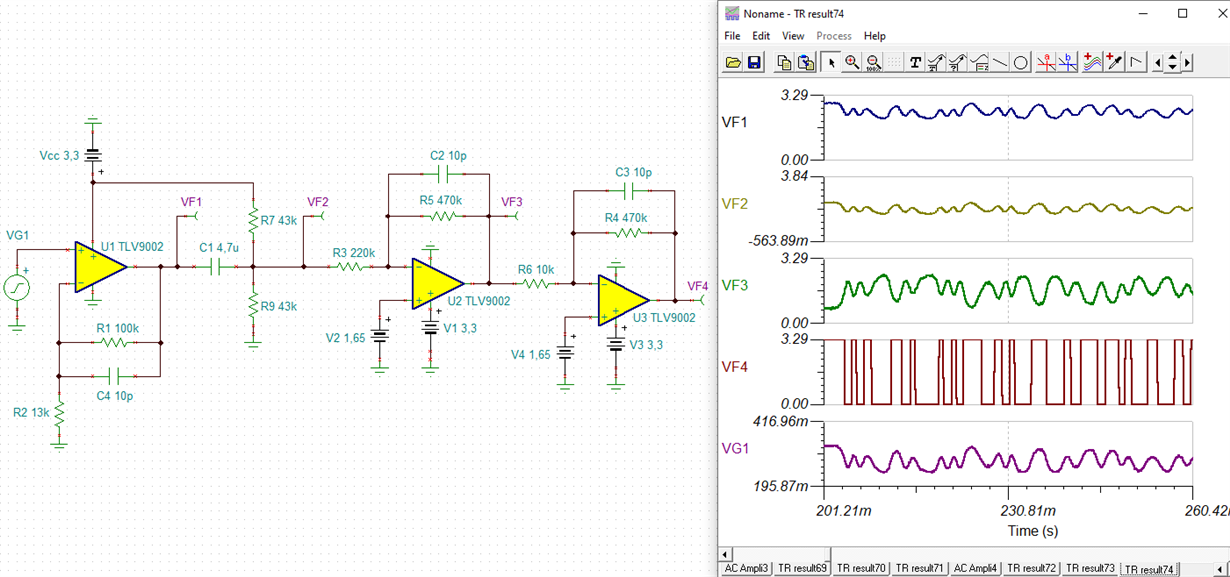

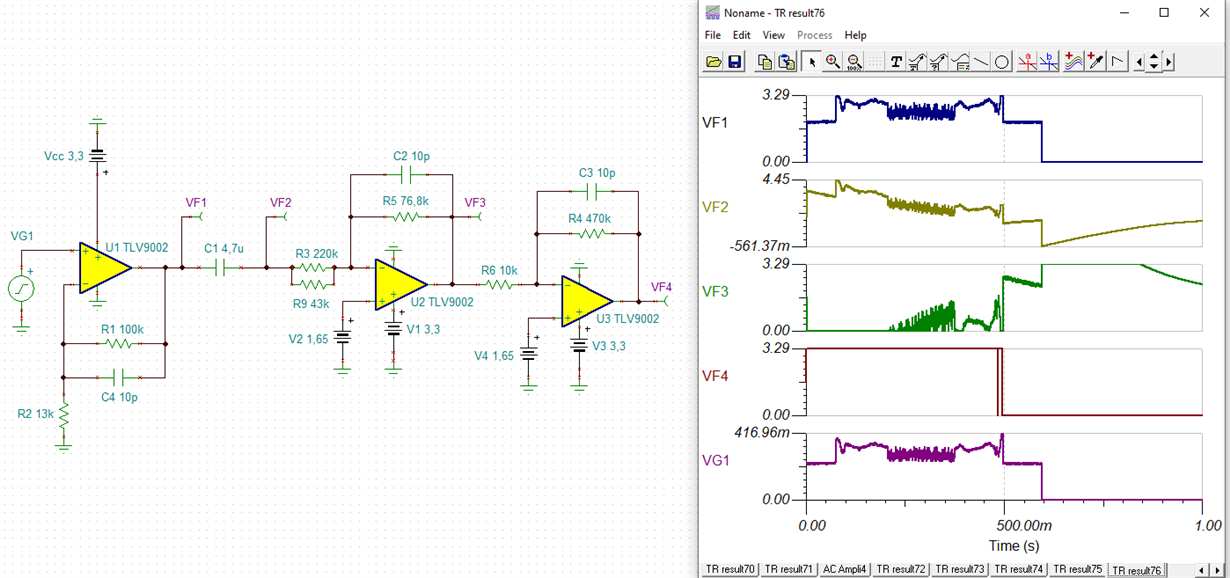

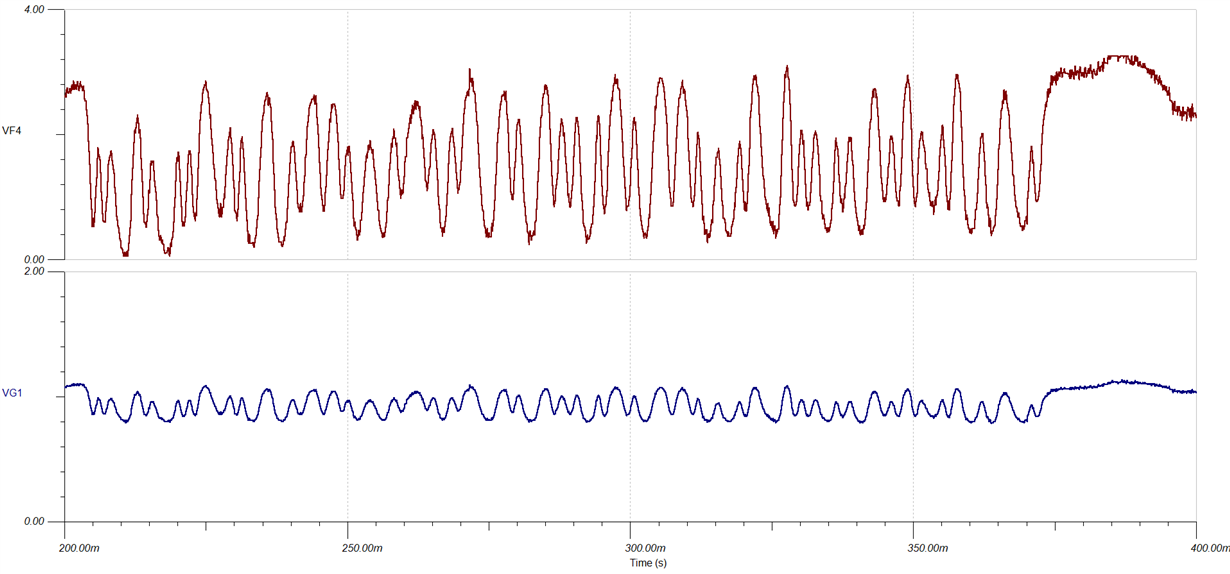

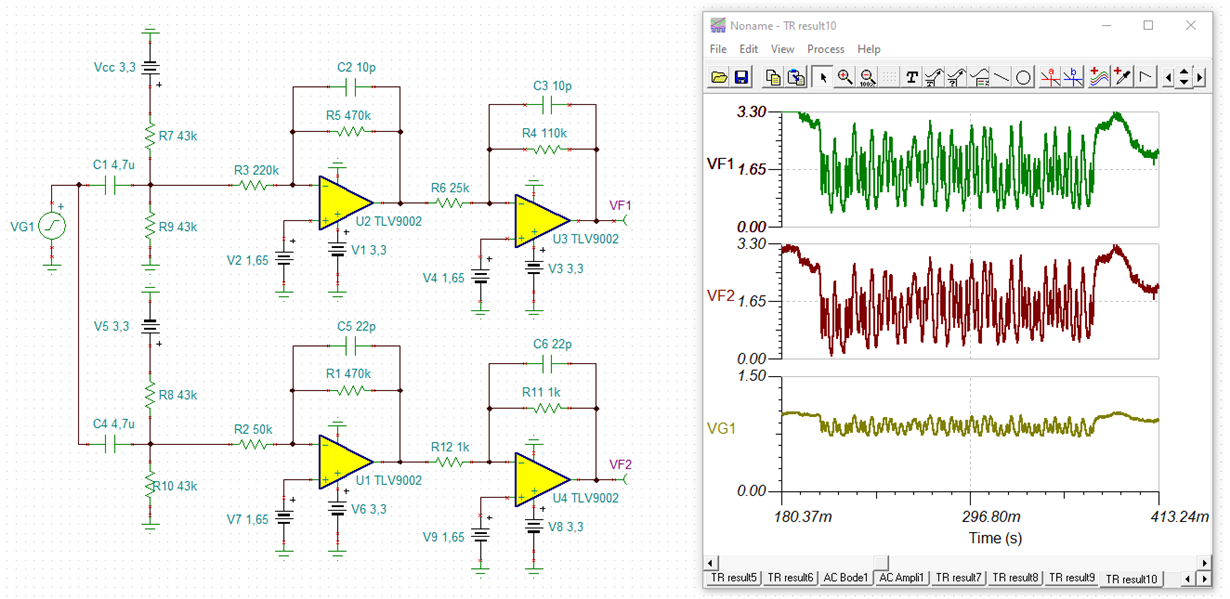

