Dear Bob,

Wish you a happy new year. Hope you are doing well.

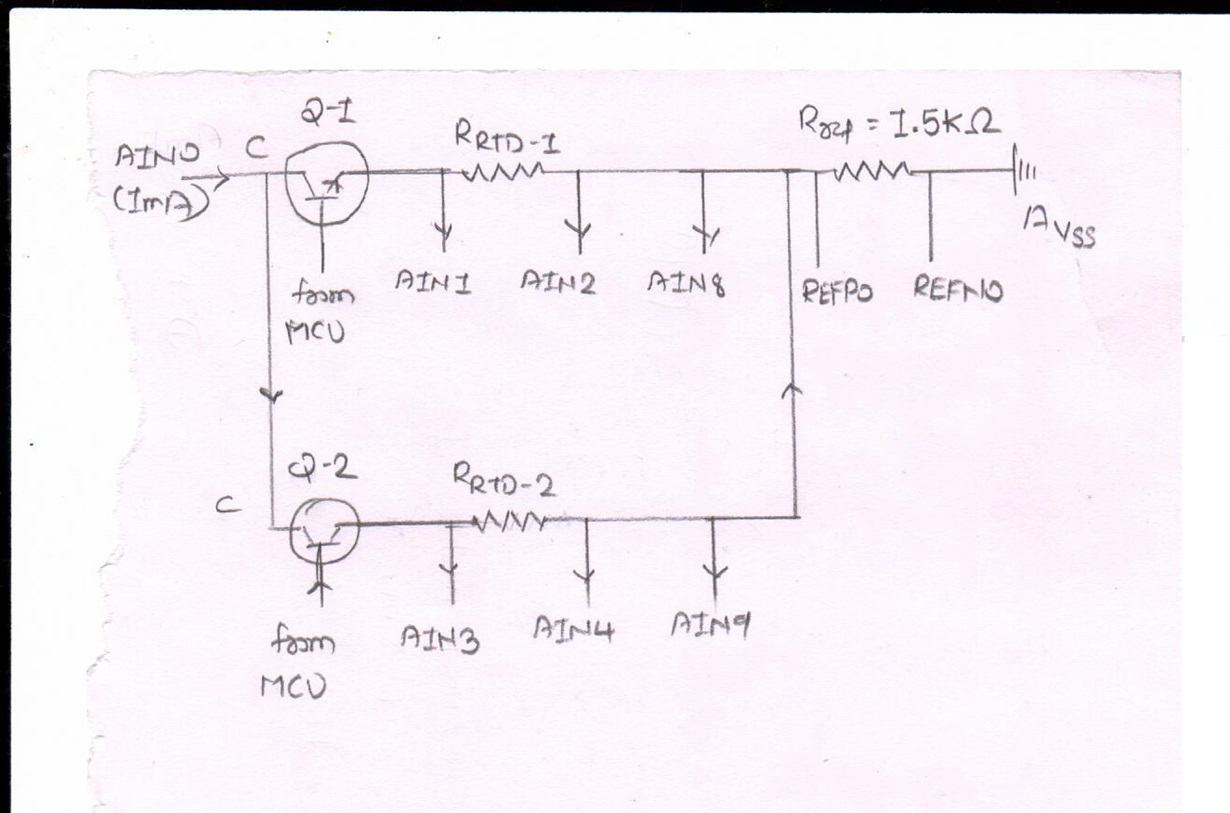

Currently we are measuring Temperature using ADS114S08 and facing problem for RTD Temperature sensors. Here below I gave you detail description for same.

As per "A Basic Guide to RTD Measurements" application note we are using Two-Wire RTD, Low-side reference measurement circuit and Three-Wire RTD, Low-side reference measurement circuit with one IDAC for our temperature measurement.

For First Three Wire RTD measurement register configurations are as follows,

|

Register details |

Data in Hex |

|

REG 01 |

0x00 |

|

REG 02 |

0x12 |

|

REG 03 |

0xEA |

|

REG 04 |

0x9C |

|

REG 05 |

0x12 |

|

REG 06 |

0x07 |

|

REG 07 |

0xF0 |

|

REG 08 |

0x00 |

|

REG 09 |

0x10 |

|

Register details |

Data in Hex |

|

REG 01 |

0x00 |

|

REG 02 |

0x28 |

|

REG 03 |

0xEA |

|

REG 04 |

0x9C |

|

REG 05 |

0x12 |

|

REG 06 |

0x07 |

|

REG 07 |

0xF0 |

|

REG 08 |

0x00 |

|

REG 09 |

0x10 |

Three Wire RTD terminal (A-B-b), A connected to AIN1, B connected to AIN2 and b connected to AIN8.

For Second Three Wire RTD measurement register configurations are as follows,

|

Register details |

Data in Hex |

|

REG 01 |

0x00 |

|

REG 02 |

0x34 |

|

REG 03 |

0xEA |

|

REG 04 |

0x9C |

|

REG 05 |

0x12 |

|

REG 06 |

0x07 |

|

REG 07 |

0xF0 |

|

REG 08 |

0x00 |

|

REG 09 |

0x10 |

|

Register details |

Data in Hex |

|

REG 01 |

0x00 |

|

REG 02 |

0x49 |

|

REG 03 |

0xEA |

|

REG 04 |

0x9C |

|

REG 05 |

0x12 |

|

REG 06 |

0x07 |

|

REG 07 |

0xF0 |

|

REG 08 |

0x00 |

|

REG 09 |

0x10 |

Three Wire RTD terminal (A-B-b), A connected to AIN3, B connected to AIN4 and b connected to AIN9.

As you can see in configuration registers sets, we are using 1mA Exitation current source both RTD Channels. As per our knowledge we can not pass 1 mA current source to both RTD channels at a same time So we are using transistor as a Switching network. So, at a time only one RTD channel will get current of 1 mA from Source pin.

Our program sequence is as follow,

1) start the SPI module

2) configure ADS114S08

3) wait for Vref to settle

4) sending START command to start conversion

5) Turn ON transistor 1 for RTD1 measurement

6) After taking measurement 1 (voltage reading between AIN1-AIN2) & 2 (voltage reading between AIN2-AIN8) for RTD1 Turn OFF transistor 1

7) Turn ON transistor 2 for RTD2 measurement

8) after taking measurement 1 (voltage reading between AIN3-AIN4) & 2 (voltage reading between AIN4-AIN9) for RTD2 Turn OFF transistor 2

9) repeat step-5 to step-8

Here we are using 1.5k ohms precision resistor as reference resistor. Both RTDs negetive side are connected to same reference network.

Let us update is this methode is correct to check tempeature using RTD on multiple AIN inputs? If this is incorrect then kindly give some circuit information which can help us to measure temperature using same IC for 4 nos. of 3 Wire RTD. We are just checking 2 nos of RTD for trial bases. But our end applocation is to measure temperature using 4nos of RTD only.

If you need any further details then let us know.

Waiting for your prompt response.

Thanks and Regards,

Jehan Patel