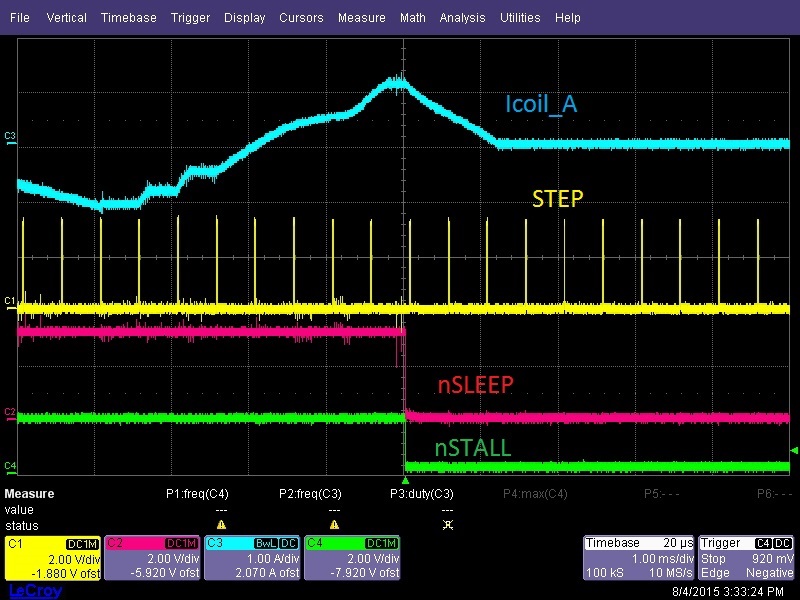

I am using a DRV8711EVM to prove feasibility of using the Integrated Stall Detection feature to detect an End-Stop/End-of-motion application in a Stepper-Motor (which would also likely have me go with the DRV8711 for a solution). For my application, this would be a very nice feature/cost-reduction to add in for a new project I am working on.

Unfortunately I am having a hard time to get it working.

