Dear Bryan

Please refer to my post "ADS1261: Delay time after register write" of two years ago. The project that i'm working on at the present is slightly different in that I have one differential measurement and three single ended measurements. As before, my procedure is nearly the same;

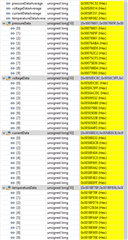

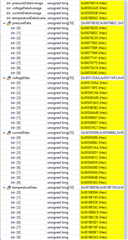

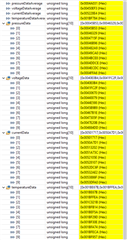

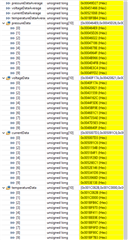

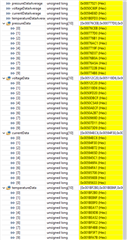

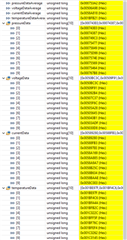

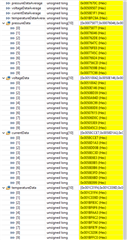

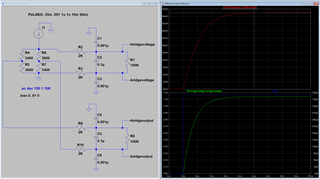

WREG(chn1(PGA,INPMUX)) ---> set START high ---> wait for DRDY ---> RDATA ---> set START low ---> WREG(chn2(PGA,INPMUX)) ---> set START high ---> wait for DRDY ---> RDATA ---> set START low ---> etc.

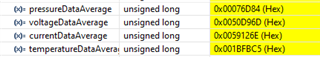

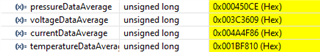

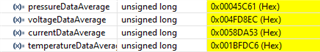

This process, of course, is repeated continuously. While debugging, I noticed that chn1, the first to be sampled, logs that expected value. However, all subsequent samples are not as before. The PGA is set to 16 for the differential, chn1, measurement. For the other three measurements, the PGA is set to BYPASS as required for single ended measurements. If I put a 3.5ms delay before raising the start high, all is it should be. It is noted in sec 9.3.2 of the data sheet, that the PGA is shut down in the BYPASS mode. There seems to be some time required to get the PGA started and settled to the gain of 16. Your thoughts please. Thank you for your time.