Other Parts Discussed in Thread: ADS124S08

Hello,

Some background on my design:

I am using an ESP32 to interface with an ADS124S08 ADC module. I am using the EVM, so I jumped JP1 to avoid using the onboard processor and have tied the appropriate SPI and GPIO pins between the ESP and the ADS. I have a variable voltage divider circuit running from the 3.3V output pin of the ESP as the input to the ADC at analog input A10 on block J9. The highest voltage this port will see is half of 3.3V or 1.65V, so I know I'm operating within the input range of the ADC. I am also using the internal 2.5V reference and have configured the appropriate jumpers accordingly. I have probed around the EVM's pins and test points to verify that the appropriate voltages appear in their places. The ADC is set to sample 20 SPS in continuous-conversion mode.

My problems begin when I try to start reading the ADC's conversion results. The entire configuration phase goes very smoothly and the ADC starts sampling. However, its sampling behavior is very finicky. Sometimes it runs for a long time, other times the program stalls almost immediately after taking its 3rd or 4th sample. What I notice is that when I power up the EVM, the red LED turns on. This LED turns off when sampling begins and stays off so long as there is a steady output stream on my serial monitor reporting the values of the samples being taken. When the program stalls however, I notice that this red LED turns back on.

I'm hoping this LED can indicate whether this is an issue on the software end of the design or if I did something incorrectly with the configuration of the reference/power of the ADS EVM.

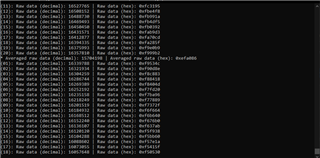

Another issue I am noticing is that the value read after DRDY is pulled low and 24 SCLK cycles are sent is past the cap defined in the ADS124S08 datasheet (0x7FFFFF), which obviously doesn't make sense. Does the input from which data is read have to be configured in the configuration software or does the ADC somehow only read the data on the channel a new conversion is available on? I don't recall seeing something about this in the datasheet, but maybe I didn't look hard enough. An image is attached to show the large ADC readings and the mid-conversion stall.

I would appreciate any help/feedback, thank you in advance for your time and help!

- Denis