Hi team,

As written on the datasheet 8.3.3 Clock Outputs, any unused output pin should be left floating with a minimum copper length (see note below) to minimize capacitance and potential coupling and reduce power consumption.

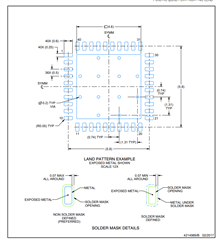

And This way during reflow, the solder has the same copper area as connected pins. This allows for good, uniform fillet solder joints helping to keep the IC level during reflow.

Sorry, I couldn't understand what this mean. The below undestanding is correct?

Unused output pins should be left open, but it recommneds that unused ouput pins are also connected as other pins to make the IC connected well to the board. And the picture as below is good example as the soleder mask for unused pins. The picture comes from P.33 of the datasheet.

Could you also expain " the IC level " of 8.3.3 Clock Outputs?

Regards,

Noriyuki Takahashi