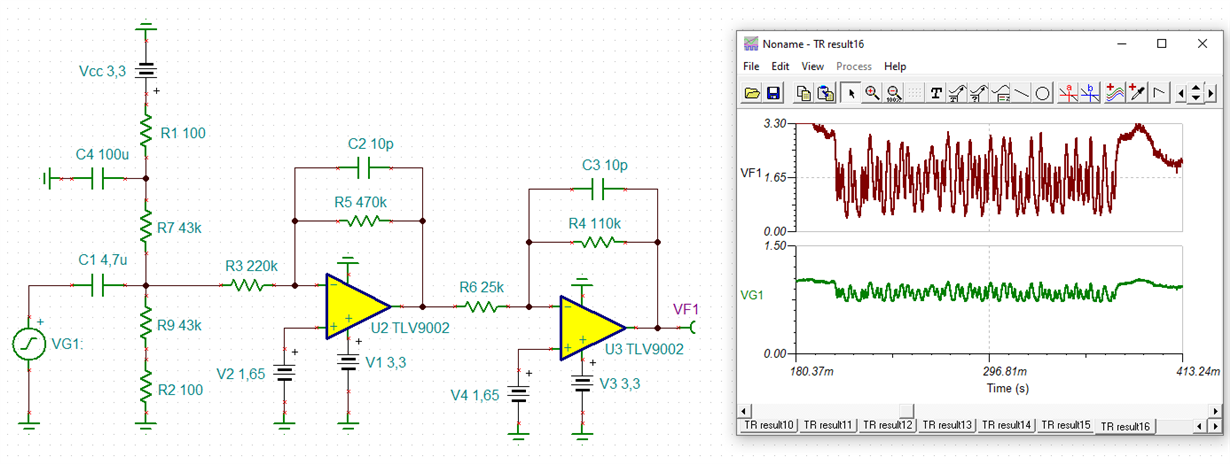

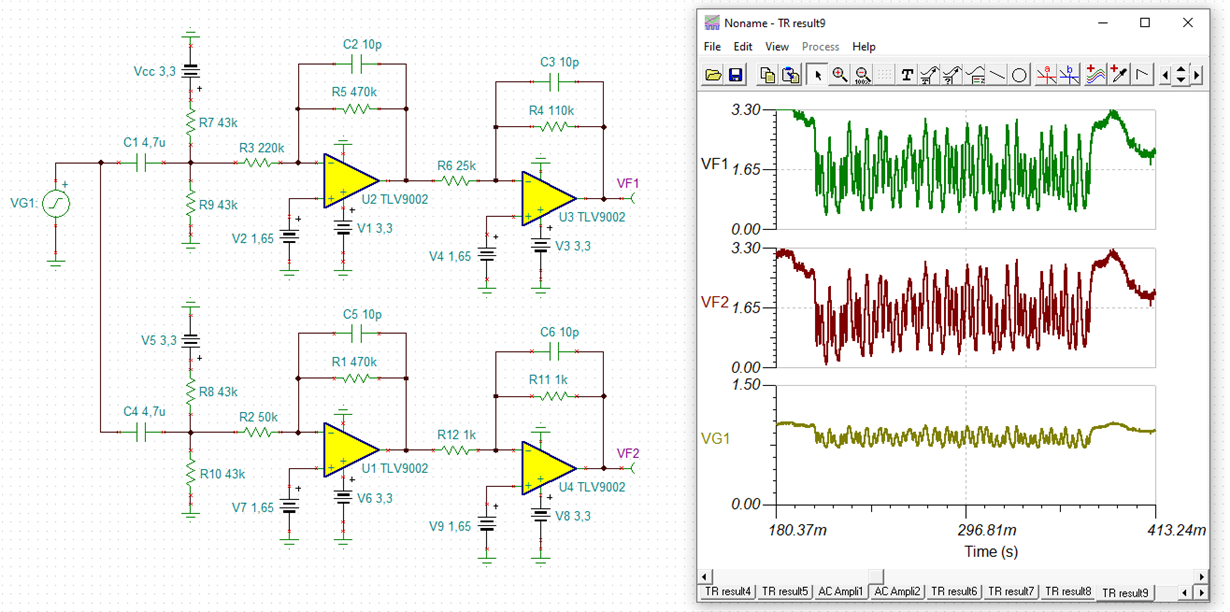

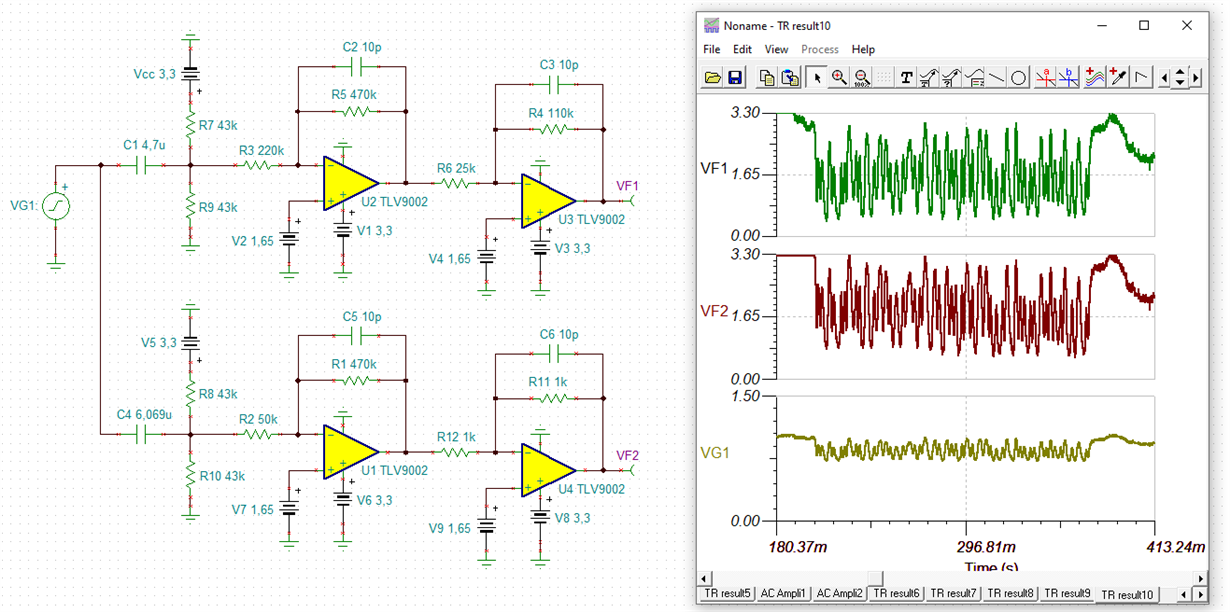

I have an input signal that has