Other Parts Discussed in Thread: TPS54160, BOOSTXL-DRV8301, DRV8303, DRV8301

Dear comunity,

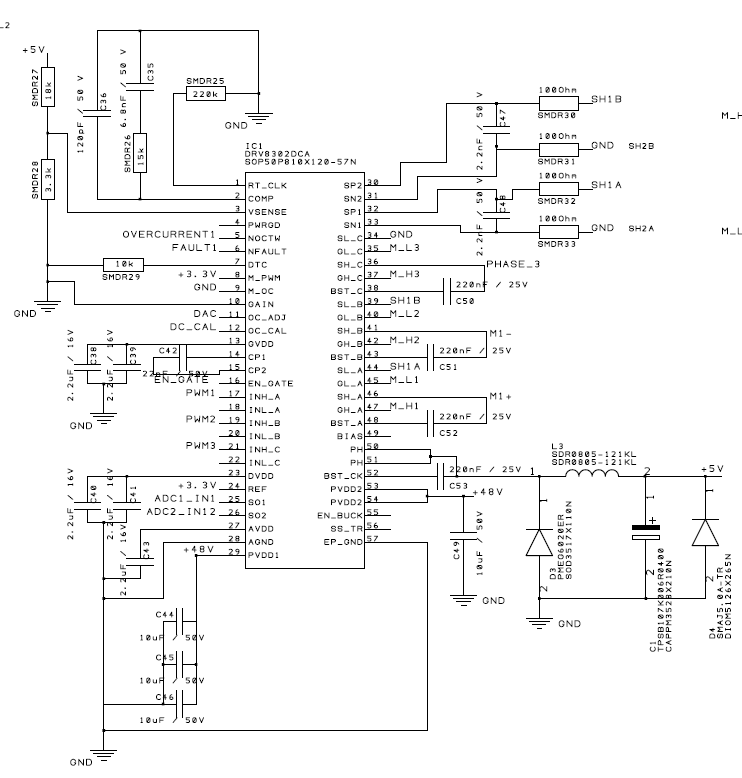

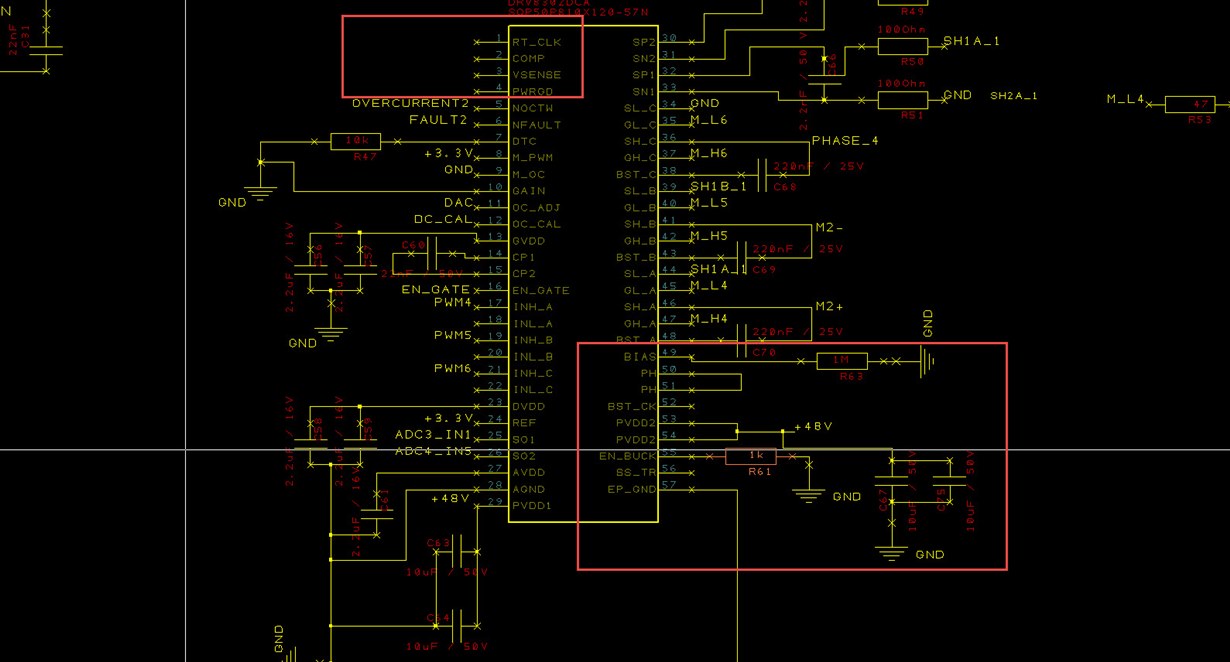

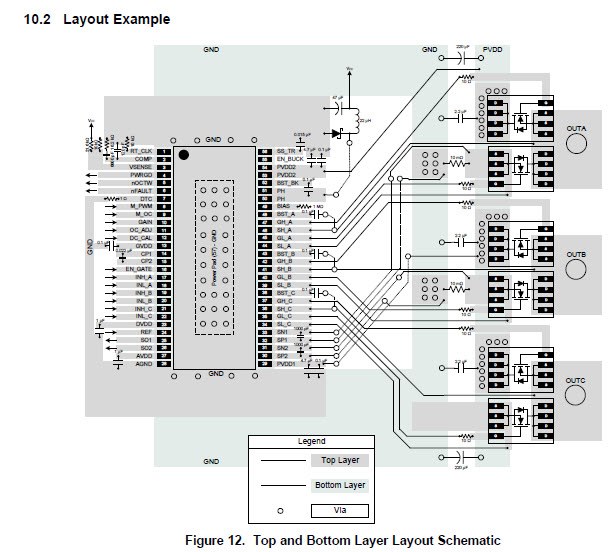