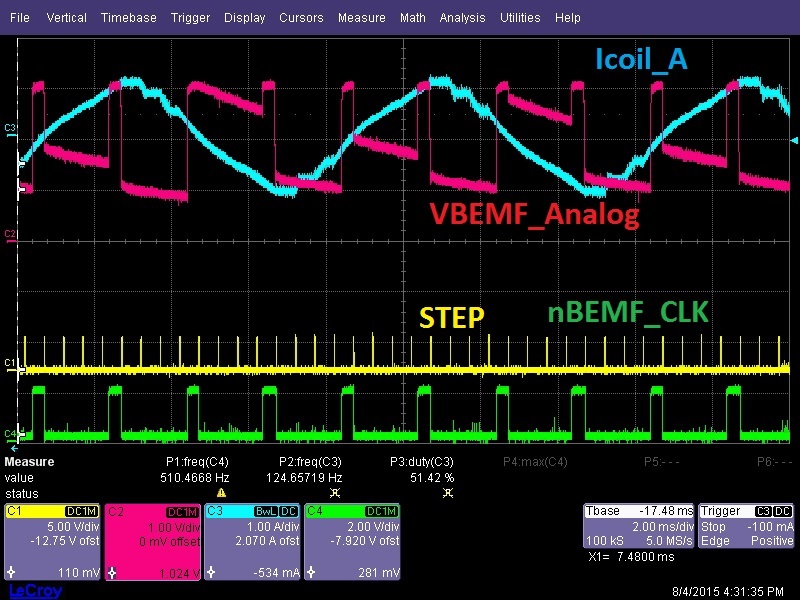

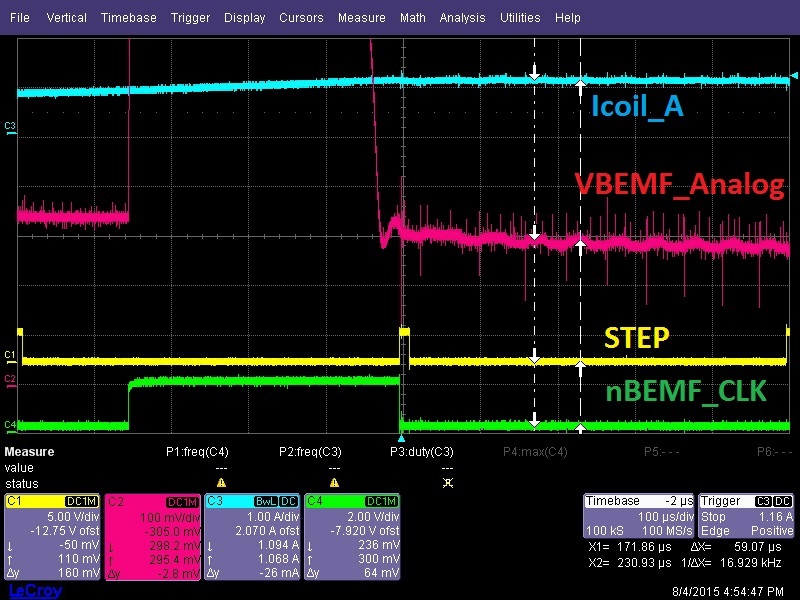

The datasheet and DRV8711_QuickSpinTuningGuide discuss how finding the appropriate parameter values needs to be done empirically because of how monitoring the BEMF works, and how this can vary from motor-system to motor-system. I believe I have a solid understanding of how it works and the various registers that need to be played with

