Other Parts Discussed in Thread: CDCE72010, ADS4249

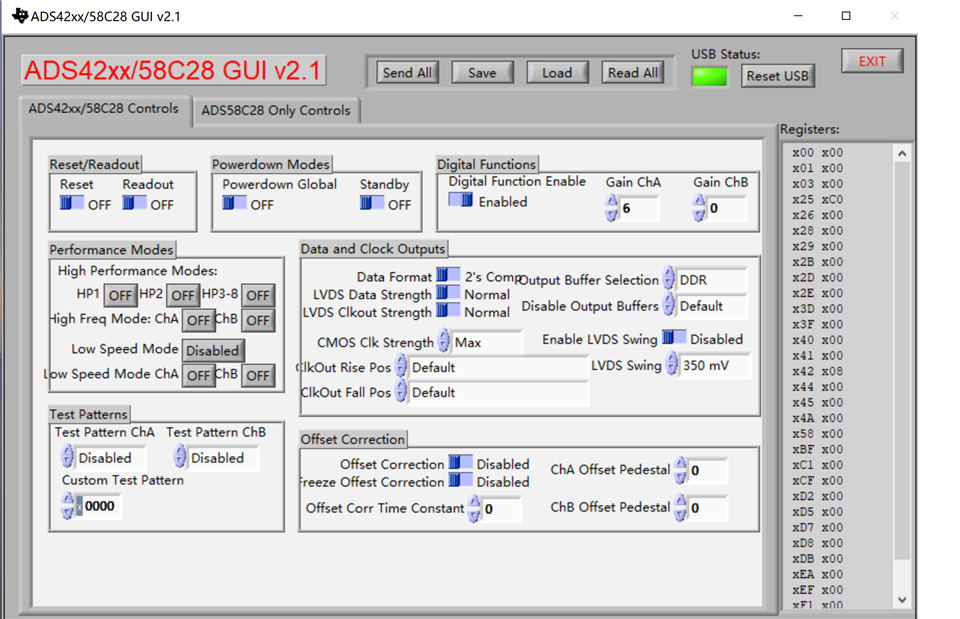

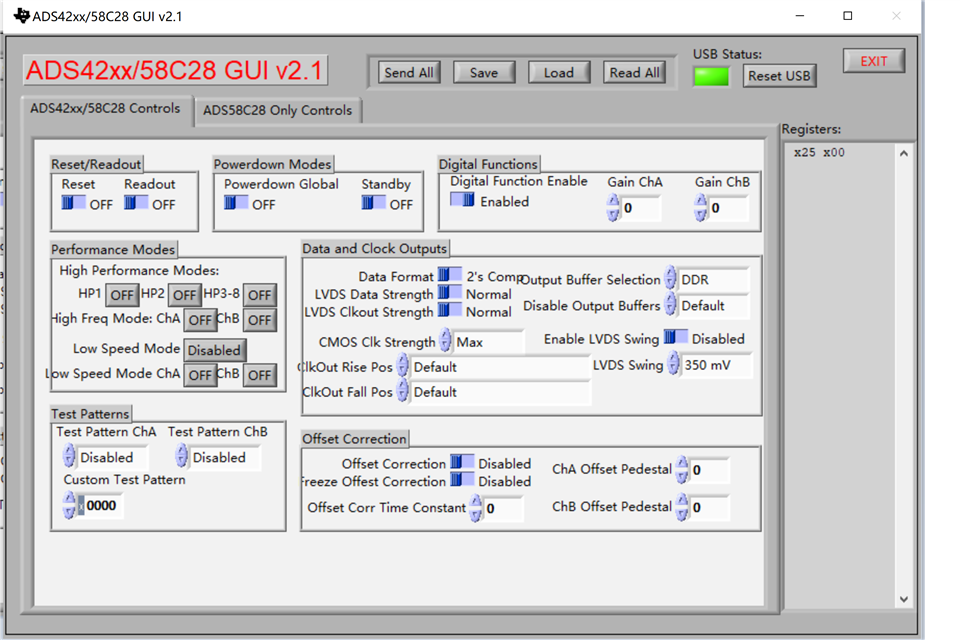

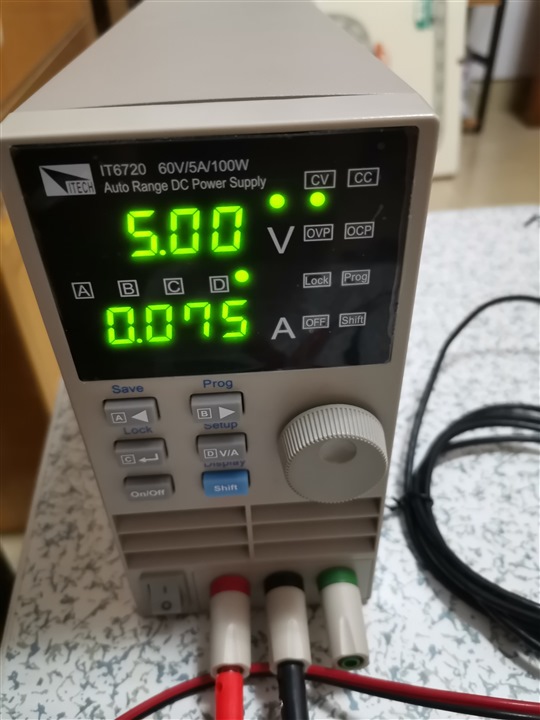

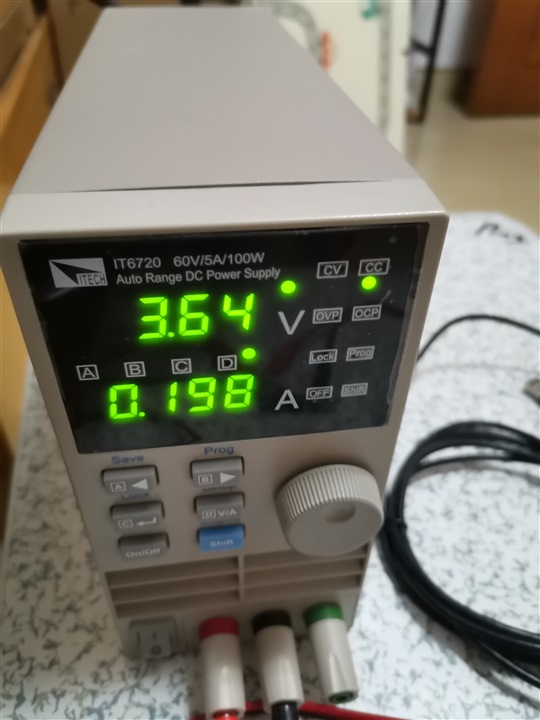

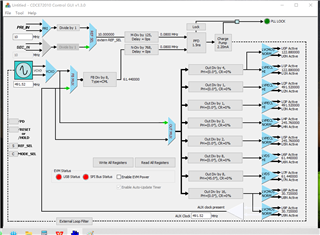