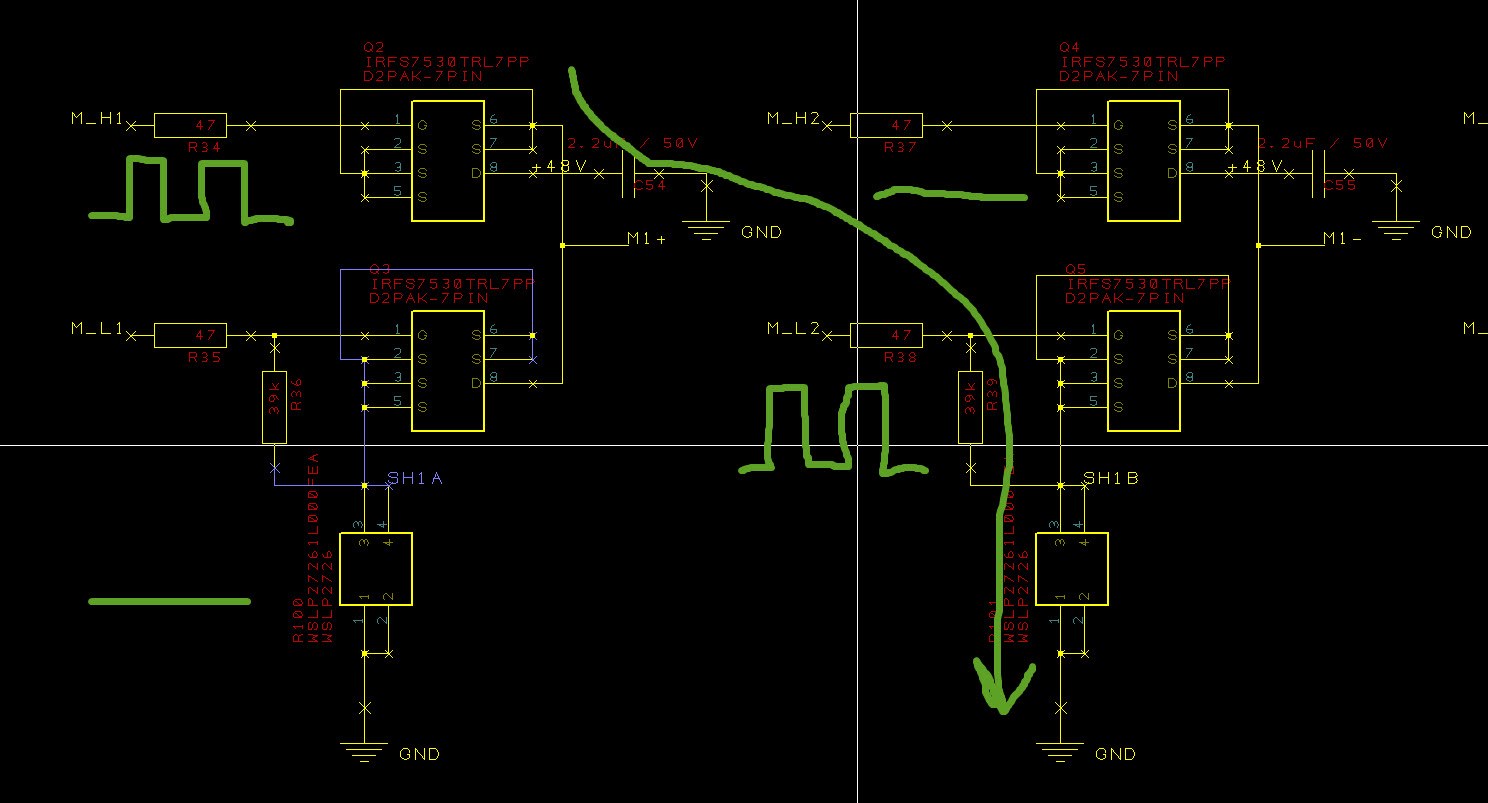

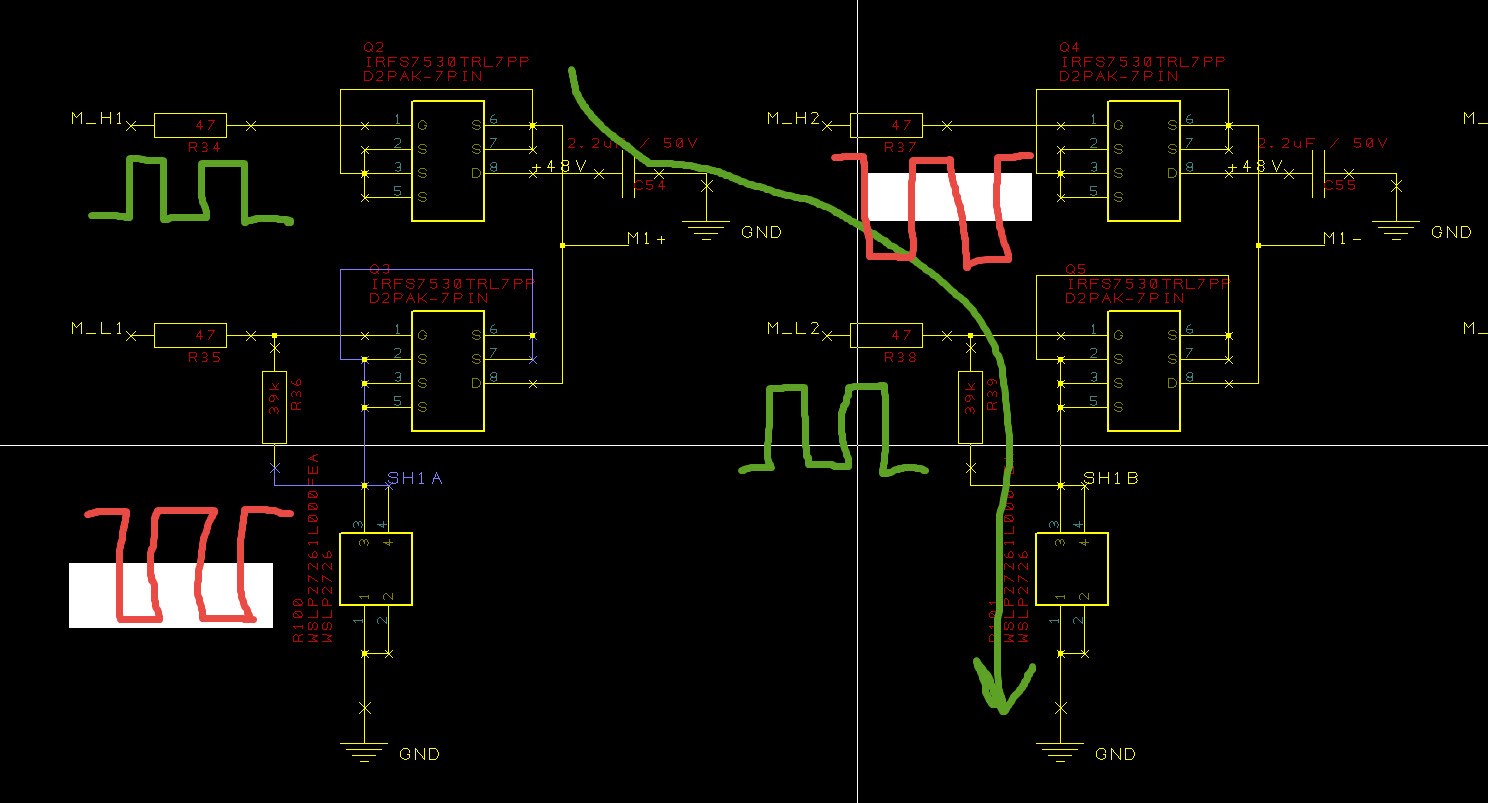

it seems I have problem with buck converter of DRV8302. I soldered it acording to this schematics:

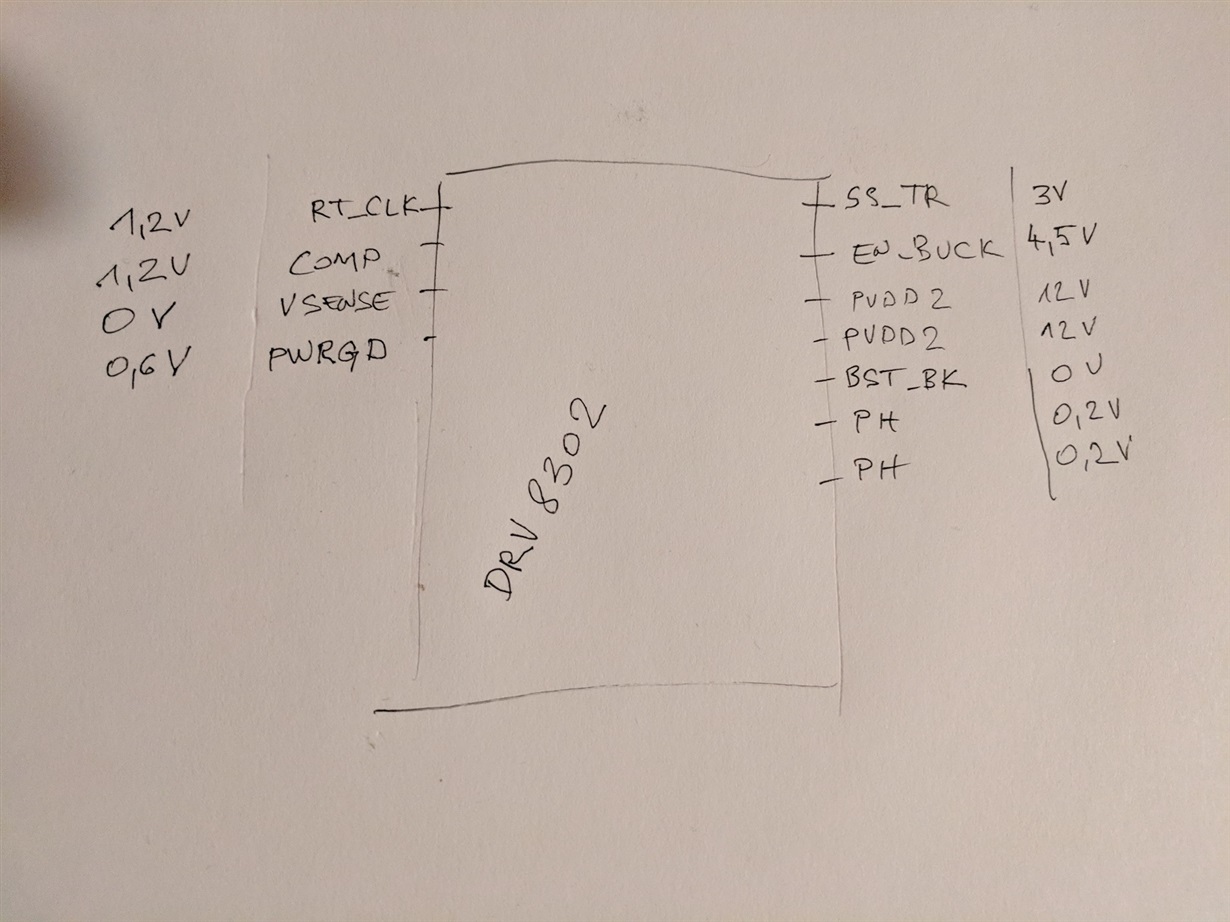

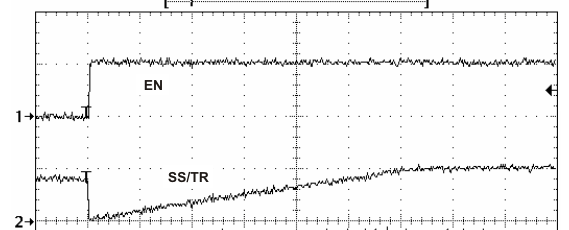

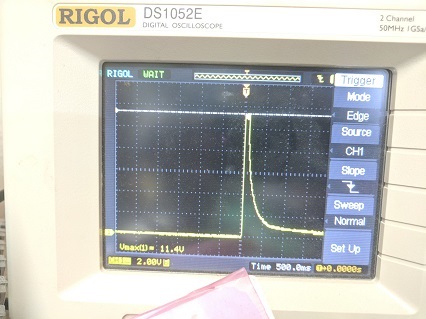

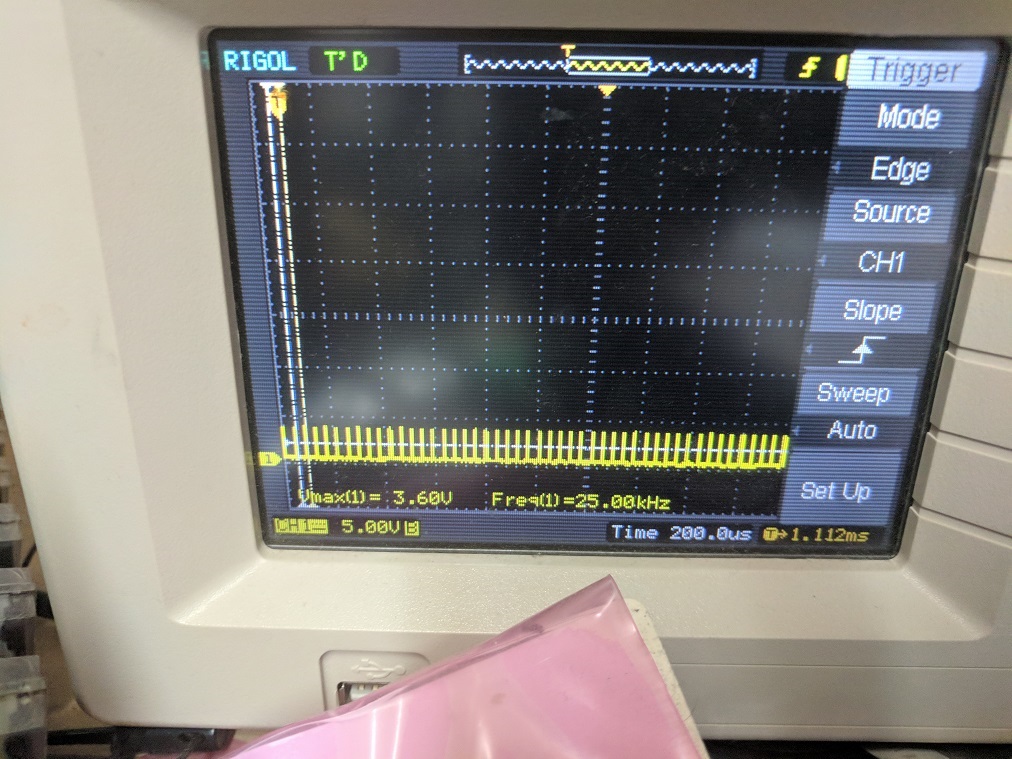

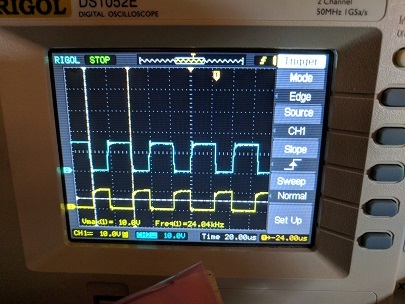

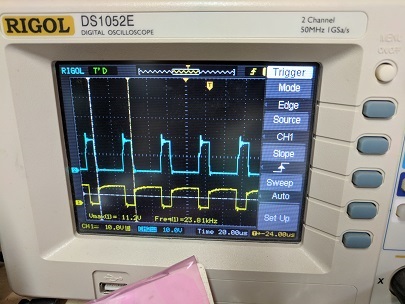

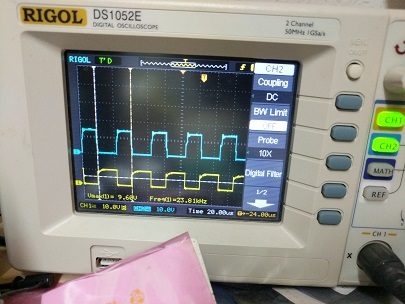

The voltage levels I get on relevant pins are as follows:

I am powering chip with 12V VDD.

(not)FAULT is pulled low - can you maybe suggest what else could I check to find what is causing this non desired operation.