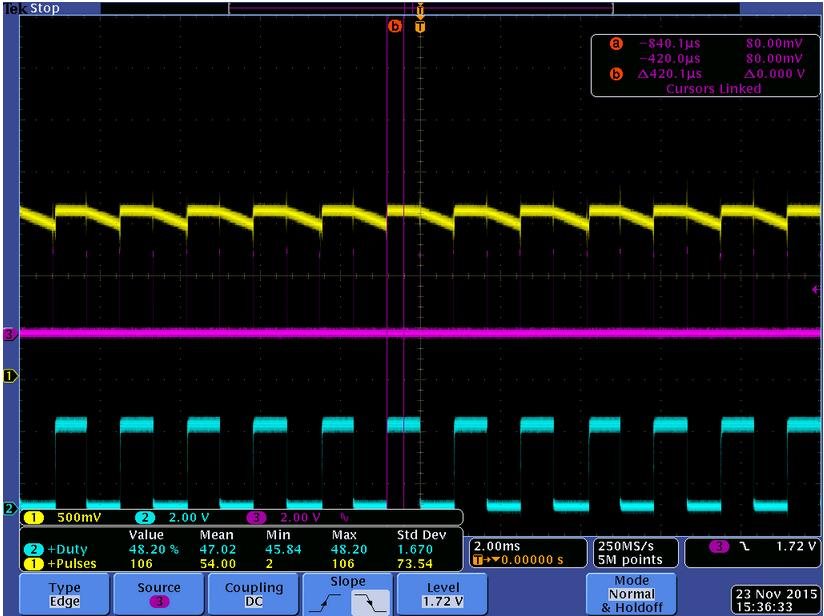

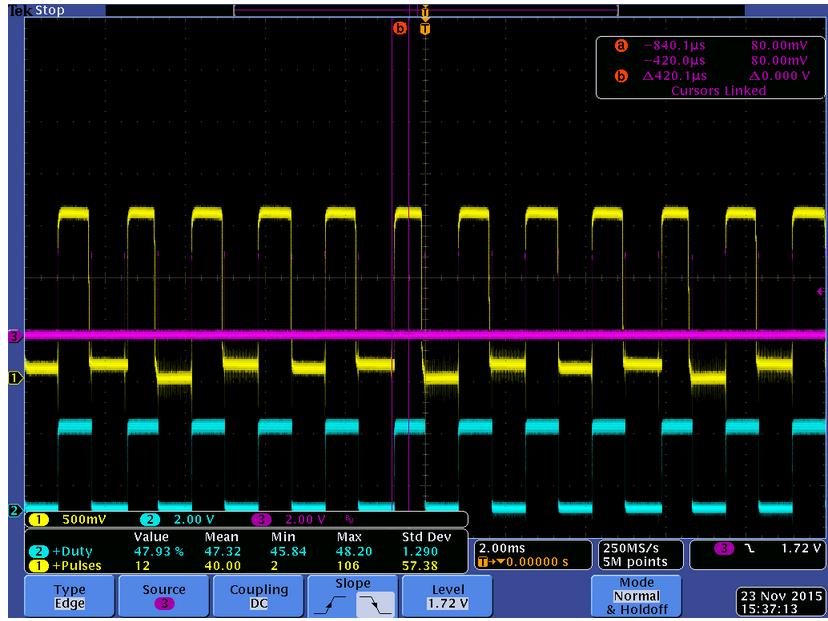

TI has provided SOME basic tips to get this working, but I could still use more advice than what's listed in the guide as I am still struggling. Perhaps if you could recommend a way of triggering/seeing the signal on the scope that would be helpful (I tried, but with all the H-Bridges, coils, timing, not knowing magnitude the kind of signal I was looking for, etc. I just didn't have any luck)

Questions:

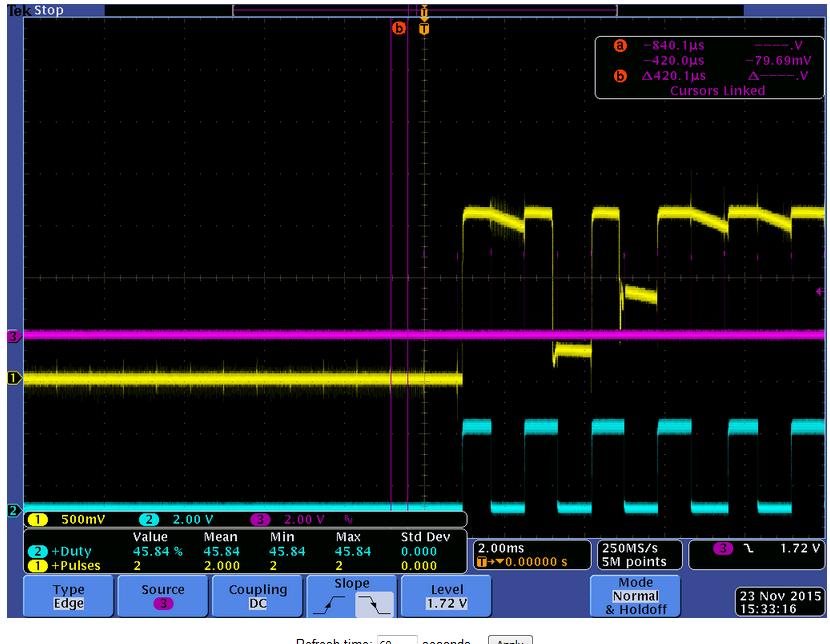

1) Because it monitors BEMF, this will only be valid if the motor is spinning at some minimal speed before it encounters a Stall. What crude estimate of minimum speed are we talking about? (e.g. 10 RPM, 100 RPM, 1000 RPM?)

2) What resolution Micro-Stepping is recommended for Integrated Stall Detection? The Guide has 2 recommendations: a 16-step uStep in Table 1, and a 4-step uStep in Table 2. I know Full-stepping does not work.

3) The guide recommends increasing SDTHR (threshold) and VDIV (Vbmef_divided) until it is working correctly, but makes no guidance to SMPLTH (duration of integration sample), Torque register (I assume that although the Torque is for necessary drive current, the VBemf should also be proportional to the Torque you apply to the motor), and ISGAIN (as it also affects torque).

4) As this is new for us, and because it is so empirical, do customers require this level of calibration for every setup? Or if properly tuned with enough margin, is it possible to create a standard set of configuration for operating within manufacturing tolerances; e.g. same family/PN of motor, mechanical load, etc.?