a large DC bias with the signal of interest riding on top of that bias. I AC couple the amplifier input so I can gain only the signal. The problem I am seeing is that the input signal can be steady for a while, and when the signal starts, there is a large settling time where the AC coupled output drops like the below input. Circled in red is the area i'm talking about

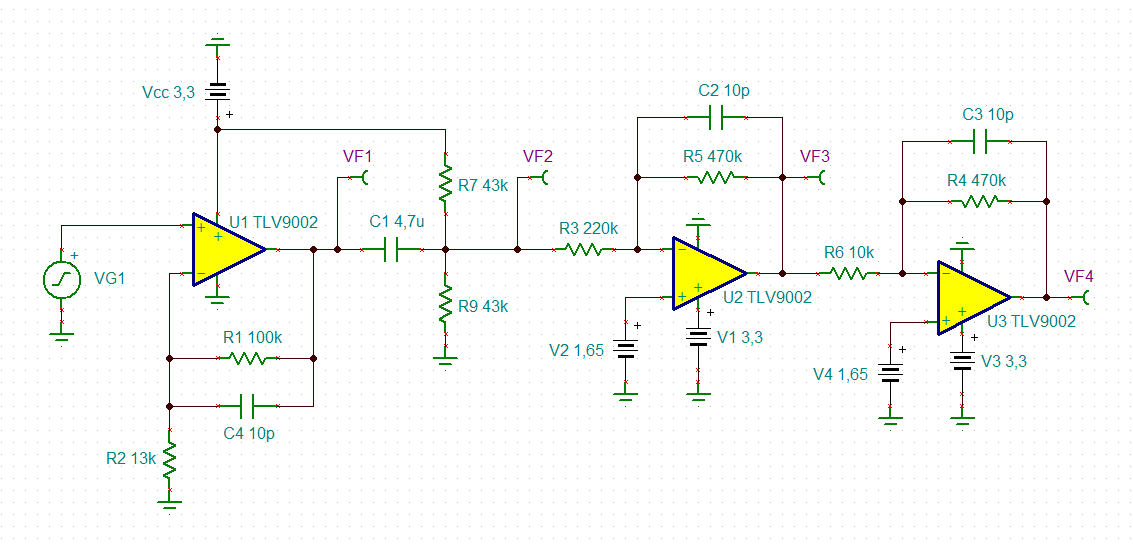

Frequencies of operation = 50Hz to 2kHz

Gain 7.2V/V

Single supply (3.3V)

