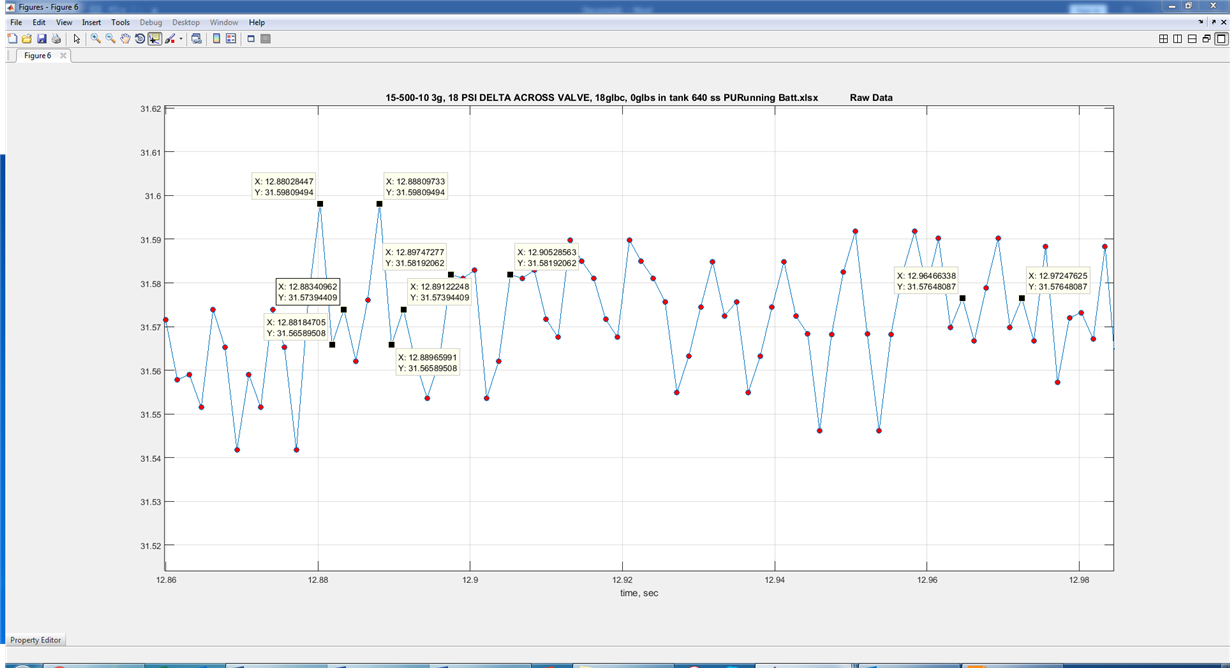

I have a customer using a product of ours with the ADS 1247, and they are trying to measure a pulse that is not much bigger than the noise floor. The problem is that they are seeing sets of 2 repeated data patterns, separated by one or more non repeating data points. The sensor is in continuous sample mode, and the microprocessor is polling the Busy pin before taking another data point. Our custom software takes the data of the device and translates it into process units. I would expect to see repeated data points at the step size of the ADC, but not 3 data points precisely repeated. Any insight?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.