Other Parts Discussed in Thread: OPA1688

Hi TIer

What about the different between OPA1652 and OPA1688.

Is these two chip can drop in replace by each other?

If can not , which parameter we need pay more attention to ?

Thank you very much.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hello,

I am currently working with our marketing team to provide a table of replacements for you. I will get back to you shortly on this.

Best Regards,

Chris Featherstone

Hello,

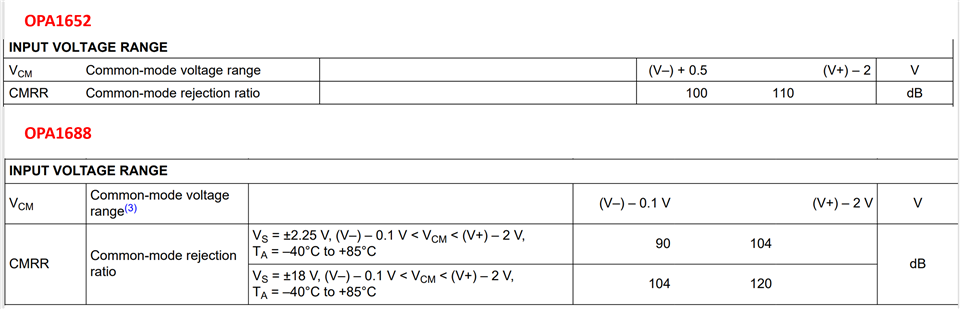

There are some differences that I highlight below. It will depend on the key care about's for the customer. The input and output swing conditions are important to compare. Note that the OPA1688 has a wider input common mode range.

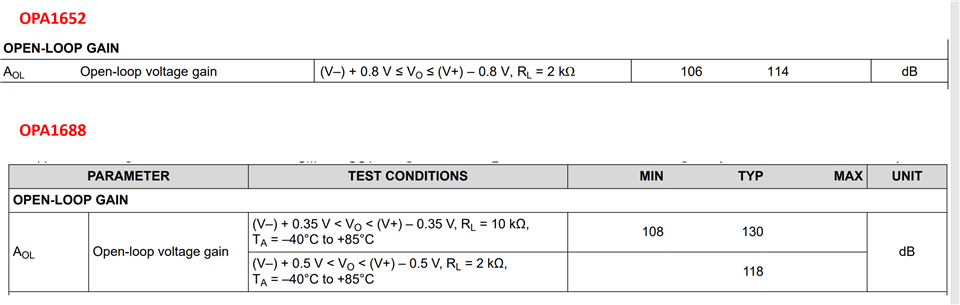

The OPA1688 has a wider linear output swing range as well.

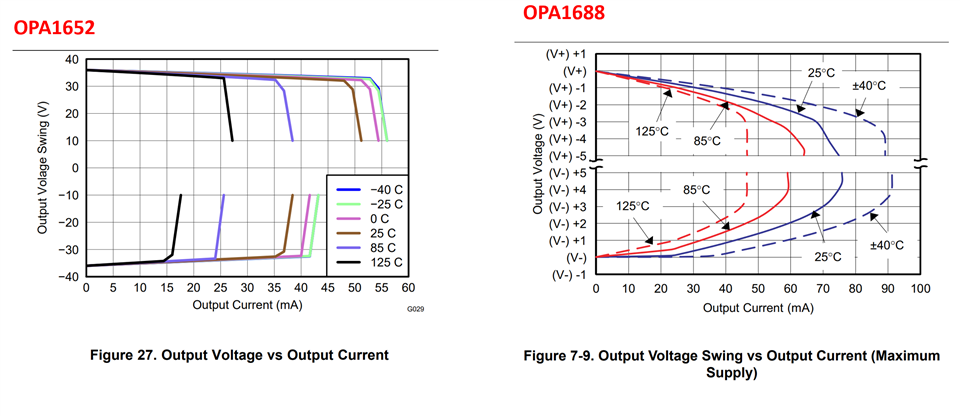

The output drive for both sourcing and sinking current is more symmetrical for the OPA1688. In addition the OPA1688 has more output drive capability. Depending on what the load is on the output of the amplifier, this may be of interest to look at. This parameter is useful to look at for output power when driving headphones for example.

Our marketing engineer pointed me to the “compare” function in the audio parametric table.

Here’s a premade link to your selections

You'll notice some differences such as gain bandwidth product and Iq. The input bias current has a tighter specification at room temperature for the OPA1688 and is also specified over temperature.

Hopefully this information provides a good starting point for you to guide the customer. If you have additional questions let me know and we would be happy to help.

Best Regards,

Chris Featherstone