Hi,

Context:

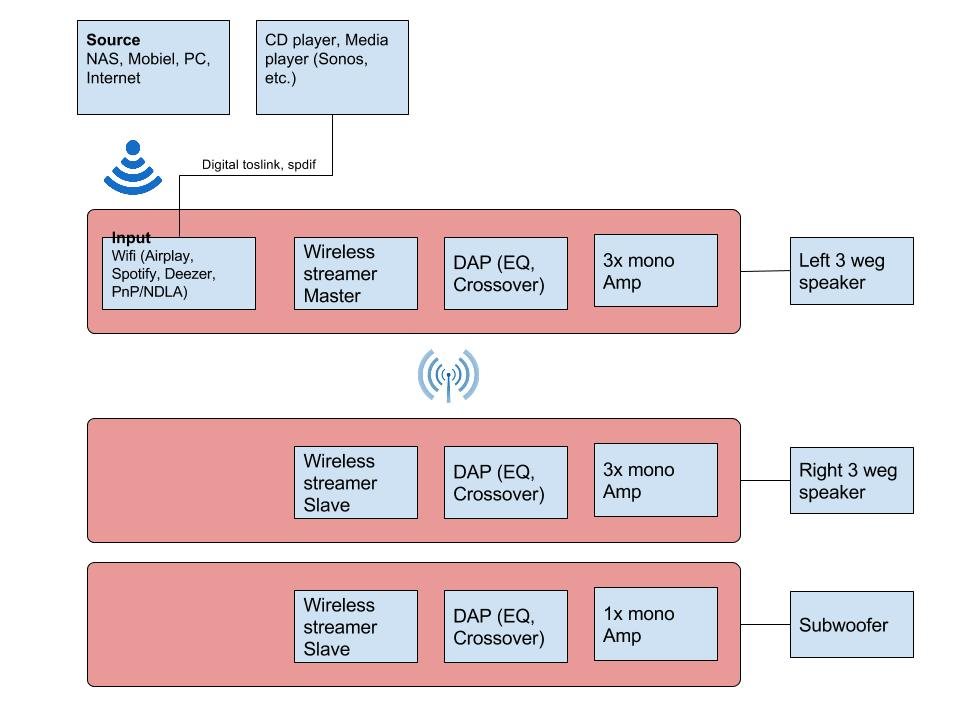

I'm writing a project candidate for Electronics students. The goal is to design and build an audio board for a full range 2.1 audio system (stereo + sub), which is completely wireless and can play from an accu.

The demo system must be a 3way active stereo system (tri-amping) with no additional gear/enclosures, other then the speaker enclosure. Other configurations should also be possible, like a 4way and multiple subwoofers.

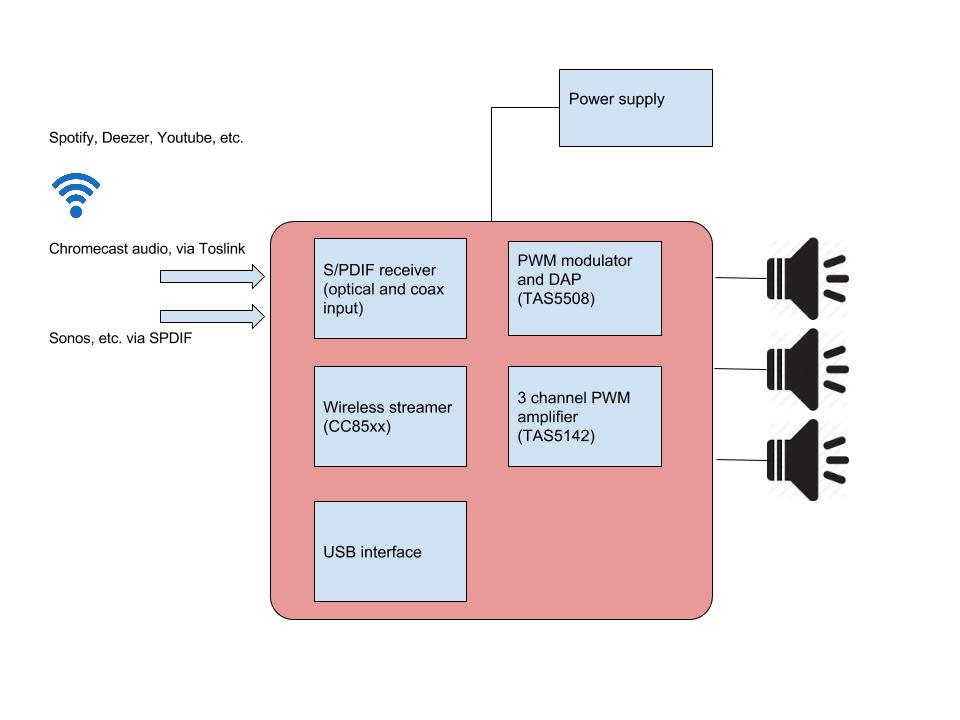

Because of these criteria, I need a very small and efficient solution. One of the solutions is a board for each loudspeaker with: CC85xx (Wireless) and TAS5508C (PWM modulator) + 51xx amp. The first board will act as a wireless master and the others as slaves.

Question:

From what i understand is that the TAS5508C has a DAP that can be configured with the GUI software via a config file uploaded via USB. If I would have three of those boards, do I have to change the configuration on all three of them? For instance if I would make a change to the EQ or Crossover settings (biquads), do I have to update all 3 boards separately.

any thoughts? alternative solutions?

thanks in advance!