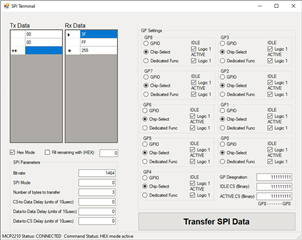

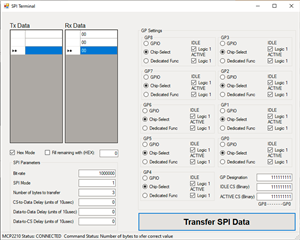

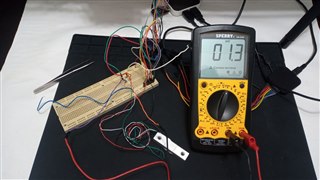

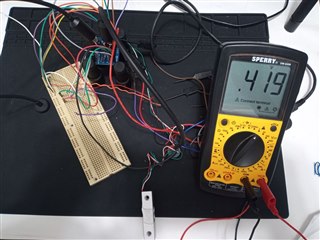

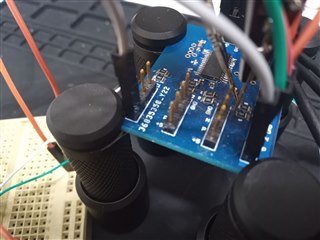

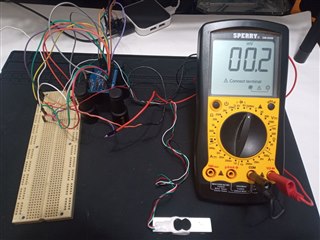

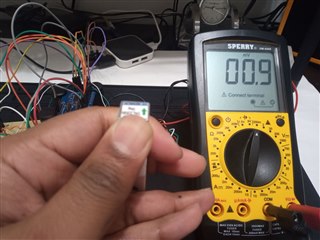

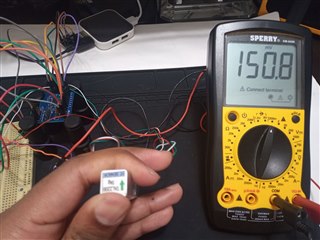

Based on the previous post https://e2e.ti.com/support/data-converters-group/data-converters/f/data-converters-forum/1037254/ads1234-minimum-circuity-to-get-it-working/3850194?tisearch=e2e-sitesearch&keymatch=%20user%3A498854#3850194 I am having trouble getting this to work properly.

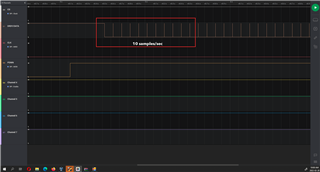

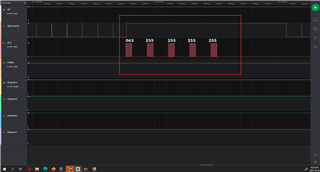

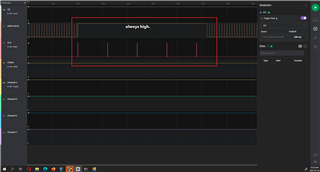

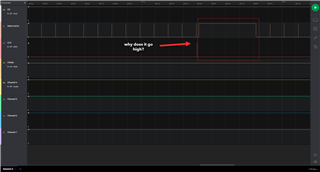

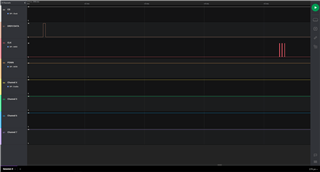

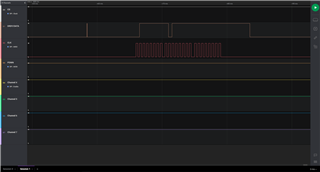

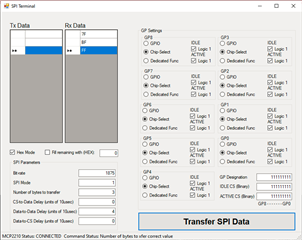

A video showing the issue is at this link: https://ticsc.service-now.com/sys_attachment.do?sys_id=8228a303973d059082c3348c1253af73

Basically the readings are always showing 255. It is not working as expected.

Thank you so much for your help.