Other Parts Discussed in Thread: TPS22946

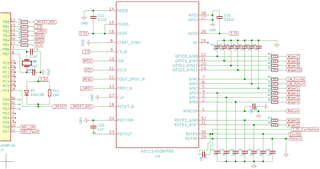

Hi here is a quick overview of the system.

I am designing a battery powered prototype of potentiometer(s) readout. The device displays the potentiometer wipers ratio value in an LCD and goes to sleep after a timeout to conserve battery life.

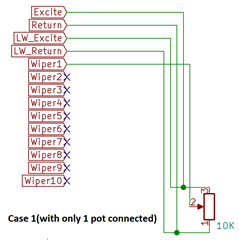

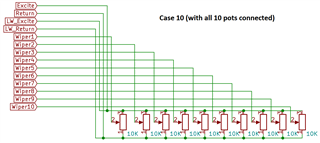

The potentiometers are around 50-100m away from the ADC input pins. There can be anywhere between 1-10 pots connected to ADC. They are 10K pots. I have provisioned 2 inputs as lead wire between excite and ground terminal of pots to be measured as differential inputs. The 10 channels are read as single ended.

Pots are to be excited by 3.3V with the same 3.3V also used as reference inputs REF0 for ratiometric measurements.

1) SPI communication: is the schematic correct (as per the datasheet) or do we also need to connect RESET pin to 3.3V with 10K pot? I want microcontroller to be able to reset the adc in case of any issues.

2) Short: I want to provide some short circuit protection and detection between pot excitation and GND. Since the effective resistance between the excitation and GND can be anywhere between 1KOhms (with 10 pots connected) to 10KOhms(with 1pot connected), I think the max current draw should be between 3.3mA - .33mA.

I was thinking to implement a switched excitation source(3.3V_Excitation) where first we check for short circuit and only then provide the excitation for the pots. This is to protect the circuit and optimize the battery life by protecting against the unwanted current draw.

I found TPS22946 as the smallest switch with fault detect and shutdown option(for no pots connected and device in sleep). I was thinking of using this to protect against and detect the short (i.e. when the current exceeds 30mA limit). However my maximum current draw should not exceed 3.3mA so anything more than that is error condition. Is his correct? Are there any similar devices/switches that you can recommend which fits my requirement? Is this the correct approach.

Also I found out the burntout detect feature of this ADC but the datasheet says its difficult to detect cable shorts using this feature. I also did not find much info on how I can implement this feature especially in my case.

3) The wipers do not move too quick. I can get away with 5-20 SPS and display the average of the readings to be displayed in LCD. Which sampling should I use to get the best noise rejection? Any tips for input protection in my case. I was thinking of protecting all the 14 I/O pins to the pots with TVS diodes (3.3V /5V). Any suggestions for a standard protection system?