Part Number: TPA3255

Other Parts Discussed in Thread: TPA3251EVM, , TPA3245, TPA3251

My customer is seeing the following issue when using the TPA3255EVM:

I am having an issue with a TPA3255EVM board purchased recently. It is not working as expected in PBTL mode. It appears to be entering a CB3C over-current fault as the input level approaches the point when one would normally start to see some activity on the OTW pin. The outputs shut down temporarily and then it restarts. The EVM works perfectly in stereo BTL mode all the way into hard clipping.

I am using the EVM with no modifications except re-configuring the jumpers per the table in section 3.2 of the EVM guide. I am using a 4 ohm resistive load and running the board at 36 Volts from a big HP analog power supply and supplying it with a 1kHz signal from a high quality signal generator. I have rechecked everything at least a dozen times.

BTW, I also have a TPA3251EVM operated under the same conditions and it works perfectly in both stereo BTL and PBTL modes to full power.

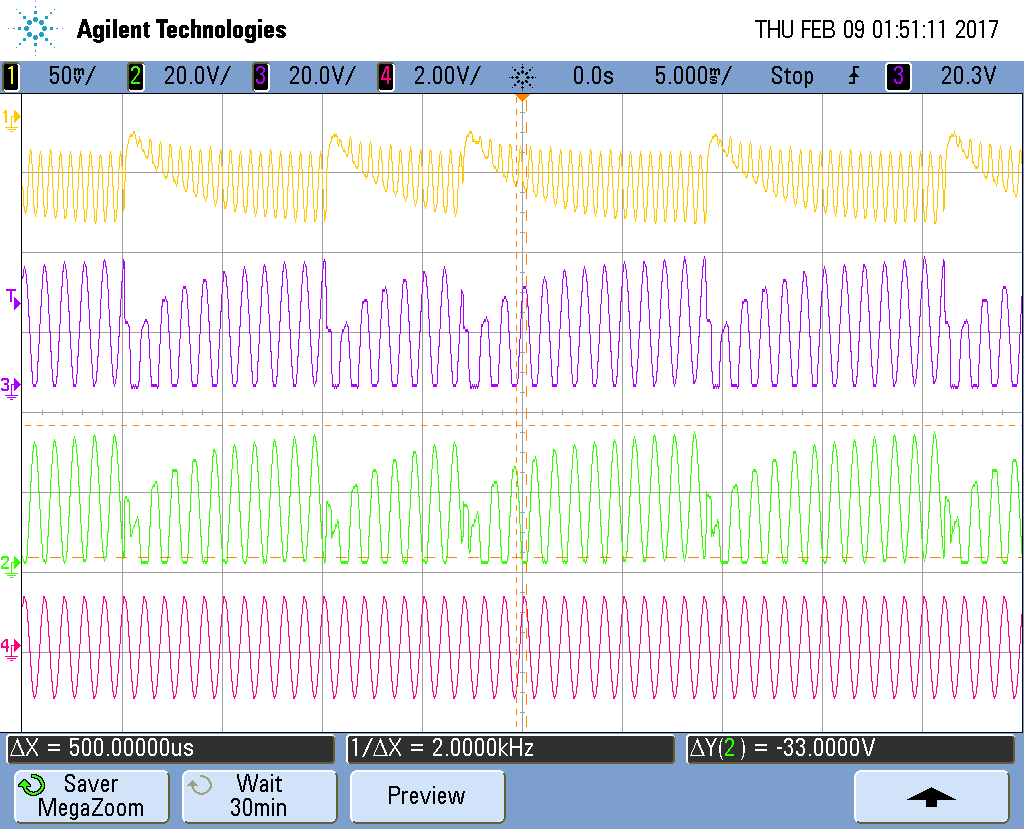

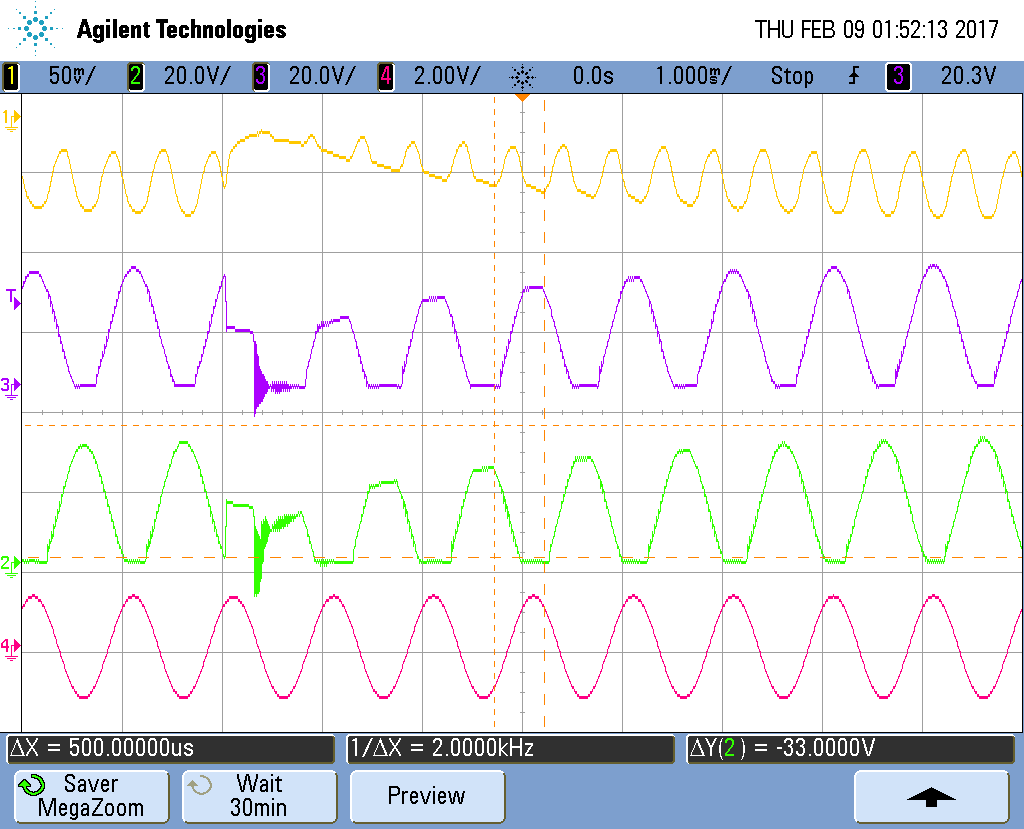

Here are a couple of scope shots;

The image tpa3255evm_1 shows several shutdown/recover cycles. The top trace is the power supply input current measured across a 10 mOhm shunt. The 2 and 3rd are outputs A-C and B-D to a 4 ohm resistive load. The bottom trace is the input signal. The second trace is a zoomed version of the first.

I forgot to mention that there are no signals on the OTW or Fault lines. Both are high.

I double checked everything in table 6. I have done so half a dozen times already. It still operates the same.

Based on the indicators (no activity, both hi). I thought it was the unbalanced O/C speaker protection (section 9.4.1.3) not a temperature warning. The CLIP/OTW pin shows when the outputs start clipping which is what I referred to in my original email.

Please let me know if you have any further questions for the customer.

Thanks for your help with this!

Richard Elmquist