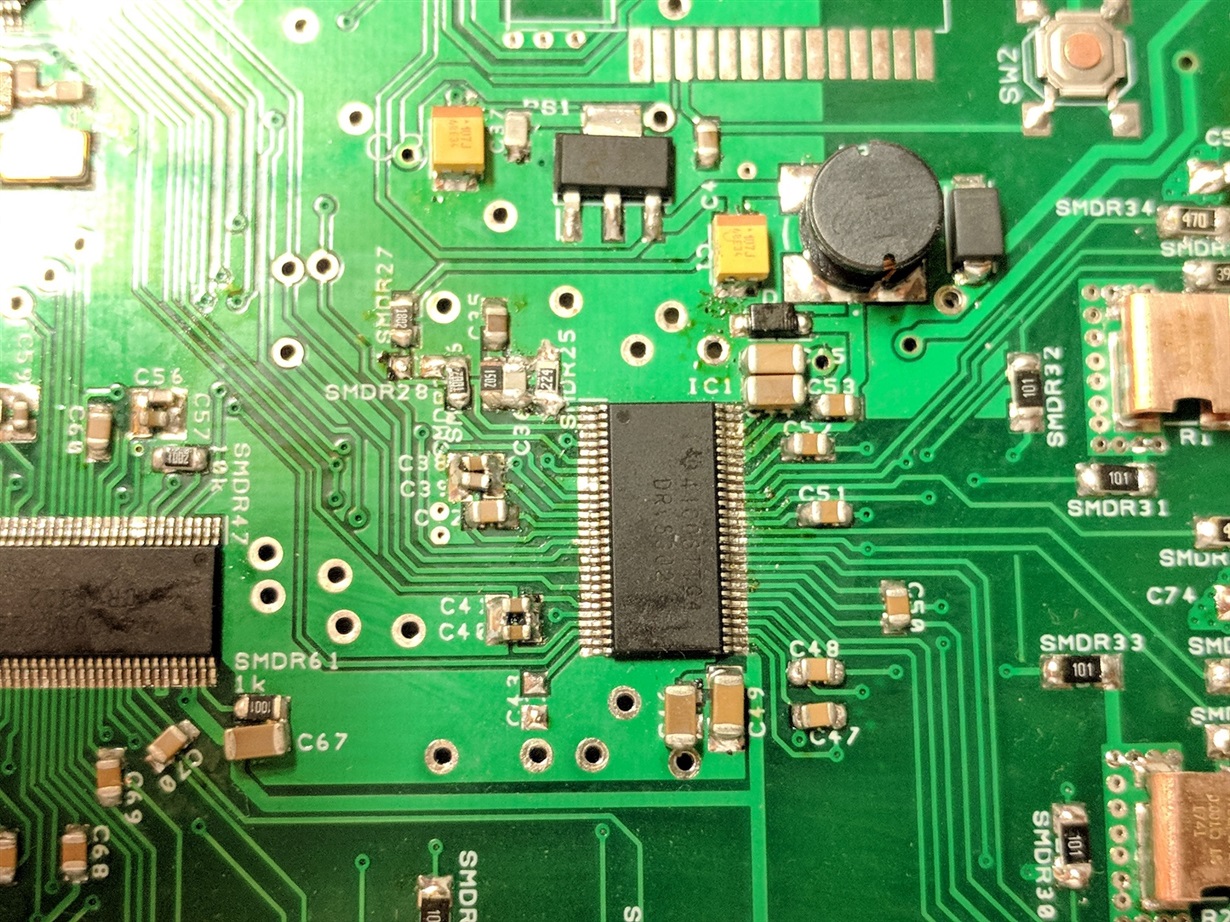

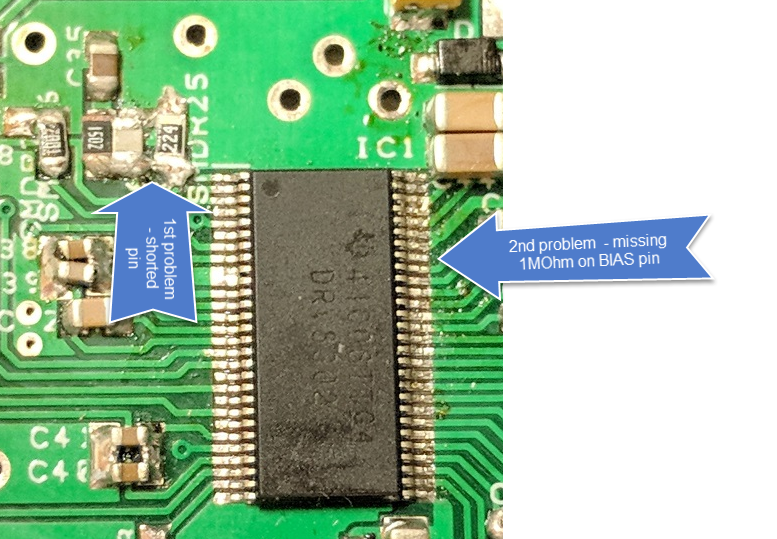