AC coupled input biased to mid rail

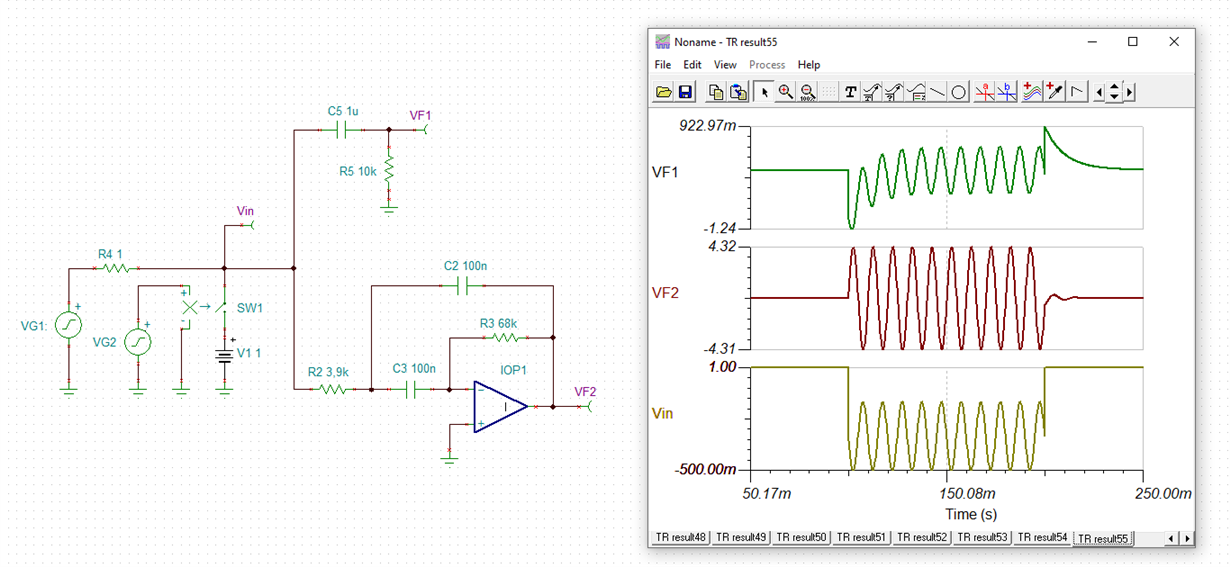

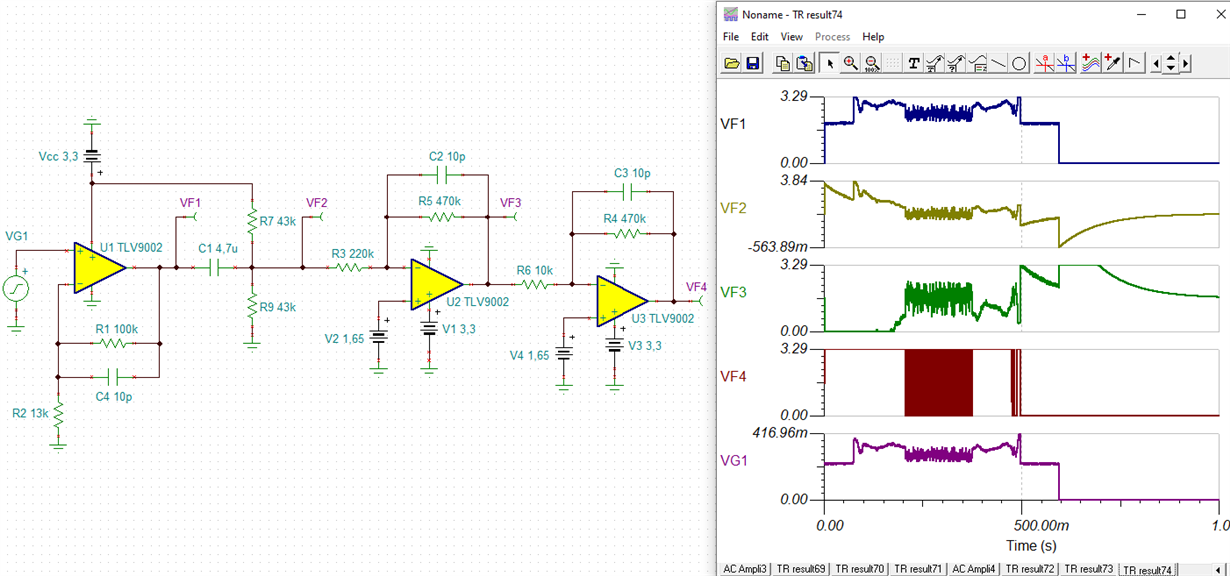

Here is the input signal "VG1"

Here is the output signal "VM1"

And here is both input and output on the same capture

If we zoom into the area of interest:

You can see that the Yellow signal (input) does not dip down in the start like the Blue signal does (output).

Now I'm assuming this is the AC coupling. Because of the DC offset of the input.

Questions:

1) Why is it doing this?

2) How do a get rid of this or reduce this?

Let me know if you need anything else from me

Thanks