i|=SPI2_ReadWriteByte(0x00)<<8;

i|=SPI2_ReadWriteByte(0x00);

SPI2_ReadWriteByte(0x00);

SPI2_ReadWriteByte(0x00);

ADS868X_CS=1;

printf("\r\n%d\ti\r\n", i);

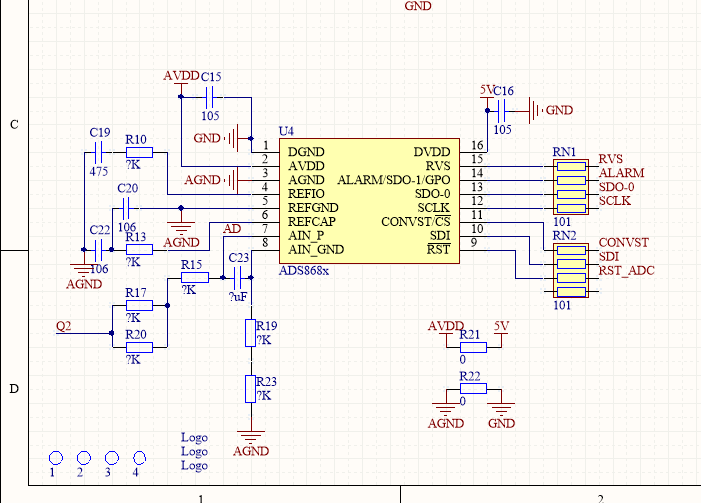

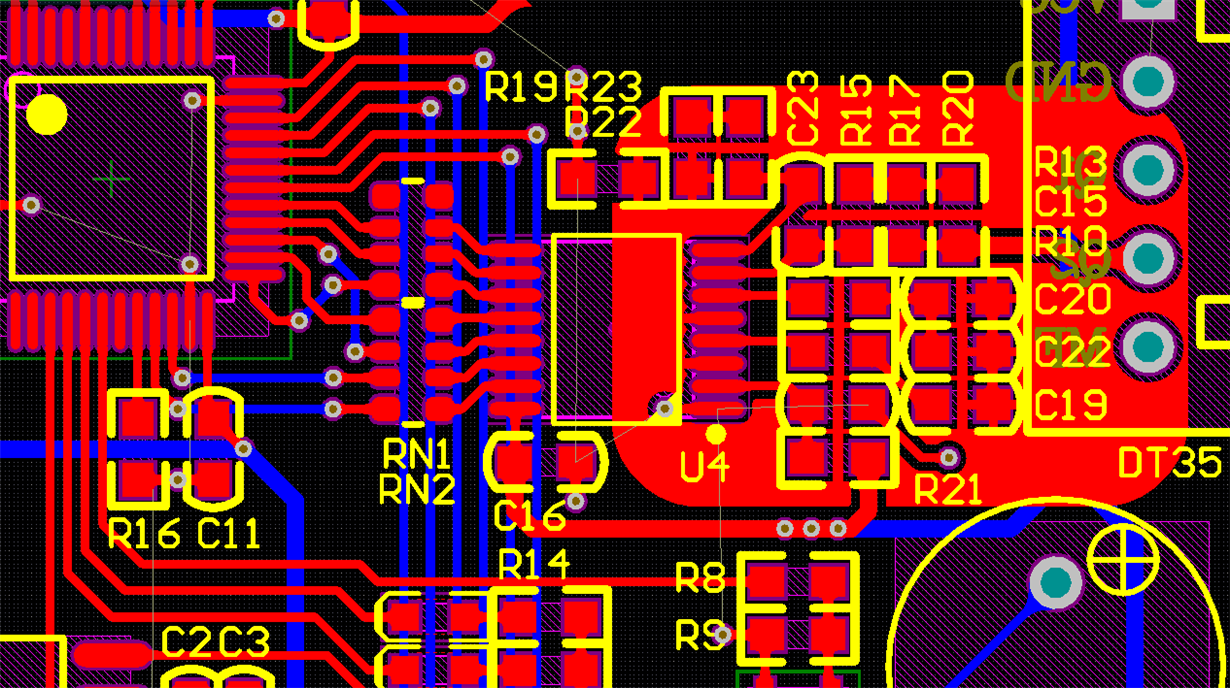

when i use this command ,i set it 0-10.24v i can not get the correct ADC data ,just like it return 16383,while it is 46.6mv