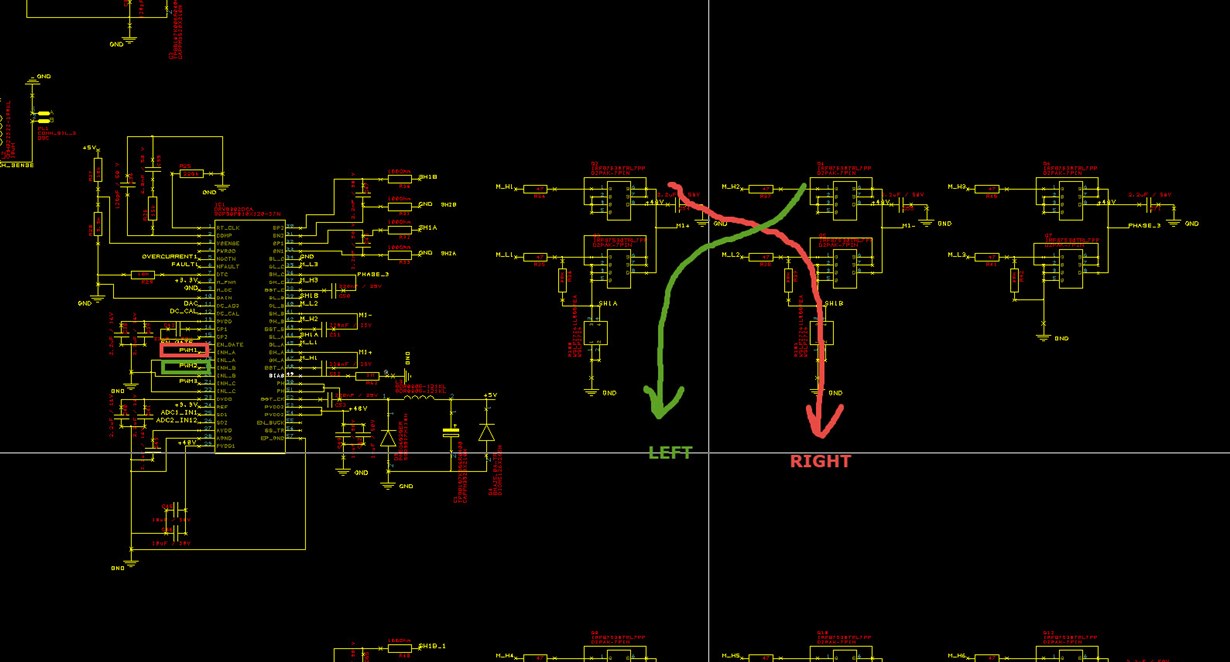

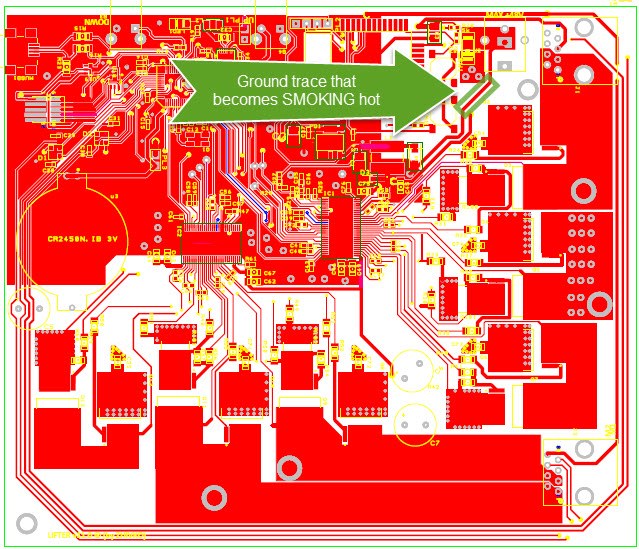

Here is also pcb of board if needed.