Other Parts Discussed in Thread: ADS124S08

Hello Guys,

Good day.

Our customer is designing a board that requires 12 ADC channels, 6 are differential and 6 are single ended. Can the ADS131M06 be configured to support the 6 single-ended ADC channels?

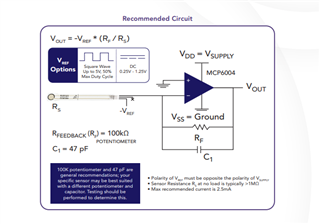

Additionally, do we have a reference design for the ADS131M06 illustrating the ideal power configurations with the designed for components list?

Thanks and regards,

Art