Other Parts Discussed in Thread: STRIKE

Hi all,

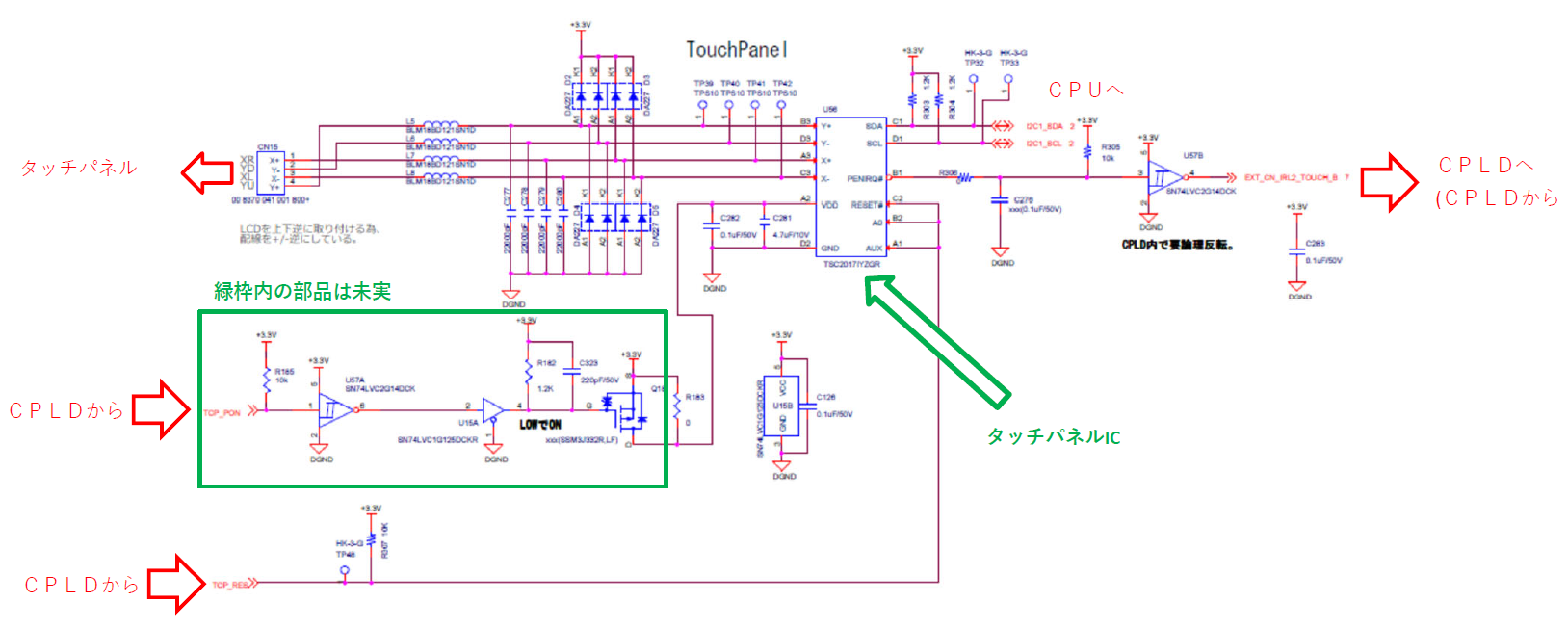

I would like to know test method based on IEC 61000-4-2.

My customer ran ESD test of ±8kV in-air discharge on the finished product.

As a results, the touch screen froze.

I would like to ask you about the details of the test of TI because I want to compare ESD test with the TI test method.

Could you tell me anything about the circuit configuration and the details of the test?

Best Regards.

Ryusuke