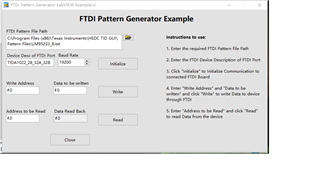

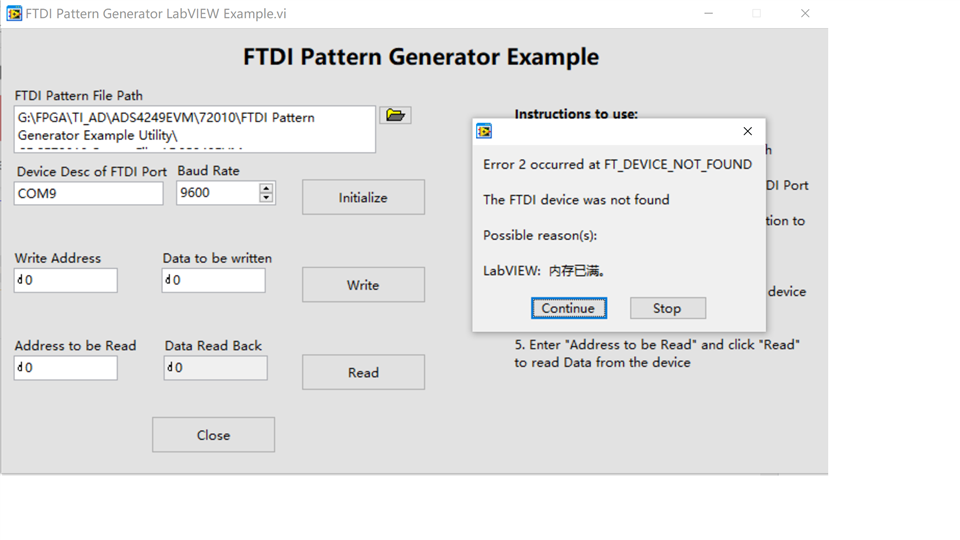

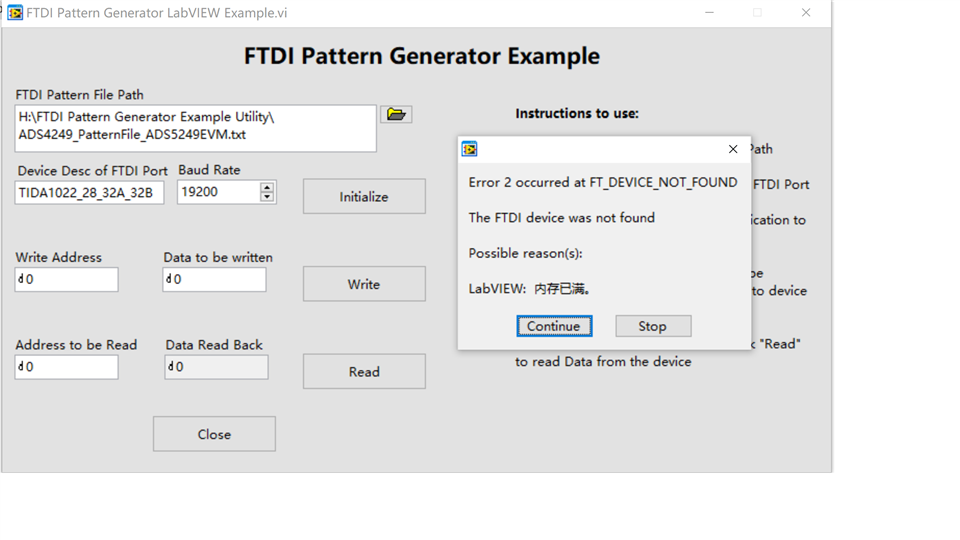

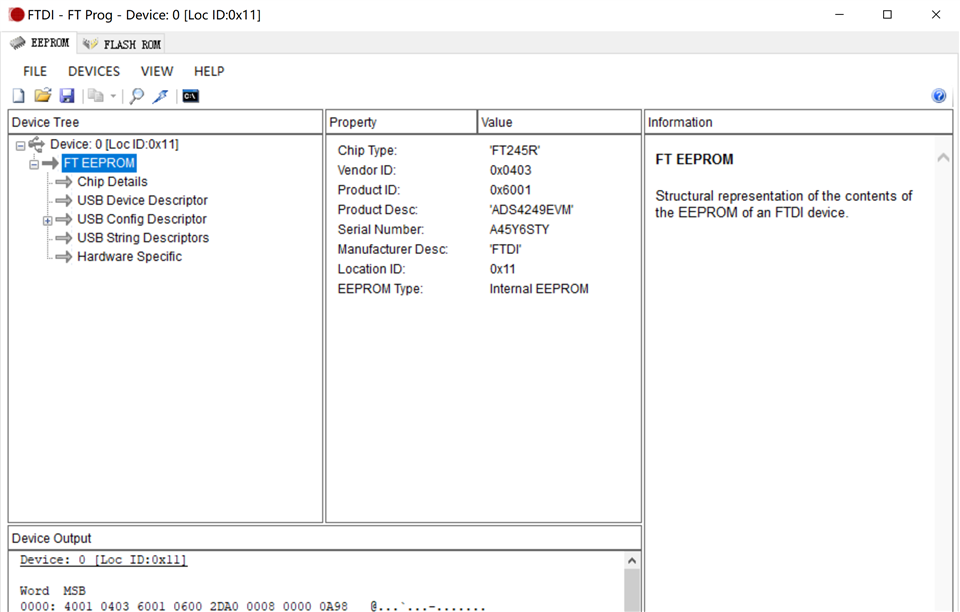

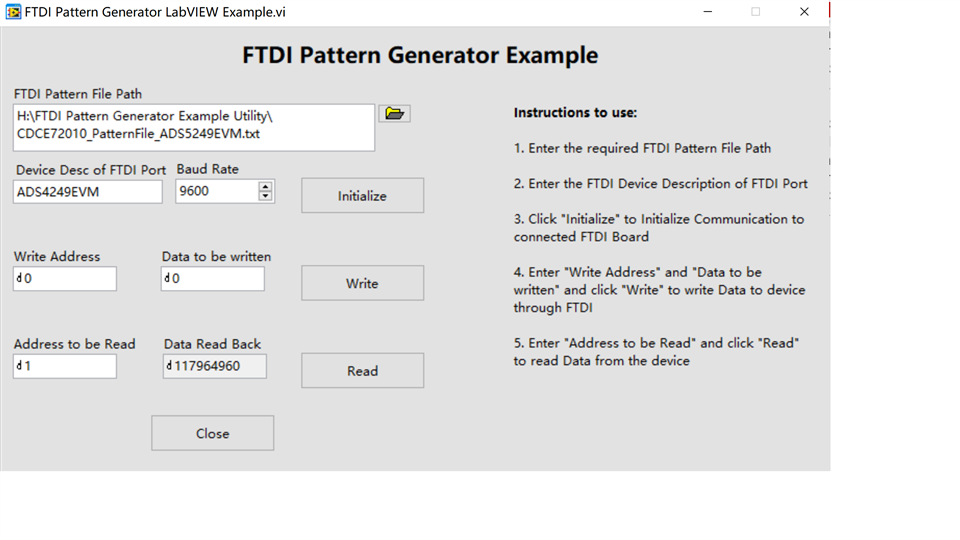

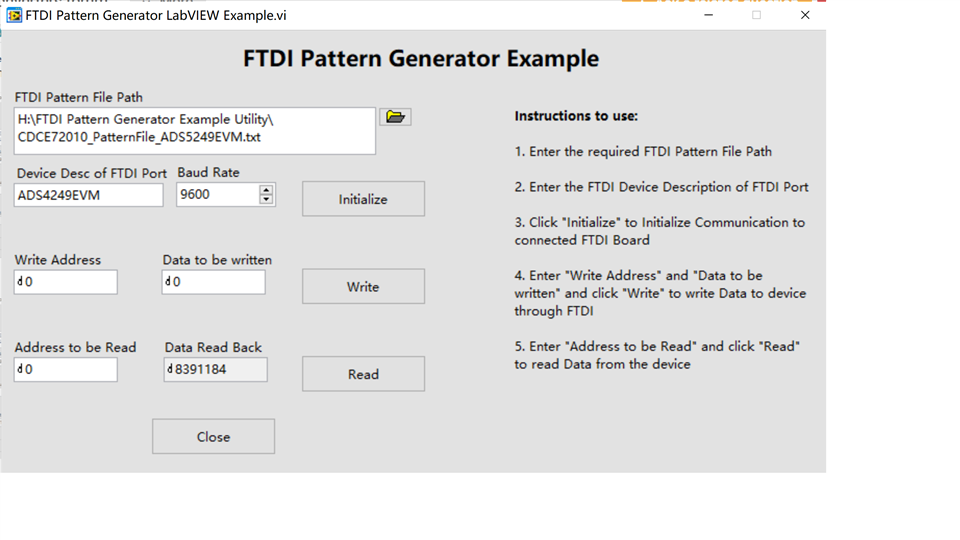

