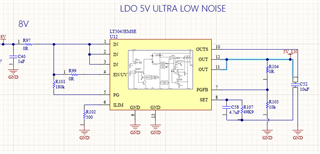

Other Parts Discussed in Thread: ADS1261, , TIPD188, TPS7A94

Hi all,

Due to the chip shortage, I am not able to source any ADS1261 (let me know if you have a secret stock, I am looking for QTY10).

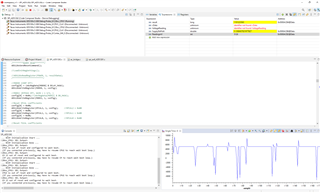

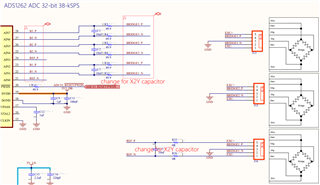

So I am trying the ADS1262 instead. It is pretty similar but the library I an using is a little different. I am using the lib from TIPD188 example.

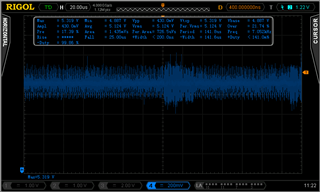

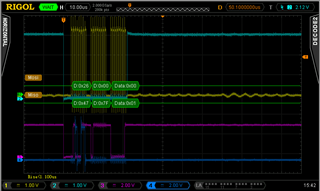

The communication is working well, when I am trying to read to register INTERFACE (0x20+0x02) I receive the 0x05 default value:

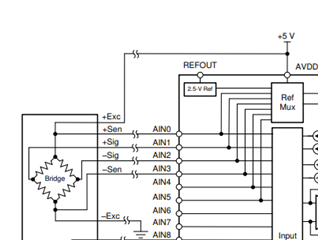

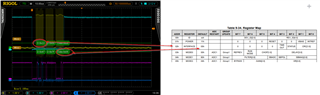

Now I want to configure the pins and references mux to measure my loadcell but I noticed that when I write into the INPMUX register, the value is not saved:

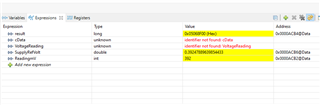

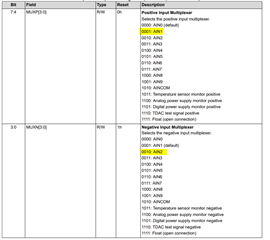

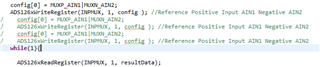

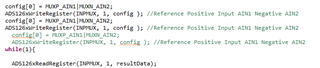

I do a write with MUXP_AIN1(0x10) | MUXN_AIN2(0x02) , then read the register in my while loop:

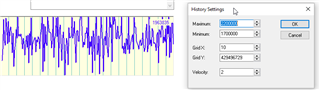

If I write only one time, instead of reading 0x12 I read the default value 0x01

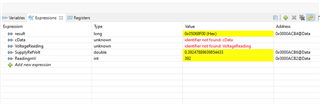

Now if I write twice, I read the right value 0x12:

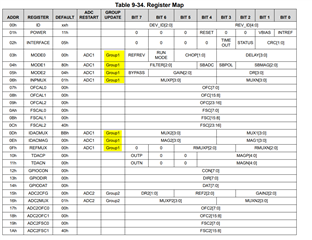

I don't really understand the statement in the datasheet page 87 saying: The MODE2 and INPMUX registers are modified. Typically, register changes take effect immediately after the data are written. However, if the registers are part of a group, then the data are written only after all data for the grouped registers in the write block have been sent.

It means I need to write in all GROUP1 registers to make it saved?

So why writing twice into the register work?

Thank you