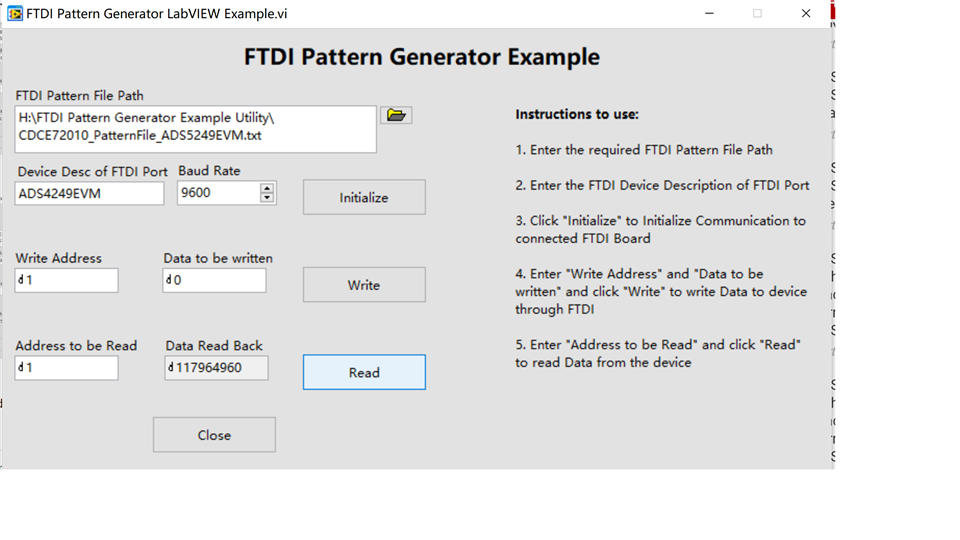

Hello, I bought ads4249evm in Ti mall with order No. t0512046. When powered on, it was found that cdc72010 was very hot and the USB connection could not be recognized(ADS42xxx SPI GUI (Rev. B) and CDC72010 GUI). The measured + 5V displayed 5.2v, + 1.8va and + 1.8vd displayed 1.7V, + 3.3V_ CLK displays 3.23v and the voltage is normal. How to solve the problem. The jumper is factory set and has been checked with the user manual.thank you.